10 Smart Steps to Take Toward Recovery

Sponsored ContentWith many manufacturers facing challenges in light of the novel coronavirus pandemic, these 10 steps can help position manufacturers to find success.

Share

It’s safe to say that no manufacturers are having the 2020 they expected and planned for. The pandemic, oil crisis and conflicts new and old have converged to remind us that sometimes our success lies very much beyond our control. In short, we’re in what sports enthusiasts might call a ‘rebuilding year.’

While ‘rebuilding year’ is occasionally used as a tongue-in-cheek excuse for a bad season, its true meaning offers an important reminder to those who want to emerge from the current crisis prepared to thrive. The shock of unexpected adversity can be difficult to overcome. That said, the most successful shops recognize that while the factors causing short-term pain may be beyond our control, they also create unique opportunities and liberate us to pursue actions that will maximize the scope of our long-term success.

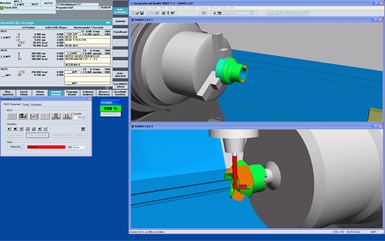

INDEX’s Virtual Machine, which offers a one-to-one digitalization of a shop’s actual machine, allows for highly effective training from anywhere an operator can take their computer.

Whether you’ve already been aggressively planning a comeback or have struggled to decide where to focus your efforts, the following 10 recommendations can help you position your shop for success as we come out of the current downturn.

1: Expand Your Team’s Expertise

When demand is high and there’s a steady stream of work, it can be hard to find time for training. Dry spells provide the perfect opportunity to refresh and expand your team’s knowledge base. Whether you’re obtaining in-person or virtual training from a machine builder or establishing an internal cross-training program, increasing your team’s expertise will yield significant long-term benefits. Note that cross-training between departments is especially valuable in the current environment. As long as the pandemic is ongoing, it has the potential to disrupt your operations. Having a flexible workforce is a huge competitive advantage in these conditions.

2: Find and Hire Talent

It may seem counterintuitive to add to your team when you’re already operating at reduced capacity, but it deserves serious consideration. The challenges we’re facing today are much more short-term than the ongoing skilled labor shortage. Many highly talented people are currently unemployed. If you can afford it, now is a great time to identify and onboard team members who will become the future of your company. This is especially true for shops running older machines with team members possessing a more traditional operator skillset. Those shops will soon need a different class of machinist with a broader range of skills, and now is an ideal time to find them.

3: Audit Your Workflow

If you’re not getting better relative to yourself, you’re getting worse relative to your competition. Despite this, many shops are hesitant to invest the time necessary to identify waste and bottlenecks within their operations. That can be understandable when business is booming, but there’s no excuse for it when work has slowed. Use your current excess labor capacity to have your team map the flow of parts through your facility and develop recommendations to improve it. This can yield permanent boosts to your profit margins.

As an example, one INDEX customer walked the path one of their highest quantity parts took through their facility. This opened their eyes to significant delays, leading them to invest in turning centers that could fully cut parts in a single setup, as opposed to having to pass across four separate machines. They then purchased and installed deburring, cleaning and inspection stations at each machine. Turnaround time for individual lots went from being measured in weeks to days. This type of improvement can be found in most shops, it’s just a matter of taking the time to find them.

Those shops looking to evolve their capabilities to reach new customers would do well to see how Wiscon Products has transformed its operations through new technologies over the past decade.

4: Reorganize Your Workflow

When prioritizing actions to take while things are slow, think about how disruptive something would be when operating near or at full capacity. For most shops, moving machines around to optimize the flow of parts through a facility would be near the top of that list. If you know (or discover through the previously recommended audit) that your equipment would be more effective with a different layout, now is the time to shake things up in the name of future efficiency.

5: Optimize Your Machines

Preventive and corrective maintenance can dramatically revitalize your machines. Beyond that, there is nearly always a better way to produce a part, whether through refining the cutting process, updating cutting tools, adding automation, etc. In normal circumstances, time is the primary barrier to getting the most out of your machines and improving your processes. When you have a surplus of time, you should be investing as much of it as possible in getting better.

Many machine builders, including INDEX, have invested in online tools that allow their teams to work virtually with yours to optimize your processes.

6: Understanding Your Future Requirements

Even amidst the current uncertainty, there are predictions you can make with a high degree of confidence. The skilled labor shortage will continue. Price pressure will continue to intensify. An increasing use of data collection and analysis will put companies at the tail end of this trend at a disadvantage. Take what you know of the market and your current operations, and think through several of the most likely scenarios for the next 3 – 5 years. Does your current technology keep you where you need to be in terms of growth and profit? If not, identify the areas where you need to evolve to reach your envisioned potential.

7: Invest in Your Evolution

Have you been putting off replacing a machine or incorporating a new technology to avoid disrupting your production? Or maybe you’ve been considering automation, but held off for similar reasons? Or, per the previous item on this list, perhaps you took stock of your operations and realize you need a more productive solution? Now is the perfect time to invest in your future success. Interest rates are low and a variety of creative financing arrangements are available. The disruption to your operations has far less impact when operating at a lower capacity. Likewise, you have more time available to learn and truly optimize new technology so that it will be at peak effectiveness when things start to pick up.

8: Anticipate Reshoring

The pandemic exposed significant drawbacks to a global supply chain. While international trade will obviously continue, experts are nearly unanimous in the expectation that many industries will demand substantial production capacity closer to home. Thomas’s monthly survey of American manufacturers currently reveals a majority of 64% expecting to reshore at least some work over the next year. If you’re looking to grow as opposed just get back to pre-pandemic levels, now is the time to be talking to current and potential customers about their reshoring plans. Then expand your capacity and capabilities to win that work.

9: Establish Contingency Plans

You’ve invested in building specific capabilities for your current part mix. Thinking through how those capabilities can be applied to other segments can uncover growth opportunities.

The pandemic has been a stark reminder of just how quickly an unforeseen event can cause far-reaching havoc. Planning for the unexpected provides a potential competitive advantage both in the short and long term. At a minimum, you should invest time thinking through responses to events that are easy to envision. For example, what will you do if one of your largest customers is forced to temporarily close a facility? Or if your shop has one or more cases of COVID-19? Beyond that, consider the market segments you currently serve or could serve. If automotive stalls out while aerospace takes off, how will you react? Developing simple, actionable plans for these types of scenarios allows you to move quickly and confidently compared to competitors who haven’t pre-formulated a response.

10: Engage Your Technology Suppliers

Nobody knows your applications better than your team, but nobody knows your machines better than the companies that built them. In the current market conditions, nearly every aspect of manufacturing has excess capacity, including your technology providers. Now is the perfect time to engage with them and put their expertise to work towards your future success. They can boost your effectiveness at taking nearly any of the other actions on this list, as well as help you discover even more ways to build and maintain a competitive advantage.

Companies like INDEX stand ready to support you through this difficult time. From training to applications support and process optimization, from preventive maintenance to conducting time studies and cost justifications or evaluating new technology, they can help you weather this crisis and succeed on the other side.