Craftsman Cribsheet No. 100: Built Up Edge — What It Is and What To Do

Because Built Up Edge changes the effective geometry of the tool, it can have either positive or negative effects.

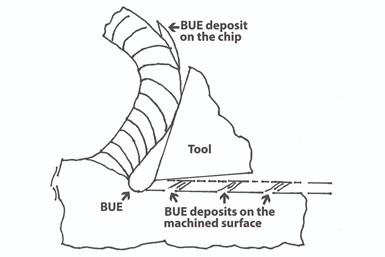

Built Up Edge (BUE) is the accumulation of workpiece material onto the rake face of the tool. This material welds under pressure and is separate from the chip. Schools teach that this is because the first material to contact the tool work-hardens, and hardness tests confirm this. Because BUE changes the effective geometry of the tool, it can have either positive or negative effects.

Positive Effects

- Less tool wear

- Lower power requirements

- Less contact of the workpiece with the tool (It contacts the BUE instead)

- Better surface finish and improved process capability

Built Up Edge (BUE) is the accumulation of workpiece material onto the rake face of the tool.

These effects are only beneficial if the BUE is thin and stable. Machining additives such as sulfur combine with manganese to form manganese sulfides. Manganese sulfide helps to control BUE because of its anti-weld properties. On resulfurized steels, BUE is usually stable and not a problem.

Negative Effects

- Poor tool life

- Poor and variable surface finish (As the BUE sloughs off the tool, it can weld to the workpiece)

- Loss of statistical capability on dimensional control

- Loss of uptime trying to troubleshoot the process

BUE is more likely on alloys that work harden. In order to get BUE under control, the steps that you take depend on the tool material.

For Carbide

- Decrease the feed. (Pressure welding usually is the culprit)

- Increase the speed

- Increase the rake angle or “hook”

- Get a better metalworking fluid (this includes getting the fines out of your existing MWF!)

- Get a different coating

For High Speed Steel (HSS)

- Reduce speed

If the tool is High Speed Steel (HSS), you may think you are in “oppositeland” when you discover that slowing down the speed reduces the buildup. On HSS, as speed (heat increases) so does the tendency to form BUE.

Related Content

-

Craftsman Cribsheet No. 126: AISI System of Identification

Source: PMPA Prior to the Society of Automotive Engineers taking responsibility for Steel Grade nomenclature in the United States (1995), the American Iron and Steel Institute determined U.S. standard steel grades in collaboration with SAE.

-

Cold-Drawn Steel Barstock: How It Is Manufactured, Benefits to Your Shop

Understanding the benefits provided by cold-drawn steel barstock can help you optimize the work you quote by maximizing benefits to your manufacturing process and customer.

-

Manufacturing Skills Training: Virginia Martinez and Laiken Carrillo

Roles of Women in Manufacturing Series: A precision machining career starts with skills. Virginia and Laiken share their journey and how they help prepare the next generation.

.jpg;maxWidth=300;quality=90)