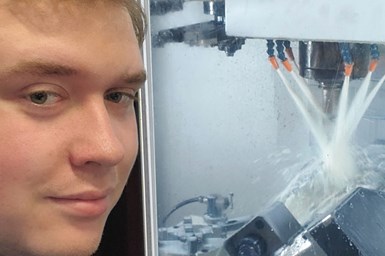

Video: Emerging Leader Alex Cheesman Fixates on Expanding His Machine Shop

Learn about this enthusiastic leader’s journey of opening a new business and his other exciting plans to continue to contribute to manufacturing.

Twenty-one-year-old 2021 Emerging Leader Alex Cheesman is a go-getter. Not only did he earn an associate degree earlier than most, but immediately after that, he opened a subsidiary of his family’s company, which he named Innovative Custom Engineering (ICE). Now he is working toward building his company that is constantly expanding, and he says he does not plan to stop any time soon.

In fact, he has added six more machines since he was named an Emerging Leader, including three CNC grinding machines, two CNC lathes and a CNC mill. This increased capacity has earned ICE (Sussex, Wisconsin) double the workload from its already existing customers.

ICE, which manufactures custom milling tools and components as well as indexable inserts, is a great example of how a shop can optimize automation to the fullest. Because Cheesman has taken advantage of bar feeders and lightly tended machining, he only needed to hire one more person since investing in the new machines.

Cheesman is a third-generation member of his family who is making an impact on the metalworking industry. Since earning his degree in robotics, he has completed self-taught courses in manufacturing engineering. Also,

Cheesman has a robotics degree and is working on two tooling patents.

Photo Credit: ICE Tools

according to Tony Messing, Cheesman’s nominator and senior operations manager at AdvantEdge Cutting Tools, Cheesman is working on two tooling patents.

“His expertise has made a great impact in many of the die and mold shops here in western Michigan,” Messing says. “Alex is a brilliant and enthusiastic young man.”

For more information about Cheesman and his business strategies and advice, as well as other 2021 Emerging Leaders, read Young Leaders Define Their Business Strategies.

Related Content

-

2023 Emerging Leaders Strengthen Their Staffs, Solve Problems

Superb critical thinking, top-notch leadership skills and a passion for building a strong team are a few of the common traits held by this year’s five Production Machining Emerging Leader award winners.

-

Succession Planning: Three 15-Minute Activities to Start Preparing for Tomorrow

Succession planning is planning for the future success of your business.

-

Manufacturing Skills Training: Virginia Martinez and Laiken Carrillo

Roles of Women in Manufacturing Series: A precision machining career starts with skills. Virginia and Laiken share their journey and how they help prepare the next generation.