Don’t Burn the Tool

If a tool gets too hot to hold while grinding, you have already ruined it.

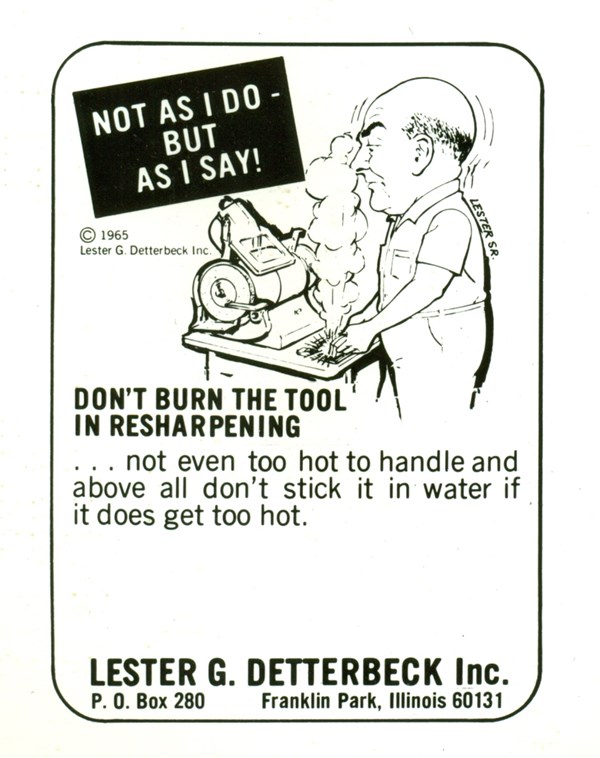

A bit of circa 1965 “Knowledge Retention” from the archives of Lester Detterbeck Enterprises Ltd.

If a tool gets too hot to hold while grinding, you have already ruined it. You knew that, right? By the time the heat gets to your hands and is too hot to hold, you have already lost the temper on the edge being ground. If you then put it in water to cool it down, depending on the material grade, the water quench is likely to help form untempered martensite, a brittle microstructure.

The tool will lose properties and fail in very short order, often with catastrophic consequences. The point of grinding is to take small amounts of removal by abrasion, not to create lots of heat by hogging the material off.

Heat treated tools are actually very sophisticated system involving the interaction of material chemistry, microstructure, mechanical properties (including hardness) and design.

Out of control grinding practices can destroy this system with a single temperature excursion above the tool’s last tempering temperature and formation of untempered martensite by water quenching.

Thanks to John Detterbeck at Lester Detterbeck Enterprises Ltd. for sharing the above cartoon and confirming the failure mode.

This article was originally posted on PMPAspeakingofprecision.com blog.

.jpg;maxWidth=300;quality=90)