Horizontal and Vertical Lathes

Horizontal lathes have a main spindle that orients spinning workpieces horizontally as a static tool moves down the length of the workpiece to shape the part. These were the world’s first machine tools. Vertical turret lathes (VTLs) have main spindles that are oriented vertically. VTLs in which the spindle faces upward are often used for large, heavy workpieces as they use gravity to their advantage in clamping parts during turning operations. VTLs in which the main spindle faces downward offer the advantage of using the main spindle as a part pickup device, essentially serving as its own robotic part loader. Both horizontal lathes and VTLs are often available with live-tooling spindles to perform operations such as milling and cross drilling in an attempt to machine parts complete in one setup.

ESSENTIAL READING

VIEW ALLVideo: Why a Production Machine Shop Started a Baseball Bat Company

A 153-year-old manufacturer of precision, metal pins recently started a side business creating custom wooden baseball bats. The reasoning behind establishing this new company is intriguing, as is how it has helped create a stronger bond with the local community.

WatchProgramming Upside Down Lathes

This article shares how advances in programming and sensing technologies have made the use of the inverted vertical tuning center even more productive, efficient and reliable for untended or lightly tended operation.

Read MoreProgramming Self-Loading Vertical Turning Centers

This article looks at some programming considerations for a self-loading VTC to help get the most efficient production from these machine tools.

Read MoreMoving Vertical Turning Up

There is always room for improvement, and transitioning from vertical turning to inverted vertical turning can be one way to improve your shop’s efficiency. The benefits of inverted vertical turning include a smaller machine footprint relative to horizontal turning centers of similar capacity; multitasking capabilities; and maybe the biggest benefit—chips fall away from the spindle into a conveyor in the machine base and out of the workzone.

Read MoreHard Turning with Inverted Vertical Turning Centers

When it comes to the machining of hardened surfaces, hard turning is a particularly efficient solution that, compared with grinding, offers a radical reduction of machining times and investment costs.

Read MoreRepeatability with Heavy-Duty Vertical Turning

Developments in vertical turning technology, such as multitasking functionality, have further increased these machines' relevance.

Read MoreLatest Products

DN Solutions Announces Twin-Spindle, Twin-Turret Horizontal Turning Center

IMTS 2024: DN Solutions introduces a twin spindle, twin-turret horizontal turning center with 4″ bar capacity for increased productivity and simultaneous machining performance.

Read MoreRomi Turning Machines Provide Enhanced Precision

IMTS 2024: Romi features both a custom CNC lathe and a 12-axis horizontal turning center for wear resistance and precision in turning, milling and drilling operations.

Read MoreOkuma Machine Lineup Features Intelligent Manufacturing Technology

IMTS 2024: Okuma’s booth features CNC machine tools, a CNC control, a line of automation systems, intelligent manufacturing technologies, customer services and more.

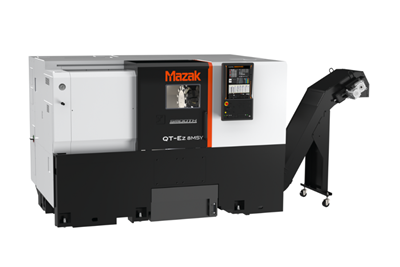

Read MoreMazak Horizontal Turning Center Enables Versatile Machining

The QT-Ez 8MSY horizontal turning machine integrates seamlessly with bar feeders and robots, and accepts many additional options to tailor it to the needs of any shop.

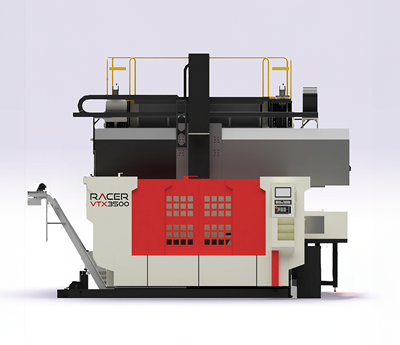

Read MoreRacer Machinery Lathe Enables Full Ram Travel

The VTX machine series features programmatic indexing of the Y-axis, enabling for extended height to accommodate taller parts.

Read MoreCompact Headstock Lathe With High Power Density

This sliding headstock automatic lathe offers simultaneous machining with up to 3 tools — each tool with a variable feed rate.

Read MoreFeatured Posts

When a “Boxy” Part is Machined on a Lathe

South Morgan Technologies has long thrived on its ability to mill prismatic parts on a turning platform. Today, newer technology and techniques enable saying “yes” to that work than ever before.

Read MoreRobotic Automation Options for Vertical Turning Centers

Custom robotic machine tending systems designed for specific high-volume machining applications can yield significant productivity and product flow benefits.

Read MoreHigh-Volume Machine Shop Automates Secondary Ops

An Ohio contract shop added a compact, self-loading CNC lathe to perform unattended secondary ops on a part for a key customer rather than running it on a manually loaded chucker.

WatchBoring Head Enables Sculpture Hardware to Be Machined on a Lathe

When small job shop Ansonia Manufacturing took on a tricky hardware component job for a “live” glass art sculpture, it realized a boring head would be needed to machine the part complete on its live-tool lathe.

Read MoreIn-Machine Probing Possibilities for VTLs

A manufacturer of vertical turning centers uses a “push/pull” optoelectronic probe with custom bracket to enable its machines to perform effective, in-process measurement of shafts and related automotive components.

Read MoreVideo: Why a Production Machine Shop Started a Baseball Bat Company

A 153-year-old manufacturer of precision, metal pins recently started a side business creating custom wooden baseball bats. The reasoning behind establishing this new company is intriguing, as is how it has helped create a stronger bond with the local community.

WatchFAQ: Horizontal & Vertical Lathes

What is a horizontal lathe?

Horizontal lathes have a main spindle that orients spinning workpieces horizontally as a static tool moves down the length of the workpiece to shape the part. These were the world’s first machine tools.

What is a vertical lathe?

Vertical turret lathes (VTLs) have main spindles that are oriented vertically. VTLs in which the spindle faces upward are often used for large, heavy workpieces as they use gravity to their advantage in clamping parts during turning operations.

What does a lathe do?

Lathes are commonly used to reduce the diameter of a workpiece to a specific dimension, producing a smooth surface finish. Basically, the cutting tool approaches the rotating workpiece until it begins peeling away the surface as it moves linearly across the side (if the part is a shaft) or across the face (if the part is drum-shaped).

Source: Buying a Lathe: The Basics

.jpg;maxWidth=300;quality=90)

.jpg;maxWidth=970;quality=90)