Grinding for Precision Machining

Grinding machines use rotating, abrasive wheels that take light cuts — not so much for high material removal, but to create a better surface finish than can be achieved by milling or turning operations. Grinding is commonly one of the last machining operations performed to complete a part. Cylindrical and centerless grinders are used for cylindrical parts. Grinding machines for flat surfaces are called surface grinders. Form grinders move the work and/or the wheel in various axes to grind surfaces that are precisely contoured. Grinding machines are also used to create and sharpen cutting tools. Advances in grinding wheel technology continue to improve grinding speed, part surface finish and wheel life.

Latest Grinding Articles

VIEW ALLCarbon Fiber Spindles Aim to Eliminate Grinding Variance

These spindles available on Tschudin CNC centerless grinders are designed to minimize the heat transfer factor while optimizing dimensional stability and material removal rate.

Read MoreJunker Grinding Machines Feature Modular Design

The Platform 3 series of modular grinding machines is designed to provide increased flexibility and cost-effectiveness.

Read MoreEmag Grinding Solutions Provide Precise Gear-Profile Grinding

The G 160 and G 250 gear-profile grinding machines provide short chip-to-chip times, intelligent axis concepts as well as thermal and mechanical stability.

Read MoreShould You Bring Tool Regrinding In-House?

In some situations, the potentially high investment in an in-house tool grinding process can be justified with a relatively fast ROI. (Includes video.)

WatchTooth Flank Grinding Technology Minimizes EV Drive Noise

Drives for electric vehicles require gear components with tight tolerances and excellent surface finishes. Even minimal ripples in the surface of tooth flanks on shafts and gears can cause interference noise in drive performance.

Read MoreStuder S100 Grinding Machine For High-Precision, Flexible, Reliable Grinding

The machine is well suited for a wide range of internal, surface and external grinding applications, making it well suited for the entry-level market.

Read MoreLatest Products

Grindstar Replaces Turning With Efficient Grinding

PMTS 2023: The Grindstar machine uses a method that enables the entire workpiece contour to be ground in a single processing operation.

Read MoreCylindrical Grinder Shows Off High Precision

The United Grinding Studer S131r cylindrical ID-radius grinding machine targets tough ID grinding operations and a range of hard-to-machine materials.

WatchHigh-Precision Grinders Capture Optimal Surface Finishes

Okamoto Corp.’s ACC-SA1 series and ACC-32·80CHiQ grinding machines are designed to provide precision, flatness and smooth surface finish.

Read MoreOne 5-Axis Tool Grinder With Flexible, Scalable Design

Multi-axis CNC tool grinding machine features a scalable, modular design, making it retrofittable with any option.

Read MoreGrindSmart 660XW Hybrid Machine for Ultralean Grinding Processes

Rollomatic’s GrindSmart 660XW is a hybrid, 6‐axis tool and peel grinding machine that enables users to utilize cost‐effective and advanced lean manufacturing principles for ultralean grinding processes

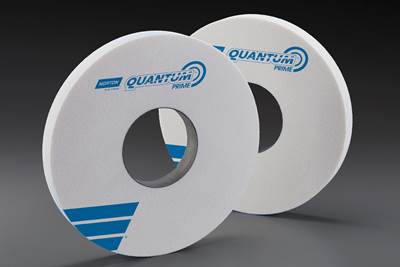

Read MoreNorton’s Quantum Prime Grinding Wheels Offer Enhanced Efficiency, Part Quality

The wheels are said to feature a microfracturing grain that has unparalleled sharpness and cutting efficiency to reduce power draw and cycle times, while increasing material removal rates.

Read MoreFeatured Posts

The Advantages of Turning and Grinding on One Machine Platform

Instead of using a dedicated grinding machine or an outside grinding vendor to achieve very high surface finishes, a machine that can hard turn and grind can reduce WIP and speed part completion while taking up minimal floor space.

Read MoreAutomation in the Alps: Studer AG Unveils New Grinding Concepts

Studer AG, member company of United Grinding, held its annual press conference at its Swiss Alps location earlier this month to announce its new automatic loaders to accompany its existing grinding machines as well as other offerings and automation features.

Read MoreWhat is CNC Peel Grinding?

It resembles single-point turning on a lathe because, similar to a lathe’s tool, the grinding wheel moves in the X and Z axes to grind contours, diameters and other features.

Read More5 Grinding Considerations for Improving Surface Finish

Improving surface finish can be done by making adjustments to one or more of these points: operational parameters, wheel dressing, grit size, coolant delivery and machine condition.

Read MorePrecision Machining Technology Review November 2022: Grinding

Production Machining showcases some of the latest grinding technology from United Grinding, Rollomatic, Norton | Saint-Gobain, Star Cutter Co., Strausak and Okamoto Corp.

Read MoreEstablishing an Effective Production Process for Femoral Balls

Grinding, honing and buffing can be performed on one machine to eliminate the need for these medical implant components to run across multiple pieces of equipment.

Read MoreGrinding Supplier Categories

- Surface, Reciprocal Table

- Thread

- Wheels & Belts

- Grinding Wheels & Belts

- Disc, Single or Double

- Abrasive Belt

- Creep Feed

- Cylindrical OD

- Grinding Wheel Dressing Units

- Grinding Wheel Dressing Units

- Centerless

- Tool, Cutter & Drill Point

- Profile

- Jig

- Surface, Rotary Table

- Internal Cylindrical

- Attachments & Accessories

- Universal (ID/OD)

.jpg;maxWidth=300;quality=90)