How Fast Can You Change Over a Multi-Spindle?

Today’s CNC multi-spindles feature design elements that enable these high-production machine tools to be effective for lower-volume jobs that require more frequent setups.

Daily demonstrations in Index’s Booth 339119 in the South Building show how fast a CNC multi-spindle can be changed over from one job to another.

When most think of CNC multi-spindle machine tools, very high production runs of one part or a family of very similar parts often comes to mind. In these cases, setups for new jobs are few and far between. These days, though, CNC multi-spindles are increasingly being used in what might be considered job-shop environments, whereby batch sizes for a particular job might be much smaller to meet customer delivery requirements.

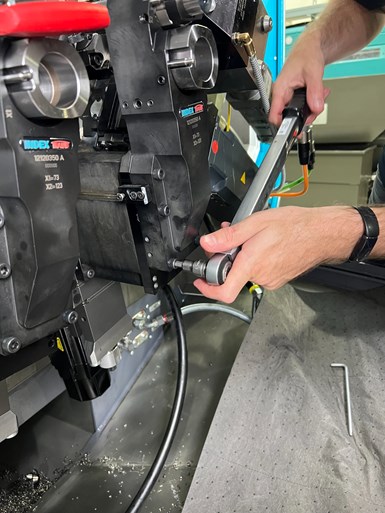

That’s why CNC multi-spindle machine builders are building flexibility into their designs to facilitate faster changeovers to new jobs. Index Corp. is one example. In fact, it highlights this in daily demonstrations in its Booth 339119 in the South Building in which a MS32-6 multi-spindle is changed from one job to another to create two mating parts that connect to form an assembly.

Featured Content

It doesn’t take as long as you might think, and one key design element to facilitate fast changeovers is the company’s patented W-serration feature on tooling slides. This locating system enables users to simply loosen a holding screw and remove the current slide, then position a new slide and tighten its holding screw. The W-serration system automatically ensures proper positioning to micron-level alignment accuracy. Plus, tools can be preset (measured) ahead of time off the machine.

After you catch this demo, you might see the latest version of the Index’s B-axis G220 turn-mill now with a second lower turret meaning three tools can be in the cut at once. Similarly, its Traub TNL 12 Swiss-type now can have 4 tools cutting simultaneously. In addition, ask about iXworld, the company’s cloud-based platform that covers researching specifications during the purchasing process, monitoring and optimizing operations, requesting service for the machine and more.

For example, the iX4.0 apps include EquipmentApps for full, transparent information on a shop’s entire machine fleet; StatusApps to help maximize machine utilization; ConditionApps to ensure machine availability; and JobApps to determine costs per production job and document quality parameters. In addition, iXservices is the Index service platform that includes in-person on-site visits, remote online services calls, or service hotline calls while iXshop makes it easy and efficient to order replacement parts from an online catalog of more than 130,000 products.

Index’s booth is a good example of how hardware and software technology can come together to boost a machine shop’s production efficiency and, ultimately, its profitability.

RELATED CONTENT

-

How to Get More Efficient Production from Swiss-Type and Multitasking Machines

SolidCAM for multi-axis Swiss type and multitasking machines provides a very efficient CAM programming process, generating optimal and safe Mill-Turn programs, with dramatically improved milling tool life.

-

What’s Still Cam-Driven and Why?

Combining select cam-driven functions with CNC technology for this multi-spindle platform is said to help reduce machine cost while retaining high machining speed, precision and production.

-

Shop Evolves with CNC Turning

Debbie Sommers answered a newspaper ad for a receptionist job at a South Elgin, Illinois, screw machine shop in 1980. Today, she owns the shop, an 18,000-square-foot facility with 20 employees and sales growth of 25 percent in 2017.