6 Trends in Production Turning

Production shops are increasingly relying on technology and innovation to enhance competitiveness and deal with the scarcity of skilled workers. Here are six of the most most important ways they are going about it.

For all the recent emphasis on strengthening local supply chains, little of that can happen if the shops themselves aren’t up to the requirements of serving customers in an ever-changing manufacturing environment. Fortunately, many shops are rising to the challenge by investing in new technology and processes that reduce cost, improve flexibility and provide the responsiveness their customers increasingly demand.

What follows is a small sampling of topics, technology and trends beyond the universal skilled labor shortage which I believe to be on the minds of owners and managers of production machine shops. In effect, these represent subject matter that perhaps we should cover more in Production Machining magazine. What I’d ask of you is to let us know if there are other topics we should be covering on a more regular basis.

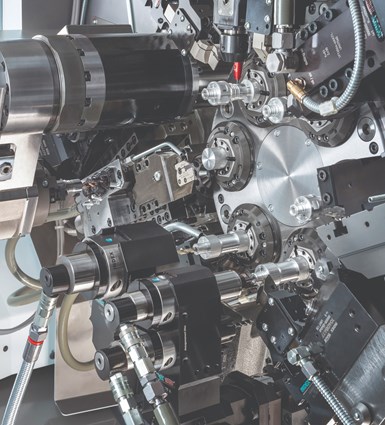

The Index MS32-6 multi-spindle lathe features a new tool slide platform that uses a W-serration interface and quick-clamping system to enable fast changeovers.

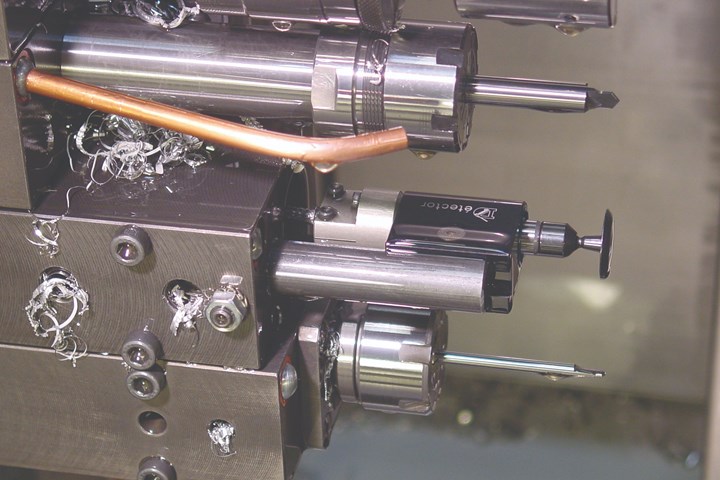

- Automation is more than robots. This is one trend highlighted in the article “Precision Machining Technology Moving Shops Forward.” Certainly, robots are shedding the bad reputation of the past as they are now more flexible, easier to program and, in some cases, re-deployable to various machines. Shops are also looking more at equipment such as tool presetters, on-machine part and tool probing, and in-process gaging to eliminate manual tasks (and the risk of error) from the machining process.

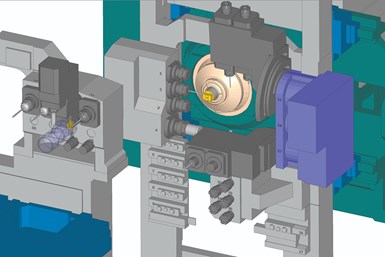

- High-production machines are becoming more flexible. While part volume requirements for production shops remain high, flexibility to pivot to different jobs is becoming more important. (An example of this was the need for shops to supply much-needed ventilator parts in the fight against COVID-19 even though they hadn’t previously produced them.) Builders of Swiss-types, multi-spindles and rotary transfer machines recognize and are modifying machine designs accordingly to be more versatile.

Esprit uses an artificial intelligence engine as a means to “build intelligence” into CAM programming for a range of machine tools including Swiss-types. Creating accurate, digital twins of actual machines with data of machine kinematics is a key part of this, too.

- Focus is shifting from hardware to software. Basic physics means machine tools have effectively hit the ceiling in terms of how fast they can remove material, their spindles can rotate, their axes can move and so on. This has shops looking more to software to boost overall process efficiencies. More capable and intuitive enterprise resource planning (ERP) software is becoming a big part of this. But, so is the ability to more easily pull data from machines, benefit from sensor technology to enable more adaptive machining and perform statistical process analysis. More shops will be hiring IT personnel to handle data analysis and equipment interconnectivity moving forward. Effective process control for high-volume operations is imperative.

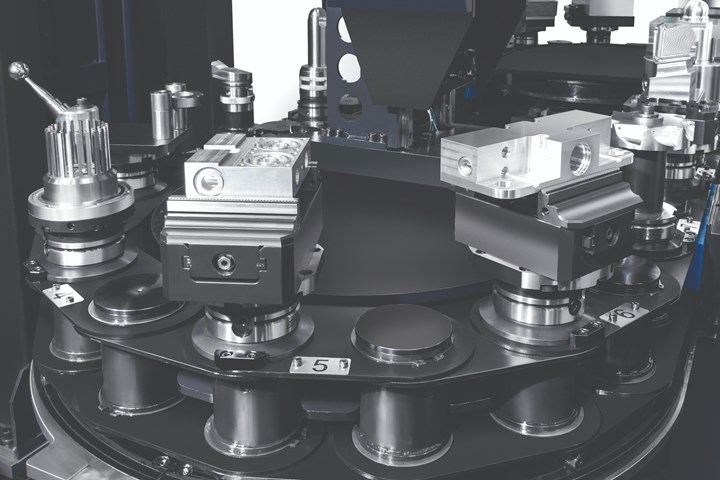

- More efficient inspection processes are needed. Lights-out machining enables shops to get the most value out of their equipment and employees. What’s better than coming to your shop in the morning to find a number of parts machined unattended? However, that often means there are many parts in the queue to be inspected. Part measurement can become an early morning bottleneck that soaks up shopfloor workers’ valuable time. This has shops looking to new measurement technology that can speed and simplify part measurement (vision systems, for example) so workers can get back to other duties.

The Detector series from SPC Innovations features a modular design that is said to offer easy calibration and configuration of various sensors based on a specific part while enabling the system to be installed on other machines.

- More processes are being brought in house. In some respects, “machine shop” is no longer a valid description of a manufacturer with machining capability. Modern production manufacturers are looking to be one-stop shops for their customers. That has them eyeing processes and equipment that can enable them to machine, finish, assemble, package and perhaps even manage inventory for customers.

Hwacheon says it is seeing increased interest in automated solutions for highly complex parts such as those produced on its D2-5AX five-axis machine. This automatic workpiece changer that can be fitted to such a machine is available in eight or 20-station models and can accommodate parts with a maximum diameter of 300 mm and weight of 80 kg.

- Design for manufacturability advice is a value-add. High-volume contract shops tend to have tighter relationships with their customers than job shops. More importantly, they have a tighter relationship with their customers’ engineers, including some who don’t have machining knowledge or in-house machining expertise they can tap for design advice. Instead, these engineers increasingly rely on production machine shops to offer advice for ways to modify new product/part designs to speed and simplify machining. Shops providing this advice early in the new product design/prototyping process often end up winning the production work that will follow.

So, what am I missing here? What other subject matter should we focus on in Production Machining? Shoot me an email. Thanks.

Read Next

Seeing Automated Workpiece Measurement in Real Time

User-friendly inspection software for CNC machining centers was shown at IMTS 2024 monitoring measurements between and after machining while performing SPC based on recorded measurement values.

Read More5 Aspects of PMTS I Appreciate

The three-day edition of the 2025 Precision Machining Technology Show kicks off at the start of April. I’ll be there, and here are some reasons why.

Read MoreDo You Have Single Points of Failure?

Plans need to be in place before a catastrophic event occurs.

Read More

.jpg;maxWidth=300;quality=90)