It’s time to reunite with the precision machining industry at the Precision Machining Technology Show (PMTS) 2023 set for April 18-20, 2023, in Cleveland, Ohio, at the Huntington Convention Center. It’s where you can share challenges and insights, see new technology solutions and learn about process innovations – everything you need to take back and immediately put to use in your own shop.

Production Machining wants to help kick off your research with a series of PMTS Product Previews. In this group, we’re taking a look at high-volume turning, including a fixed headstock-type CNC automatic lathe that has a variety of features to improve machine operating convenience; a multitasking machine with superimposed machining that enables shops take on complex contracts; a high-precision production lathe that features a FANUC digital control, compact size and flexibility for cost-effective, small- and large-scale production runs; and more.

Before you go to the show, don’t miss PMTS show highlights in Derek Korn’s PMTS feature article and look for more PMTS Product Previews each week until the show! And don’t forget to register for the show.

If you would like to learn more about the latest news, product technology and operational best practices in the precision machining industry, consider subscribing to Production Machining's free monthly print magazine.

Click on each link below to read the full product post:

Photo Credit: Marubeni Citizen-Cincom

The Marubeni Citizen-Cincom Miyano ANX-42SYY fixed headstock-type CNC automatic lathe is equipped with the low frequency vibration (LVF) technology option for reduced chip entanglements. The LVF technology is now available as an option on the Miyano ANX model. Machine operating convenience has been improved, including compatibility of operations that assures ease-of-use even for users of the Cincom brand in addition to those of the Miyano brand.

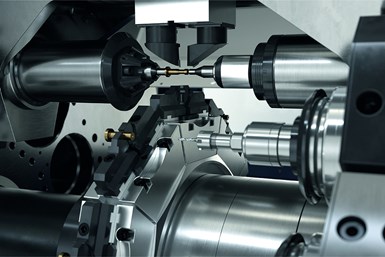

Photo Credit: Methods Machine Tools Inc.

Methods Machine Tools Inc.’s Nakamura-Tome SC-100X2 twin-turret multitasking machine uses two tools on either side of the upper turret for superimposed machining, making it especially useful for machining Swiss-type parts larger than 25 mm in diameter. Superimposed machining enabled by this machine lets shops take on complex contracts and more jobs – all while completing them in a fraction of the time – compared to other machining methods, the company says.

Photo Credit: Schaublin Machines

Schaublin Machine’s 302 machine is a high-precision production lathe with a FANUC digital control. It features a compact size and flexibility for cost-effective small- and large-scale production runs. This multipurpose machine is well suited for prototyping, which often requires great flexibility and versatility. The machine is features a FANUC 0i-TF control system. It has been designed for easy installation of an automated loading system with robotic part loading available as an option.

Esco’s Escomatic D6 CNC Ultra automatic lathe maximizes the number of operations in one machine to streamline and increase production. The tool head rotates up to 12,000 rpm and has three cutting tools that can be controlled separately, as needed, to offer more possibilities and simplify the process. The lathe is capable of handling a variety of materials for the production of small-diameter parts.

Tajmac’s Penta TMZ 518 is a five-spindle automatic lathe with an island concept that complements Tajmac-USA’s line of full CNC six- and eight-spindle machines. The island concept offers the machine as a package which includes the machine, oil treatment system, chiller, chip conveyor and bar feeder. The design creates a single-source supplier contact for all those components. The included bar loader is a custom-designed loader developed by Cucchi BLT, another member of the Tajmac Group. The enclosed loader has the capacity to run five 12-foot-long bars, up to 18 mm in diameter.

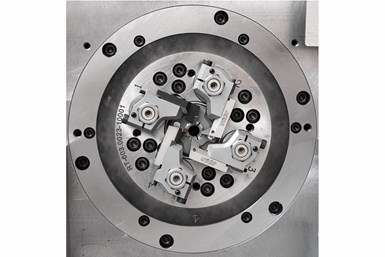

Photo Credit: Winema Transfer Machines

Winema says its precision turning cell (PTC) within its RV 10 Flexmaster rotary transfer machine enables users to machine the entire external contour of a workpiece without positioning errors, accurate to a micron level. The robust PTC is integrated in the machine as a disconnected turning cell and is free of the drive and machining factors that affect the other stations. With the PTC, the company says users can achieve the highest levels of concentricity precision with internal and external turning.

The Spinner PD-CNC lathe is a rigid, compact, high-precision lathe with an accessible work area, optional linear tooling and/or turret with driven tools. With a footprint of only 43" × 85", the PD’s submicron high-precision enables users to hard turn parts >60 hrc with perfect surface quality and optimal form tolerance. This lathe can achieve high levels of precision due to features such as its high-precision spindles, pneumatic clamping cylinders with programmable clamping force, glass scales in all axes, ultraprecise ball screws, and hardened and ground sliding vibration-damping guideways.

Landscape Source: Tajmac

RELATED CONTENT

-

Buying a new CNC Swiss turning center is a substantial investment. For the best return, look closely for capabilities that enable the best utilization of the machine.

-

Here’s an example of a shop applying innovative probing, tooling and workholding strategies to enable its turn-mill to machine castings complete.

-

Threading is usually the last operation when machining components, which is why the process needs to be reliable and highly precise. DC Swiss has developed an internal thread whirler, which leaves micro threads burr-free, even in demanding, hard-to-machine materials.