This is what a modern machining operation looks like. Roush Yates Manufacturing Solutions, which has traditionally offered tours to its facility to show off its capabilities, now offers a virtual way to see the advanced technology it has under roof. (All photos courtesy of Roush Yates Engines.)

One of my duties at my previous gig with sister publication Modern Machine Shop was serving as the technical director of its Top Shops benchmarking program (now in its 10th year). The core of this program is a survey that reveals how leading U.S. machine shops (a.k.a. “Top Shops”) stand apart from others not only in terms of the practices they carry out on the shop floor, but also in the front office.

For example, per the latter, the annual survey has consistently asked about shops’ marketing efforts. And, consistently, a higher percentage of leading shops compared to less successful operations say they hold open houses as a way to demonstrate their capabilities to customers as well as promote themselves as a viable career option to potential new hires. This is often above and beyond just opening their doors on Manufacturing Day, which is held each year in early October.

That said, COVID-19 has caused many shops to drastically limit or even prohibit visitors from entering their facilities. But, what about offering virtual tours online?

Prerecorded video uploaded to YouTube is one way to go for this. It can be promoted on a shop’s website or blog as well as via social media. Another way, one used by Mooresville, North Carolina’s Roush Yates Manufacturing Solutions (a division of Roush Yates Engines), is a self-guided, virtual tour that enables people to “walk through” an area of its shop to see and learn more about the technology that piques their interests. (An example of which is shown in the video below.)

Paul Van Metre, founder of ProShop ERP, a Roush Yates Engines technical partner, tipped me off to this. The tour enables one to pick and choose which areas of the machine shop to visit and learn about the technology used there, such as machine tools, cutting tools, workholding devices, coolant, CAD/CAM software, shop management software and metrology equipment.

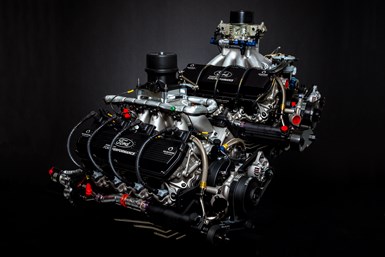

Here are examples of Roush Yates Engines’ carbureted and fuel-injected Ford racing engines.

The surnames Roush and Yates are familiar to automotive racing fans. Jack Roush and Robert Yates were once bitter NASCAR rivals on the track. But, besides having highly competitive spirits, they also, early on, were the only two Ford NASCAR engine builders with race teams. One camp had its own engine design and manufacturing capability and the other had its as well.

Todd English, vice president — strategic partnerships and marketing for Roush Yates Engines, says the two found common ground in 2003. Rather than fighting for the same sponsorship dollars and keeping their Ford engine design and CNC machining knowledge in separate silos, Roush Yates Engines was created to pool their talents as it became the sole provider of racing engines for Ford-sponsored NASCAR teams as well as some road-racing teams.

Having in-house machining capability was advantageous in a few ways. For example, newly designed parts could be manufactured faster and more consistently than outsourcing. Plus, it helped protect the company’s intellectual property.

Roush Yates Manufacturing Solutions features an 88,000-square-foot facility filled with a wealth of machining equipment set up to serve a variety of industries.

By 2014, Roush Yates Engines was machining 40% of its engines’ internal components in house. The company recognized, though, that the same proven machining technology and processes could be applied to the production of similarly complex parts in industries such as aerospace, defense, industrial and medical. Roush Yates Manufacturing Solutions was created to serve those other industries, and now resides in an 88,000-square-foot plant in Mooresville. Today, this facility includes VMC, HMC, 5-axis, turn-mill, Swiss-type and waterjet machines as well as equipment for secondary operations such as laser marking/etching.

Not surprisingly, the company faces the same skills gap challenge as other shops. It met this challenge head-on by initially developing its own CNC machining curriculum that was subsequently acquired by Universal Technical Institute, which has a location close by. Roush Yates Engines continues to work with the institute to refine and update this curriculum, and the institute has become a great resource for new shopfloor talent not only for its shop but for others as well.

And, also like other shops, it often encounters the preconceived notion from students and parents alike that manufacturing operations are dirty and unsafe, providing no real pathway to a successful career, English says. A quick look at the photo of its facility above shows that clearly isn’t the case.

As a result, the shop frequently hosted open houses to enable the community to see what today’s modern machine shops look like and to learn about the career opportunities available to them. English says these tours also enabled the shop to show that working there goes way beyond standing at a machine all day.

Of course, COVID-19 brought a halt to those in-person visits in March. That’s when Roush Yates Manufacturing Solutions considered ways to present its operation online beyond the existing content on its website. The result is a self-guided, virtual tour created with software similar to that used by real estate agencies to present virtual home tours.

Roush Yates Manufacturing Solutions’ machining capabilities include Swiss-type turning.

It functions similarly to Google Street View. In this case, though, viewers are able to maneuver to various stations and click to see video and learn more about the technology highlighted there, such as those I mentioned above. Those snippets are provided by the shop’s various technology partners, and can be updated as new equipment or processes are developed. English says the local Mooresville Graded school district (which has recently added CNC equipment in its middle school and high school and has the support of many of Roush Yates Engines’ technical partners) is excited about the virtual tour because it can be used to promote machining as part of PTA presentations and in other ways. And, the virtual tour now gives Roush Yates Manufacturing Solutions the ability to present itself (and machining in general) to a global audience.

I can envision other shops adopting this type of virtual tour, not only to help promote manufacturing during the current pandemic but beyond. Although it’s unsure when shops like Roush Yates Manufacturing Solutions will be able to host hundreds of visitors like it once did, its virtual tour offers a digital glimpse of how high-tech modern manufacturing is these days.

Read Next

A Tooling Workshop Worth a Visit

Marubeni Citizen-Cincom’s tooling and accessory workshop offers a chance to learn more about ancillary devices that can boost machining efficiency and capability.

Read More5 Aspects of PMTS I Appreciate

The three-day edition of the 2025 Precision Machining Technology Show kicks off at the start of April. I’ll be there, and here are some reasons why.

Read MoreDo You Have Single Points of Failure?

Plans need to be in place before a catastrophic event occurs.

Read More

.png;maxWidth=300;quality=90)

.png;maxWidth=970;quality=90)