Diversified Fittings’ two twin-spindle/twin-turret lathes are the shop’s most productive machines, offering the highest spindle utilization.

Some shops have names that very accurately describe what they’re all about. Perry, Ohio’s Diversified Fittings is one.

Craig Cogar, who has spent his entire career in the hydraulics industry, started Diversified Fittings in 1997. The shop specializes in machining complex hydraulic fittings and adaptors of all types, focusing on modest batch sizes ranging to 8,000 pieces. An early adopter of CNC technology, nearly half of the shop’s 15 pieces of production machining equipment is chucker lathes. But, with these, it typically has to run jobs across two machines that perform op. 10 and op. 20 work. Not only does this require multiple machines and setups to complete a part but it also requires multiple operators to load and unload parts, and means there’s work in process in various places on the shop floor awaiting secondary operations.

Featured Content

Led by Company President Craig Cogar, the shop specializes in hydraulic fittings and adaptors primarily made from cold-finished steel, stainless steel and brass.

Over the years, Diversified Fittings has mitigated some of this using bar-fed lathes, including a Swiss-type and lathes with integral gantry-style automation. The shop also has a robotic parts loading and handling unit that can tend one of its CNC chuckers, although when batch sizes are low and cycle times are fast, the overall process can be faster by having an operator load the machine.

For years, Cogar had been eyeing bar-fed, twin-spindle/twin-turret equipment, realizing its potential to provide long stretches of largely unattended production. He admits that the price point for such machines compared to a standard turning center (equal to multiple standard turning centers) was initially the sticking point.

However, in late 2020, Cogar purchased the shop’s first twin-spindle/twin-turret machine and just months later (after seeing its advantages) added its second. Not only have these become among the shop’s most productive machines, but they have also reduced cycle times for some jobs by 30 to 50%, lowering overall costs while requiring much less operator oversight.

In fact, their high production and spindle uptime is verified by a cloud-based machine monitoring system the shop has added to all of its CNC machines that identifies and tracks the time when a machine is in-cut and making money and when it instead is sitting idle. And this is done relatively easily by monitoring spindle current draw.

Fitting Additions

Unlike high-volume fitting manufacturers, Diversified Fittings is a 12-person job shop that focuses on smaller batch sizes for parts commonly produced from cold-finished steel, stainless steel and brass. The two twin-spindle/twin turret machines the shop added were Doosan Puma TT1800SY models, purchased through Ellison Technologies Ohio. Cogar has worked with Matt Bujoll, Ellison Technologies Ohio president, for a number of years. Knowing Cogar and Diversified Fittings so well, Bujoll knew that these machines would have a big impact on the shop’s efficiency and bottom line. Despite the cost, he knew the return on investment would come quickly.

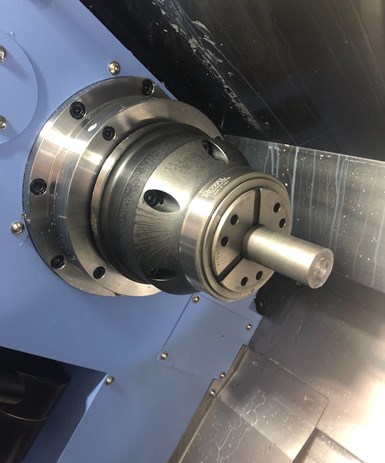

Each twin-spindle/twin-turret machine has quick-change collet systems to help speed setups.

Each of these machines feature 30-hp, 5,000-rpm main and subspindles as well as turret motors rated at 7.5 hp and 5,000 rpm. The 2.6-inch barstock capacity aligns with most of the part sizes the shop produces. Diversified Fittings chose to fit these machines with 4-foot LNS Alpha SL65 S bar feeders, feeling that shorter bars are easier to handle and put less stress on the main spindles than longer bars would.

In addition, each of the machine’s two turrets has 12 tool stations. This enables the shop to leave a variety of tools loaded in the machine to accommodate different jobs/families of parts to speed changeovers or maintain redundant tooling for long-running jobs so production doesn’t have to stop for tools to be manually replaced due to wear.

Setup time is further reduced because each machine uses quick-change collets from Royal Products. With these, barstock gripping range is 0.0625 inch (Cogar says he often can fit three different-sized hex bars in a given collet size) and collet changes are said to take only 10 seconds.

Each machine offers two ways completed parts can be removed. One is a part catcher at the front of the machine, but the shop only uses that to collect barstock remnants. Instead, completed parts exit the side of the machine via a conveyor, which is a standard machine feature.

The shop chose a 4-foot bar feeder for easier barstock handling and less stress on the machines’ main spindle compared to longer stock.

In terms of programming this new type of machine, Cogar says the shop benefited by having SolidWorks for creating its CAD models and SolidCAM for offline machine programming. Among other advantages, he says SolidCAM minimizes the risk of human error, such as manually entering a negative X value when it should be a positive X value for a given turret.

Diversified Fittings also benefited by having application engineers from Ellison Technologies Ohio train personnel on the machine and program a few initial jobs. The shop also has brought in the company’s engineers to review existing part programs for long-running jobs in order to identify ways to further reduce cycle times. Shaving 10 or 20 seconds off part production for a large batch size can make a big difference, Cogar notes.

Monitor, Too

The twin-spindle/twin-turret machines were brought in to speed production. Watching these machines in operation, as I recently did, seemingly shows this, but basic machine monitoring technology measures and proves it.

Machine monitoring technology enables Diversified Fittings to compare actual daily production to expected production (as shown here) as well as track individual machine uptime.

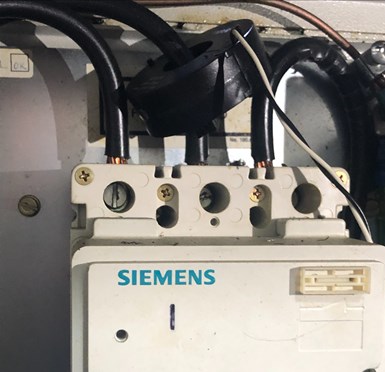

In 2018, the shop began installing machine monitoring technology from Machine Tracking to track spindle in-cut time for all the shop’s CNC equipment. This technology uses what Machine Tracking calls Machine Utilization Sensors (MUTs) that install around a power leg within a machine’s electrical enclosure. These sensors determine whether current is being drawn by a machine’s spindle (meaning the spindle is cutting) or not (meaning the spindle is idle). That data is transmitted to the cloud, processed and made available to the shop on machine monitoring dashboards which are accessible via various devices such as computers, smartphones and tablets.

Basic machine monitoring technology measures and proves production levels.

Initially, this gave the shop a baseline as to the actual production time (for example, in-cut time) each machine was achieving each day. Next, the shop was able to determine the best next steps to increase uptime for each machine. Cogar says he shoots to reach 90 hours a day of machine cutting time. For most jobs, the twin-spindle/twin-turret machines achieve 95% uptime, he notes. But the machine monitoring system also helps identify production anomalies. For example, if a setup that’s expected to take one hour takes three hours, the shop can look into what might have caused this problem so as not to have the issue repeat.

Sensors inside the control panel are used to read electrical current to determine whether current is being drawn by a machine’s spindle (meaning the spindle is cutting) or not (meaning the spindle is idle).

Photo credit: Machine Tracking

Diversified Fittings is also in the early stages of implementing technology to be used on its seven CNC chuckers that displays on large monitors in the shop the time remaining in the current cycle on each of those machines. This technology uses codes in the machining program that sends an output when the spindle starts and stops. That way, operators can see at a glance from wherever they are on the shop floor when a part is about to be completed on a machine and ready for unloading. The goal is to minimize the amount of time a chucker is waiting for an operator to unload the completed part and load material for the next cycle. Plus, because most who work on the shop floor can operate various types of equipment, one operator can cover for another who is away from the machine for whatever reason after noticing the display showing the machine is sitting idle.

RELATED CONTENT

-

New Line of Swiss-Types for Job Shops Eyeing High-Production Work

Mazak now offers the Syncrex line of Swiss-type CNC lathes — its first — targeting machine shops getting into higher volume production of complex parts.

-

Making Parts on a Swiss/Laser Machine

Adding laser cutting to Swiss-type machining is helping this shop do more work for its customers in the medical industry.

-

Advancements in Thread Whirling Tooling Technology

Many understand the advantages of thread whirling on a CNC Swiss-type. However, new tooling technology for this thread-machining process can further improve cycle times and reduce cost per part.