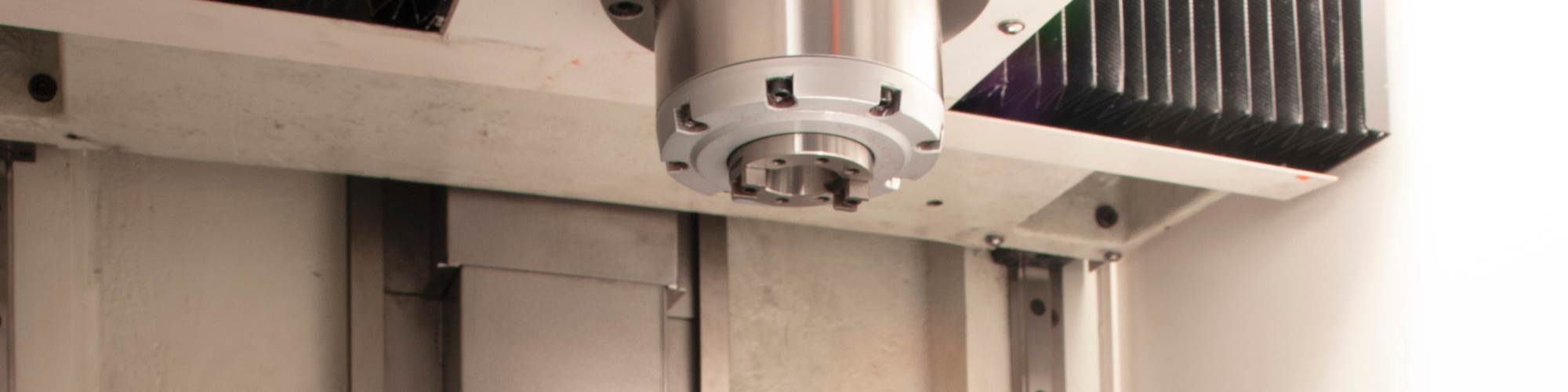

This compact CNC mill can be used for secondary operations and/or as a standalone production machine. It can be easily redeployed to different areas of a shop, if necessary. Photo credits: Trak Machine Tools

For all the advances in multitasking turning technology over the years — live tooling, Y-axis motion, B-axis spindles and so on — sometimes it’s either necessary or simply makes more sense to use a second-op machine to perform requisite milling or drilling work.

If floor space allows, a small vertical machining center (VMC) might do the trick. In fact, Trak Machine Tools/Southwestern Industries Inc., offers its compact VMC2 that can be used for secondary operations and/or as a standalone production mill. This machine can also be easily redeployed to different areas of a shop, if necessary.

The VMC2 shares a number of design elements with its predecessor, the 2OP. One is a small footprint. The VMC2 measures 30.5″ × 52″ while offering a XYZ travels of 14″ × 12″ × 17″ and an enclosure door that opens vertically so the machine can be located near another one, making it convenient for an operator to tend both.

Its bridge construction has a short horizontal head projection and direct-drive spindle. The minimal head projection is said to significantly reduce the thermal expansion effects on the machine’s Y-axis, especially when comparing parts that are run on a “cold” machine in the morning versus “warm” machine later that day.

The machine’s standard eight-station automatic tool changer for BT30 toolholders eliminates the need for manual tool changes, while an integral Jergens Ball Lock fixturing system (consisting of a subplate, fixture plate and shanks) facilitates quick changeovers. With this system, the shanks are inserted through liners in the fixture plate and into receiver bushings in the subplate attached to the machine table. Inside each shank are three balls that expand into a tapered groove in the receiver bushing with just a couple turns of a set screw to provide the holding force between the fixture plate and subplate, and achieve positioning repeatability of ±0.0005 inch.

The machine’s control offers a 15.6-inch touchscreen and conversational programming capability from more than 25 canned machining cycles. An optional adaptive toolpath function is also available.

Perhaps the biggest change from the previous model is the addition of a Prototrak RMX control that is also used on the company’s line of larger bed mills and toolroom machining centers. The RMX offers a 15.6-inch touchscreen and conversational programming capability from more than 25 canned machining cycles. An optional adaptive tool-path function works with defaults users define to maintain a consistent load on the cutter, while using all or most of the available tool cutting length. The results can be better surface finishes and faster cycle times compared to traditional tool paths.

The control software also features single-touch window flyouts to access windows such as tool table, calculator, math help, defaults and options. The options window enables changes to be made to an existing part program that an operator might not want to remain in the original program. It is also possible to zoom, pan or rotate drawings and 3D models as one might do with a tablet or smart phone.

The VMC2 offers air blast or coolant delivery and can be switched between production and toolroom modes. In production mode, the machine features a rapid traverse rate of 600 ipm and maximum spindle speed of 10,000 rpm, an interlocked door and automatic tool changing functionality. In toolroom mode, the rapid traverse rate is 400 ipm, maximum spindle speed is 5,000 rpm, there is no automatic tool changing capability and it can operate with the enclosure door open or closed.

An MTConnect data exchange protocol option enables users to network the VMC2 through either an Ethernet connection or a USB Wi-Fi adapter. In addition, the VMC2 also offers an optional single-phase option for 208-volt power supplies. That said, running the machine on single-phase power reduces the spindle’s 3-hp rating by about 40% compared to 3-phase, 208-volt power.

A quick-change fixturing system helps speed setups for new jobs.

Although designed to be a production machine, it can be redeployed throughout a shop as needed to create “cells on the fly.” In fact, a narrow-fork pallet jack can be purchased with each machine as an option so the user can move the machine around the shop as required. That’s how East Branch Engineering, a shop in New Milford, Connecticut, originally used its 2OP mill, the model that precedes the VMC2, as I detailed in a story a few years ago.

In reconnecting with Chris Guidotti, the shop’s vice president of operations, he says the shop does still move it to create machining cells in which one person tends it and another machine. However, Guidotti says East Branch does not move the machine around much anymore. It is typically positioned centrally between one of the shop’s 5-axis machining centers and different VMCs so the mill can support both types of machines without shutting down and moving it so often.

This machine can be easily redeployed to different areas of a shop, if necessary.

The mill supports the 5-axis machine roughly 75% of the time, often creating add or remove fixture features such as dovetails. The rest of the time it is used to support the VMCs with secondary operations or to machine parts complete.

That said, he notes that East Branch did take advantage of the mill’s easy repositioning at start of the shop’s COVID-19 adjustments last year. The shop initially considered splitting work shifts to enable greater employee distancing. While it did adjust work schedules to a degree, it also moved the mill 180 degrees from its usual position to add physical separation between employees. This lessened the impact of altered work schedules.

Related Content

The Control’s Role in Machining Complex Parts

This company that produces medical implants finds value in the CNC for its turn-mill equipment that helps speed setups and simplify programming when producing intricate parts complete.

Read MorePrecision Machining Technology Review: September 2024

Production Machining’s September 2024 technology showcase includes some of the latest technology from Expand Machinery, Paperless Parts, Monaghan Tooling Group, Walter USA and more.

Read MoreThe Value of CAD/CAM and Cutting Tool Manufacturers Working Together

Overall machining efficiency can be increased when software and tooling companies combine to tackle machining challenges.

Read MoreA Small CNC Machine Shop’s Journey to CMMC

Achieving Cybersecurity Maturity Model Certification (CMMC) — soon to be required to do work for the U.S. government — takes time and money. This 10-person shop takes us through some of the challenges it has faced and lessons it has learned on its CMMC voyage.

Read MoreRead Next

Speed Matters in Microtooling Applications

A variety of tooling spindle options brings micromachining work within reach for shops looking to expand their capabilities.

Read MorePrecision Machining Technology Moving Shops Forward

New equipment and software continue to be developed to support the needs of production machine shops like yours. Here’s a sample of technology now on the market that can help you grow your operation and become more efficient.

Read MoreHuman-Like Robot Automates Secondary Machining Operations

Two seven-axis robots enable two second-op mills to run lights out eight hours in the evenings to win 64 hours of unattended machining time per week for this Ventura, California, shop.

Read More

.jpg;maxWidth=300;quality=90)