Speed Matters in Microtooling Applications

A variety of tooling spindle options brings micromachining work within reach for shops looking to expand their capabilities.

Smaller. Faster. Accurate. The demand for micromanufacturing is increasing worldwide, driven largely by the requirement for smaller products, tools and lead times. Industries such as medical, aerospace and even automotive are using smaller round tools. Virtually every major carbide round tool manufacturer stocks standard products as small as 0.003” diameter.

As the demand for these tools has grown, press coverage, advertising and demonstrations of these remarkably engineered and manufactured products have become widespread. What is oftentimes overlooked, though, is how to apply these tools properly. While the features and benefits of microtools are clearly explained, the running parameters are almost always omitted.

Ultraprecision, high-speed HES810 spindles allow the use of existing equipment for a much larger variety of operations. They are designed to enable conventional milling machines and machining centers to do high-speed machining, small diameter drilling and milling with extremely good surface finishes.

Many of these tools require speeds greater than 15,000 rpm. In general, the smaller the tool, the faster it must rotate to be effective, maximize tool life, improve surface finish and increase productivity. In short, speed matters. This prerequisite presents a problem for many machine shops that often are limited to only 8,000 or 10,000 rpm with their standard mill or Swiss-type machine. Running microtools at reduced speeds actually slows down processes, often creates the need for additional deburring operations and renders the cutting tool virtually ineffective. Yes, there are machines that offer higher-speed spindles, but these are costly and, thus, out of reach for a great many shops. But other options are available that may be surprisingly affordable.

When considering high-speed options, many people generally first think of the traditional gear-driven speeder. These tools are great in short spurts, serving the market well when applied properly. Speeders adapt easily to a mill and are virtually plug-and-play. Tools such as these are good for small diameter applications that require only a small amount of work. However, depending on the model of machine tool in which they are applied, the gear-driven nature of this product could create issues with heat, thermal expansion, excessive vibration and runout. In other words, accuracy is sacrificed when working with gear-driven speeders and microtools. These speeders also require the rotation of the machine tool spindle. As a result, maxing out the machine tool spindle also becomes a concern, as this can greatly reduce the machine’s spindle life. Tool changeability can also be a problem due to their excessive weight, particularly with a 40- or 50-taper machine.

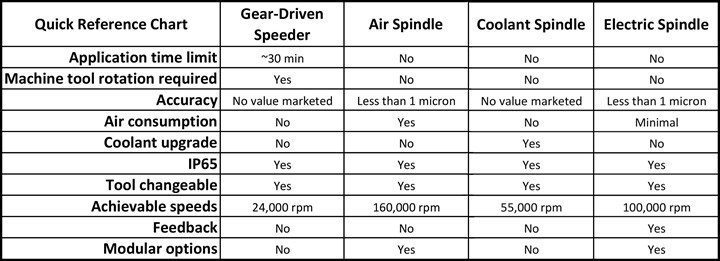

Here's a comparison of features for different high-speed tooling spindle options.

Contemporary air-driven spindles have been on the market for more than 20 years. Using turbine blades and air pressure, speeds can be achieved greater than 160,000 rpm. Because these spindles use pressurized air, which is cool by nature, thermal expansion is not an issue. Newer models in the marketplace even allow for governed speed air motors. This option does not require the use of the machine’s main spindle, which helps to prolong spindle life. However, because air motors require massive quantities of air to drive them, their utilization is indirectly a more expensive option — compressor operational cost by CFM is very expensive and inefficient. Because air spindles are driven by air in an “on/off” environment, speeds will drop when tools are engaged in a workpiece. Also, the speed rating provided for an air spindle is the maximum achievable speed, so speeds are not 100% guaranteed. If there is not enough air pressure, the listed speed may never be achieved. Lastly, like the gear-driven speeder, feedback relating to the performance of the spindle and tool engagement is not available.

Coolant-driven spindles are gaining traction in the marketplace in recent years due to the growth in microtools and marketing campaigns. Similar to the air spindle, coolant-driven spindles preserve the life of the machine spindle. Models are marketed to achieve speeds as high as 55,000 rpm, and some even have a display to show how fast the spindle is spinning. This design provides effective utilization of coolant, as coolant lubricates and promotes tool life as well as finish. The flip side of this spindle option is the requirement to closely maintain coolant quality and filtration. Plus, some brands require upgrading the system to achieve the correct pressure. Similar to an air motor, this system has no feedback to the machine controller that the tool is rotating.

Another, lesser known option, is a high-speed electric spindle. Some spindles of this type in the market can achieve speeds as high as 100,000 rpm. What is nice about these types of spindles is that the speed of the spindle can be controlled in increments of 1,000 rpm. Some brands have a closed-loop system that will always adjust to maintain desired rpm while the motor and spindle are under load. This feature helps to ensure that cutting tool capabilities are maximized. An electrical interface also allows for feedback to and from the CNCs in which they are used. These spindles do not require rotation from the machine tool spindle, do not require upgraded coolant and will not consume as much air as an air-driven spindle. Electric spindles do require a cord, which may require manual intervention when it comes to tool changing in a mill.

The key takeaway is that speed matters. Increasing speed increases productivity, tool life and profitability. Using proper high speeds with microtools reduces perishable tool consumption, could reduce secondary operations and offers more flexibility to the shop. When you have an opportunity to bid on a job that requires microtools, you should not be intimidated nor pass on that bid. The number of options for spinning small diameter round tools makes this type of work more affordable than many people realize. The investment to adapt it to existing machine tools can easily pay for itself with regular use.

NSK America Corporation | 800-585-4675 | nskamericacorp.com

About the Author

Mike Gabris

Mike Gabris is the industrial sales manager at NSK America Corp., which provides application support, sales and repair service for all Nakanishi spindles, high-speed motors and microgrinders for the western hemisphere.

Related Content

Automation Breakthroughs Revolutionize Precision Machining for Complex Parts

Marubeni Citizen-Cincom delivers custom solutions to address some of the biggest challenges in precision machining from handling small parts, to robot integration and unique tooling needs.

Read MoreLyndex-Nikken Collet Chuck Increases Gripping Force

SK collet chucks enables for access to tight spaces and provides better clearance, making it ideal for machining complex parts.

Read MoreCoolant-Through System, Toolholders for Improved Efficiencies

Eastec 2023: The reCool retrofittable reCool coolant-through system converts existing flood-cooled driven tools on turning machines to through-tool, coolant-capable in as little as two minutes, while the powRgrip high-precision toolholding system is said to generate extremely high clamping forces equal to or higher than shrink-fit holders.

Read MoreZoller Event Shines Lights on Shopfloor Connectivity

The company’s open house event highlighted smart manufacturing solutions from CAM to part.

Read MoreRead Next

Keeping Watch on Small Parts

From watch parts to exotic medical applications, this shop takes on the world of micromachining.

Read MoreFaster RPMs Produce Faster Turnaround

When running a metalworking shop, it’s common to have to adjust machining processes to accommodate customers’ demands.

Read MoreDo You Have Single Points of Failure?

Plans need to be in place before a catastrophic event occurs.

Read More