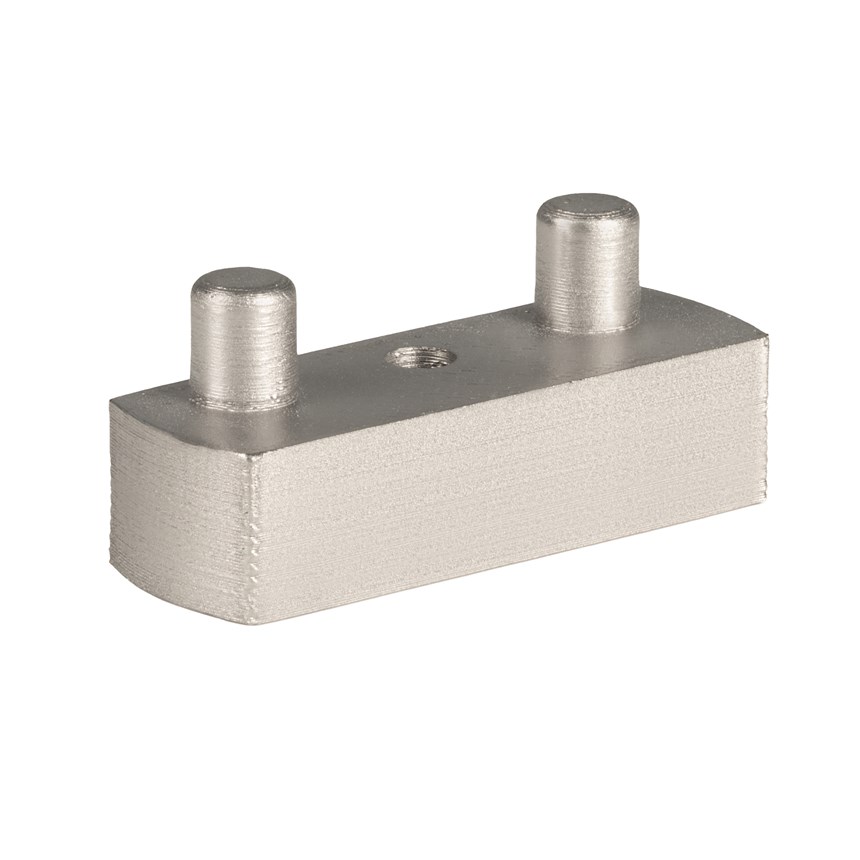

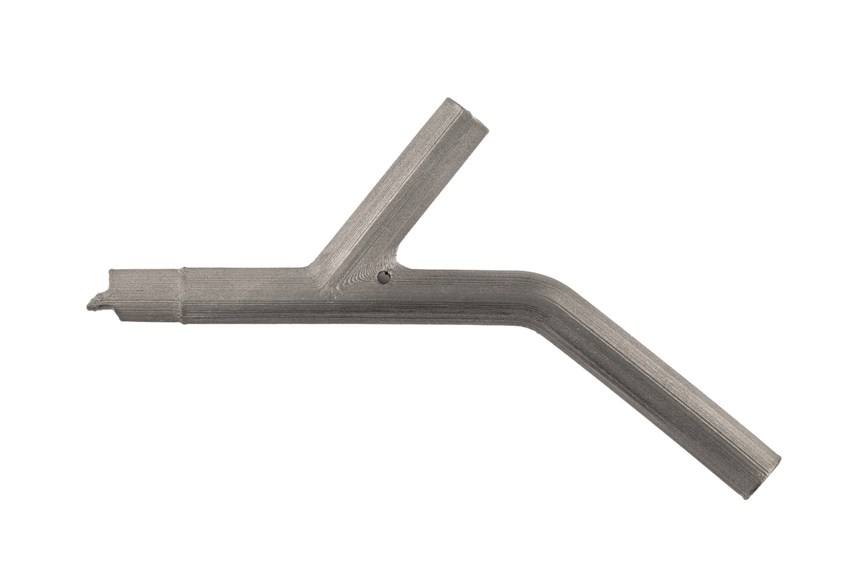

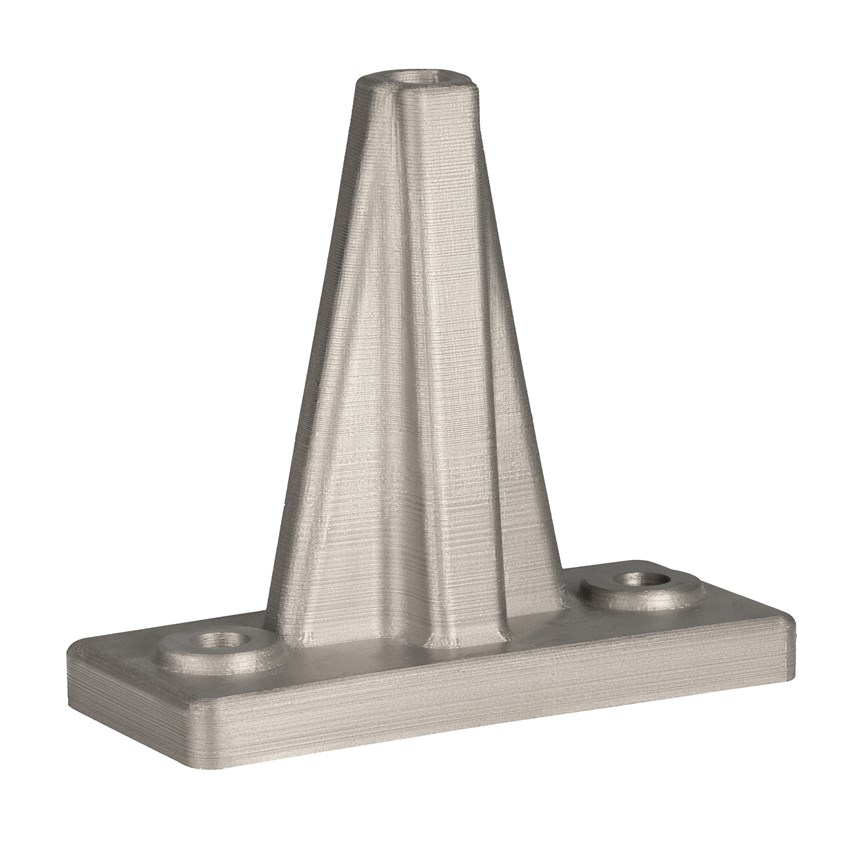

parts made by Eaton Corp. using 3D printing system

This 3D-printed stainless steel robot gripper is used to automatically load a gear hobbing machine so it can perform a gear chamfering operation. Eaton Corp. saw a 90% cost savings by using Desktop Metal’s Studio System compared to using traditional subtractive machining to create this gripper. Photo Credits: Desktop Metal

Like many other automotive suppliers, Eaton Corp.’s Industrial Sector, Vehicle Group, endeavors to minimize downtime on its tooling and fixturing manufacturing lines to keep up with the rapid iteration of vehicle design and the worldwide demand for automotive parts. Besides mass production, the company also produces one-off, custom solutions for customers around the globe.

Therefore, figuring out how to best retool manufacturing lines quickly and efficiently was a priority, but it also strived to develop and prototype custom parts for transportation challenges fast and proficiently. To do so, company engineers turned to Desktop Metal’s original Studio System — a metal 3D printing system designed for an office space that includes three separate pieces of equipment: the printer, debinder and furnace.

Featured Content

The Studio System’s impact at Eaton was immediate. With the ability to quickly print a variety of tooling and fixtures — from a complex set of pneumatic jaws used in a gear chamfering process to relatively simple press tools — engineers were able to cut the lead time for tooling by more than 60%. Lead times went from three to four weeks to only five to 10 days.

Also, depending on the size and design complexity, printed tools are, on average, between 40% and 80% less expensive to manufacture compared to using subtractive or traditional manufacturing.

In addition, company designers can use additive manufacturing to explore new levels of design complexity and create parts that include internal channels.

With the ability to address customer needs faster and iterate parts quickly, the system is now standard within the workflow for both the engineering and toolroom teams, and is used daily to support operations around the globe.

“Before additive manufacturing, I was afraid to fail,” says Alex Abernethy, senior engineer at Eaton Corp. “After additive manufacturing, if you fail it happens quickly, and you can correct the error more quickly.”

Though Eaton had years of experience using polymer printers, the company began searching for a metal 3D printing system that could support its shop floor. The company chose to invest in the Studio System due to its ability to significantly reduce the cost and lead time to produce tooling and other parts, as well as its ease of use and office-friendly design. Because it uses no loose metal powders or dangerous lasers, operators don’t need personal protective equipment.

Desktop Metal calls its additive technology Bond Metal Deposition. BMD is a metal additive manufacturing process that uses bound metal rods made from a combination of metal powder and a wax and polymer binder. In the BMD process, these filament-like metal rods are fed through a heated extruder onto a build plate, layer by layer, until a green part is built.

Then, as the second step in the company’s original Studio System 3D printer, the green part is placed into a debinder, where a fluid dissolves the primary binder in preparation for the third step — sintering. The system’s sintering furnace, which works like a traditional sintering furnace used in powder

“Before additive manufacturing, I was afraid to fail,” says Alex Abernethy, senior engineer at Eaton Corp. “After additive manufacturing, if you fail it happens quickly, and you can correct the error more quickly.”

metallurgy processes, finishes the debinded part. This is the system used by Eaton, but Desktop Metal’s latest technology eliminates the need for a debinder (more on that later).

With the ability to address customer needs faster and iterate on parts quickly, the system is now a standard part of the workflow for both the engineering and toolroom teams, and is used daily to support operations around the world. The system has become so successful that Eaton is now exploring the idea of investing in binder jetting technology for production parts.

The original Studio System is a three-step 3D printing system which consists of the printer, debinder and a furnace. This is the system that Eaton used, but the latest technology from Desktop Metal eliminates the need for a debinder.

The parts Eaton has printed using Studio System fall into four categories: gripping, components, testing fixtures, and tooling and replacement parts.

- Gripping Components. Because many of its traditional machine tools run around the clock, Eaton engineers strive to increase their productivity. One approach has been to automate some processes, including using robotic arms and custom grippers to hold workpieces during loading and unloading. Printing grippers resulted in reducing manufacturing lead time and part costs, while simultaneously reducing the logistical and operator burdens of traditional manufacturing methods

- Testing Fixtures. The Studio System also proved to be an effective tool for producing custom fixturing. Before shipping products to customers, Eaton conducts regular tests to ensure its products meet stringent standards and work as intended. Many of those tests demand unique fixturing, which is almost always produced in low volume. Printing those fixtures using the Studio System has been a value-added process, enabling the company to save both time and money, and reduce the logistical burden associated with traditional manufacturing methods and supply chains.

- Tooling Components. Many high-volume manufacturing processes rely on hard tooling, which are generally among the more expensive and time-consuming parts to produce. By printing that tooling using the Studio System, Eaton has reduced lead times and costs for these tools.

- Replacement Parts. As with other manufacturing facilities, Eaton must constantly maintain its equipment and replace parts as they become worn or broken. To avoid extended periods of downtime while waiting for replacement parts, the company must either keep many replacement parts on hand or pay a premium to have the parts made quickly via traditional methods. The Studio System, however, offered another option. Using 3D scans of parts, Eaton engineers were able to reverse engineer models of several parts where drawings were not available and adapt existing designs for printing. Using the 3D printing system, the company was then able to produce replacement parts in days, which is much faster than traditional manufacturing. The printed parts were also up to 90% less expensive than their traditionally machined counterparts.

From 3 Steps to 2 Steps

Desktop Metal’s latest metal 3D printing system, Studio System 2, includes only the printing and sintering processes with a software-controlled workflow. New material formulations enable printed parts to be placed directly into the furnace, without the need for the typical solvent debind phase.

With the company’s Fabricate software, native to Studio System 2, all aspects of part creation are automated. The software automatically scales the part, orients it for the print and sintering process, generates separable supports, and applies expert metallurgy to optimize fabrication, the company says.

The Studio System 2 also automatically generates seams throughout support structures and prints a reformulated ceramic interface material between the support structure and the part, enabling parts to easily be removed by hand.

This technology also enables users to change printheads by pressing a button, and change materials quickly with a refillable cartridge system during print jobs.

RELATED CONTENT

-

A 'Microscopic' Look at ISO 16232 Standard Analysis

This article gives three key points that should be confirmed with a microscope support team or within microscope software to ensure that proper settings are in place to detect, measure and categorize most particles for automotive manufacturing.

-

Custom Tooling, Workholding Help Whip Rotors Into Shape

Whipple Superchargers uses unique form tools and dead-length-collet workholding for its B-axis turn-mill enabling it to create more accurate rotors for its brand of engine power-adders.

-

Attaining Ten-Millionths Bore Accuracy

Conventional honing has been continuously improved and automated, now allowing boring accuracies to be measured in millionths.