CNC Programming Software Increases Precision and Speed

Programming by hand was once a reality for IM Torneria (Bologna, Italy). However, when projects with complicated components became the norm for the shop, it was obvious to the company that CAM was needed.

Programming by hand was once a reality for IM Torneria (Bologna, Italy). However, when projects with complicated components became the norm for the shop, it was obvious to the company that CAM was needed.

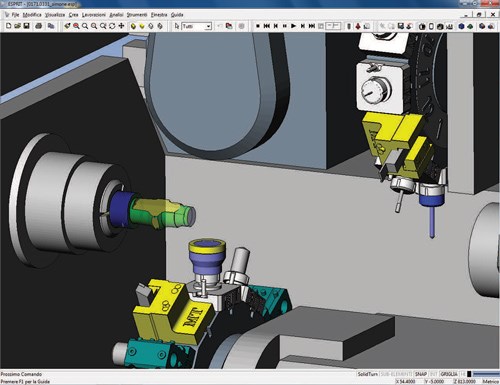

In 2003, IM Torneria increased its production capacity by opening a new facility, considerably expanding production capacity. This is when the company decided that it was no longer feasible to continue programming by hand. The most financially rewarding projects were inevitably those involving the most complicated components, and the current programming methods were not up to the task. After reviewing at least four other CAM software programs, the company acquired Esprit CAM software from DP Technology to meet the programming requirements for a Citizen M32 sliding-head lathe.

“When we were reviewing Esprit, I was impressed by the ease with which I was able to create automatic cycles, including the use of macros using Microsoft Visual Basic,” says Andrea Monduzzi, IM Torneria’s production manager. “Esprit saves time when creating machine programs for our Citizen M32, offering a programming environment similar to the machine controllers. With Esprit, we can successfully program complicated parts on our M32. Parts that would have been difficult to produce before are easily managed now.” The increased efficiency has also extended the tool life.

“Esprit is also used to program a Nakamura-Tome Super NTJ multitasking CNC multi-axis turning center,” Mr. Monduzzi says. This multitasking machine is used by IM Torneria to produce a component for a power-assisted pruning system.

IM Torneria has been operating in the manufacturing and contract machining sector since 1981. It produces automotive and transmission components, industrial pipes and fittings and pneumatic pruning systems for the arboriculture industry.

IM Torneria’s typical workflow, after receiving the customer’s CAD file, involves programming the CNC machine with the programming software and managing the workflow for tooling and the machine tools used in production. “Esprit has an open architecture, so I can use macros to customize the software to fully automate many aspects of the programming process,” Mr. Monduzzi says.

As hoped, the company’s improved capabilities have meant increased business. “Word of mouth has been spreading, and more companies now rely on us to produce their complex parts,” Mr. Monduzzi says. “Today, we work with international companies, including Campagnola (pneumatic and electronic systems for pruning vineyards and olive groves), WAY (automation systems for windows, skylights, shutters, blinds) and Marposs (measurement systems).”

It has paid IM Torneria to switch from programming by hand to CNC programming software from Esprit. With an increase of precision and speed, the company is now more competitive with other companies.

— Marubeni Citizen-Cincom Inc.

Related Content

-

Verisurf Probing Suite Provides Flexibility in Quality Inspection

Verisurf’s Machine Tool Probing (MTP) suite is an in-process automated inspection solution for CNC machine tools, offering inspection and reporting capabilities.

-

Integrated CAD/CAM Software for Maximum Efficiency

PMTS 2023: This software solution is said to enable users to take advanced mill-turn and Swiss-type machining to new levels of speed, efficiency and simplified programming.

-

Tezmaksan CAM Software Streamlines Robotics Programming

RoboCAM is designed to eliminate the complexities of robotics programming, making it accessible to operators of all skill levels.

.jpg;maxWidth=300;quality=90)