Transfer Machine Features Independent Turning Cell

Isolated turning cell within transfer machine is free of the drive and machining factors that affect the other stations.

Edited by Derek Korn

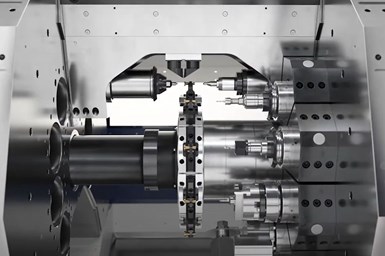

Winema says its PTC (precision turning cell) for its RV10 Flexmaster transfer machine enables users to machine the entire external contour of a workpiece without positioning errors to micron-level accuracies. The PTC is integrated in the machine as a disconnected turning cell and it is free of the drive and machining factors that affect the other stations. It is said to provide high concentricity precision with internal and external turning.

As a closed, vibration-damped cast design, the PTC can transfer the workpiece into an independent coordinate system where it can perform a turning process in isolation. When turning between centers, accurate concentricity remains consistent down the entire length of the workpiece. If a workpiece is held in a collet chuck by the PTC, tight positional tolerances can also be maintained between external and internal contours. The PTC features two turning tools with Capto interfaces and three PTCs can be integrated into each machine.

RELATED CONTENT

-

Captive Shop Must Still Compete

Often, a captive shop seems to have it made by job shop standards. In the case of this division of ITW Welding, “work is not given, it’s earned.”

-

Automated Manufacturing in the U.S. Makes for a Fitting Process

An Australian company has been able to speed delivery of its popular plumbing products to U.S. customers by adding machining and assembly cells to produce brass fittings in Alabama.

-

Beyond One and Done

Rotary transfer machining is one proven solution for high volume machining. Today’s CNC rotary transfer machines provide more than “set it and forget it” production; they are flexible enough for high mix and low volume production demands.