Gent Machine continues to add equipment such as these Swiss-types as well as rotary transfer machines to machine parts complete. For one part, though, it made more sense to get a CNC lathe to perform secondary ops after partial machining on an Acme screw machine. (Photo credit: Gent Machine)

Equipment-wise, Gent Machine in Cleveland, Ohio, is a mix of the legacy and the new. In fact, a wall in its facility separates the Davenport and Acme screw machines from the CNC department that includes various Marubeni Citizen-Cincom Swiss-types and a Hydromat Epic 45/16 CNC rotary transfer machine. (You’ll also find a rebuilt, hydraulic 32/4-16 Hydromat rotary transfer machine there, too).

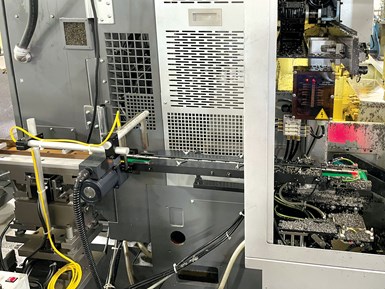

Near the end of 2022, however, a compact, automated, two-axis CNC lathe was installed on the legacy machine side of the building. The reason? The shop felt it made sense to add this machine to perform secondary ops to complete one type of part for a key customer after being partially machined on an Acme.

This part would either have to run across two machines or would require a machine such as CNC multispindle or rotary transfer machine to produce it complete. The shop decided it could drop the part almost complete off of an Acme screw machine then use the automated J-Wave CNC lathe to finish the inner-diameter features on the back side of the part. (Remaining photo credits: PM)

This was one of three paths the shop could have taken to produce the part, one that the customer had previously machined in house. A second would have been having an operator manually load a chucker machine which would require constant attention and a second shift to achieve the throughput required for this million-piece order. A third would be to purchase a CNC multispindle or additional rotary transfer machine, but the shop didn’t feel that level of investment was warranted for this job.

The self-loading CNC lathe seemed to be a cost-effective means to achieve the degree of unattended operation necessary for such a high-volume job.

The compact design of this automated CNC lathe makes it well suited for creating machining cells.

Advancing with Automation

Gent Machine isn’t new to the pages of Production Machining. In a story at gbm.media/gent-521, you can learn about how it recently added new CNC technology after initially relying solely on legacy screw machines.

As I explained in that story, the contract shop was established in 1927. In 2009, brothers Rich and Adam Gent purchased the company from their father, Richard Jr., who assumed ownership in the 1970s. The brothers’ great-grandfather and grandfather, Arthur and Richard Sr., respectively, started the business in South Euclid, Ohio, producing grenade fuses and firing pins.

That story describes how the brothers considered ways to improve machining efficiencies and capabilities while diversifying its customer base to be able to withstand ever-changing business conditions. This included the addition of its CNC Swiss-types and rotary transfer machine.

I recently learned that the shop had added a CNC lathe specifically for secondary op work for a relatively simple part. While that’s not uncommon, the machine’s design and self-loading capability was intriguing so I visited again earlier this year to learn more.

“For years, we had been looking for an automated solution to eliminate hand loading chuckers for secondary work,” Rich says. It seems the shop found a solution in the J-Wave gang-type CNC lathe from Takamaz.

It was Willie Eichele from nearby machine tool distributor and turnkey system provider Motch and Eichele (part of The HEH Group) who put the brothers in touch with representatives from Takamaz to discuss how best a compact and economical J-Wave CNC lathe could be set up to perform the secondary op work automatically.

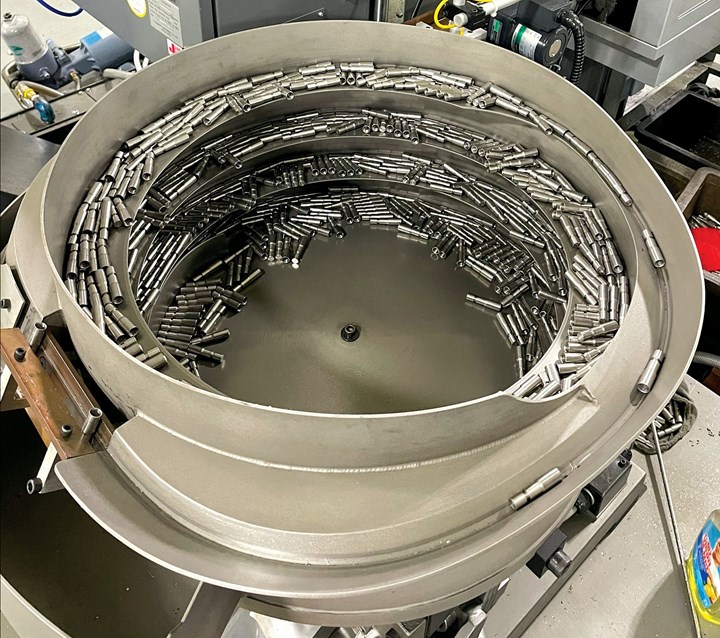

A bowl feeder is used to provide workpieces to the conveyor. This helps extend the potential for unattended machining on the lathe.

The J-Wave the shop purchased late last year has a 4-inch chucking capacity, maximum spindle speed of 4,500 rpm and gang plate with the ability to load as many as five tools. (Only three are required for the current 303 stainless steel part running on that machine to complete the part’s back side inner diameter.)

“We feel it’s a good fit for shops like ours that have screw machines and run high volumes.” — Rich Gent

The lathe was purchased with a part-loading conveyor. So, it would be possible for an operator to frequently load a number of parts on the conveyor. However, this would require a good bit of attention on the operator’s part to keep the conveyor full. To enable much longer stretches of unattended operation, a large bowl feeder was added by Takamaz to continuously feed the conveyor.

The semi-completed parts are loaded into the bowl feeder which vibrates them around the bowl to the proper orientation after which they are delivered to the conveyor. The conveyor moves the parts into position for the machine’s integrated gantry-type loader to grip them and load them into the machine’s collet chuck while unloading a completed part. The loader then moves back to the conveyor and drops the completed part down a chute while then picking up a new part for the next cycle. Sensors near the end of the conveyor where parts are picked detect if the conveyor is empty.

Sensors near the end of the conveyor where parts are picked detect if the conveyor is empty.

Currently, the cycle time to perform the three hole-making operations is 22 seconds. This will likely be reduced as the shop gets to know the machine a little better. Chip management/buildup on tools was an initial challenge that was mitigated in part due to through-tool oil delivery. In addition, some enclosure modifications were made to prevent oil from splashing on the conveyor. “This was not a turnkey project, which admittedly was a risky move on our part,” Rich says. “However, bringing this online ourselves enabled us to better get to know and appreciate the machine and its capabilities.

“We feel it’s a good fit for shops like ours that have screw machines and run high volumes,” he continues. “In our case, we were able to combine a bought-and-paid-for Acme with a cost-efficient CNC lathe to complete the part. In the future, the machine could be set up to perform secondary ops on a different part or be used as a primary machine for relatively simple parts.”

Related Content

In-Machine Probing Possibilities for VTLs

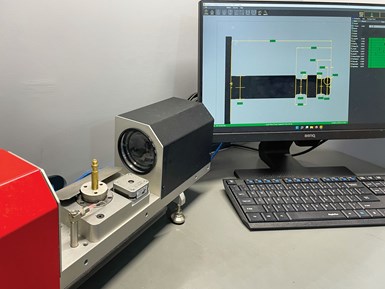

A manufacturer of vertical turning centers uses a “push/pull” optoelectronic probe with custom bracket to enable its machines to perform effective, in-process measurement of shafts and related automotive components.

Read MoreTurret Lathe Features LFV Technology

PMTS 2023: Marubeni Citizen-Cincom offers the Miyano ANX-42SYY fixed headstock-type CNC automatic lathe which has a variety of features that improve machine operating convenience.

Read MoreBoring Head Enables Sculpture Hardware to Be Machined on a Lathe

When small job shop Ansonia Manufacturing took on a tricky hardware component job for a “live” glass art sculpture, it realized a boring head would be needed to machine the part complete on its live-tool lathe.

Read MoreWhen a “Boxy” Part is Machined on a Lathe

South Morgan Technologies has long thrived on its ability to mill prismatic parts on a turning platform. Today, newer technology and techniques enable saying “yes” to that work than ever before.

Read MoreRead Next

5 Aspects of PMTS I Appreciate

The three-day edition of the 2025 Precision Machining Technology Show kicks off at the start of April. I’ll be there, and here are some reasons why.

Read MoreA Tooling Workshop Worth a Visit

Marubeni Citizen-Cincom’s tooling and accessory workshop offers a chance to learn more about ancillary devices that can boost machining efficiency and capability.

Read MoreDo You Have Single Points of Failure?

Plans need to be in place before a catastrophic event occurs.

Read More