WTO High-Speed Spindle for Improved Productivity

PMTS 2023: The CoolSpeed ultra-high-speed spindle line can efficiently turn any machine into an ultra-high-speed machining center, offering plug-and-play, crash-resistant and maintenance-free production.

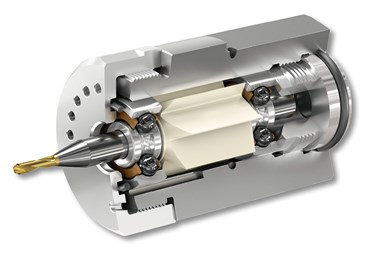

It is said the CoolSpeed spindle can efficiently turn any machine into an ultra-high-speed machining center. Photo Credit: WTO

WTO’s CoolSpeed is an ultra-high-speed spindle line created to help customers improve their productivity by offering spindle speeds up to 80,000 rpm. It is said higher spindle speeds equate to faster cut times and longer tool life when using microtools.

CoolSpeed utilizes turbine technology which is coolant/oil- or air mist-driven with a broad range of operating conditions. The bearings and turbine are easily press-fit onto the cutting tool shank using an assembly device and can support a variety of tool shank sizes.

The company says the spindle offers continuous high precision. The cutting tool shank serves as the spindle shaft with dynamic runout of 4 microns or better. And the bearings can be easily replaced with each cutting tool change.

It is said it can efficiently turn any machine into an ultra-high-speed machining center, such as milling centers, turning centers and Swiss-type lathes. It can also extend the machine spindle lifetime and fits in standard toolholders for automatic tool change. Due to its design, there is no maintenance required.

The spindle can be installed on almost any machine and is through-spindle-coolant (TSP) and automatic tool-change compatible. Setup and installation of the spindle is easy. Users simply install CoolSpeed into a hydraulic chuck or sealed ER collet and measure the rpm with the included pressure gauge provided in the starter set.

Users aren’t limited by their machine’s main spindle speed. Most machines have a live toolholder or main spindle with speeds ranging anywhere from 6,000 to 24,000 rpm. CoolSpeed will help preserve the life of the main spindle and bring the machines spindle speed up to 80,000 rpm which is a much better range for microtools.

Related Content

-

KGT Live Tool Replacements for Swiss Machines

PMTS 2023: It is said the KGT tools are constructed with top-of-the-line gears and high-quality bearings, providing machinists with a high-performance result and a long tool life that are comparable to OEM products.

-

Why Are We Writing About a Shop Making Custom Baseball Bats?

I recently learned about a 153-year-old manufacturer that has produced billions upon billions of precision, metal pins which started another business making one-off wooden baseball bats. (Like I asked it to do for me and you’ll see at this year’s Precision Machining Technology Show). Here I explain why it’s worth the time to read that article.

-

Syncrex Swiss-Styles for Fast Tool Setup, Easy Programming

PMTS 2023: The Mazak Syncrex series comes in four bar capacities, ranging from 20 to 38 mm, and is available in 7-, 8- and 9-axis configurations as well as a 9-axis model with full B-axis contouring.

.jpg;maxWidth=300;quality=90)