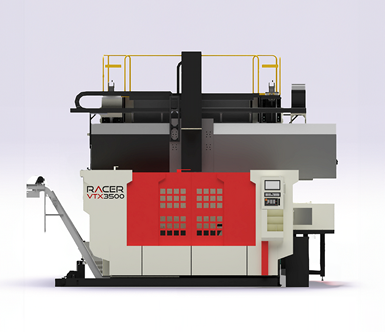

Racer Machinery Lathe Enables Full Ram Travel

The VTX machine series features programmatic indexing of the Y-axis, enabling for extended height to accommodate taller parts.

Racer Machinery International’s VTX machine series of vertical turning lathes feature a cross rail designed for full ram travel. The rail is guided on both ends for higher accuracy and for the ability to hold two tools in each holder, enabling seamless turning of IDs and ODs. Programmatic indexing in the Y-axis enables for extended height, accommodating taller parts with ease.

The VTX series features a rail designed for full-length travel, providing turning of the internal and external diameters of a part. Supported and driven on both ends, it is said to guarantee rigidity and accuracy in machining operations. The frame, engineered using Racer’s patented Phantom Machine Design process, effectively absorbs maximum vibration, enhancing stability and surface finish.

Versatility is a key feature of the VTX series as it accepts tooling for turning, milling or grinding, offering users the flexibility to handle diverse machining tasks with precision. With a 32-station tool changer as standard, mounted off the machine frame, tool changes are quick and efficient, reducing downtime and maximizing productivity.

Related Content

-

Automation Breakthroughs Revolutionize Precision Machining for Complex Parts

Marubeni Citizen-Cincom delivers custom solutions to address some of the biggest challenges in precision machining from handling small parts, to robot integration and unique tooling needs.

-

6 Tips for Training on a Swiss-Type Lathe

There are nuances to training a person to effectively operate a Swiss-type lathe. A shop I visited a while back offers some suggestions.

-

Getting More Production From Swiss Turning Centers

Buying a new CNC Swiss turning center is a substantial investment. For the best return, look closely for capabilities that enable the best utilization of the machine.

.jpg;maxWidth=300;quality=90)

.jpg;maxWidth=300;quality=90)