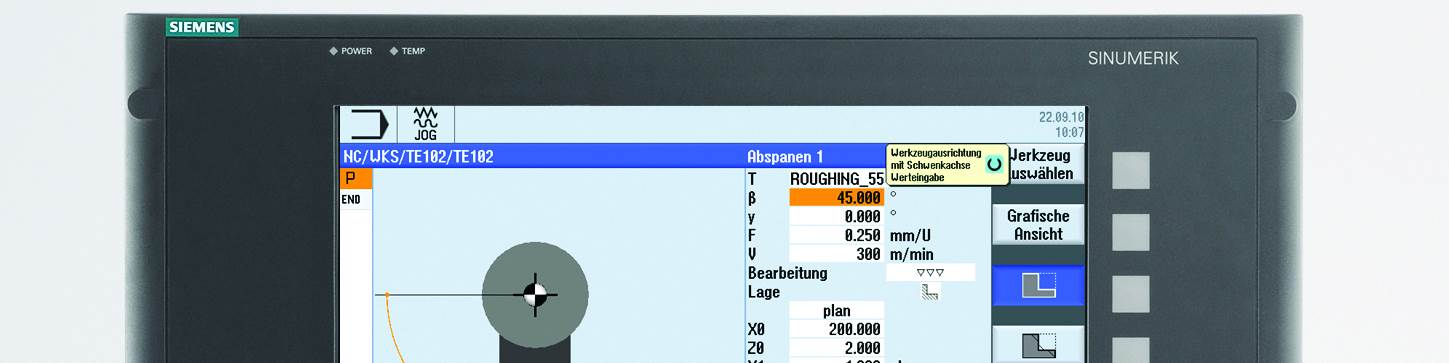

When CNC G-Code Programming Is a Must

In some cases, G-code programming is preferred over conversational programming, although they can be complementary processes.

#techbrief

Siemens Offers Virtual Product Expert for CNC

The program enables all Siemens CNC community members to interact with a product expert and get answers to programming and operations questions on-demand.

CNC Control Simplifies Programming, Part Setup

A redesigned graphical interface makes it easier for users of all levels to manage programming and part setup, and provide simplified machine operation.

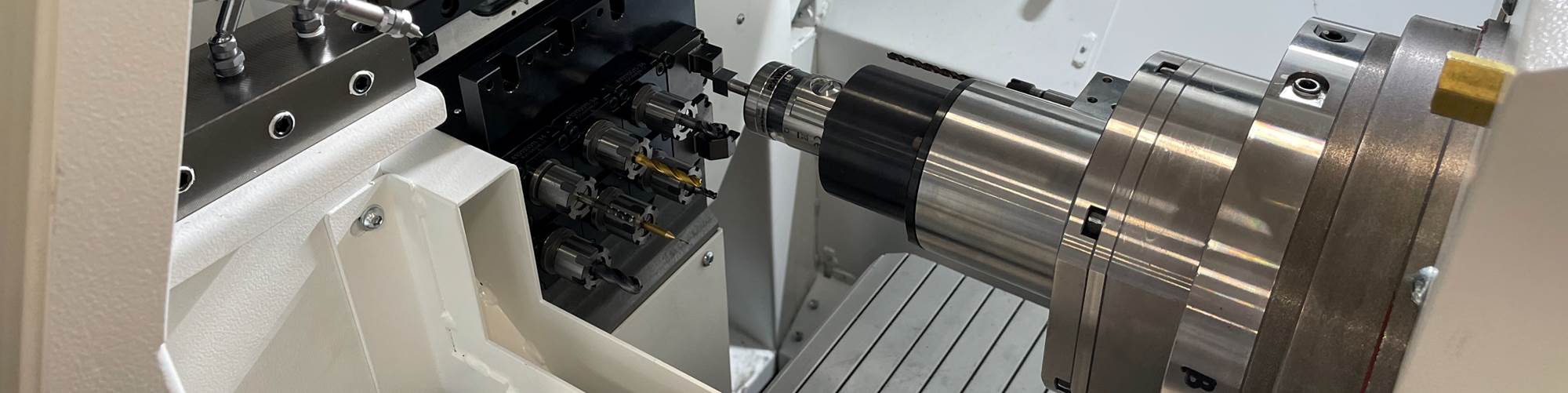

CNC Oscillation Cutting Function Eliminates Metal Strand Buildup

The Vibration Cutting Control on the M8 Series CNC breaks up long strands of material that are expelled from the part being produced to speed up processes, reduce cycle times and provide a better finish on the part being produced.