Five-Spindle Lathe Expands CNC Multi Line

Introduced at IMTS 2016, the Penta five-spindle lathe adds a CNC alternative to ZPS America’s line of six- and eight-spindle lathes.

Alfred P. Sloan, long-time president, chairman and CEO of General Motors, once said there is one GM auto brand for “every purse and purpose.” With the introduction of its new Penta 518 machine, ZPS America seems to be following that philosophy in the multi-spindle machine tool market.

As the name implies, the Penta is a five-spindle lathe and complements the company’s line of CNC six- and eight-spindle machines. Introduced at last fall’s IMTS 2016, the machine is being marketed as an “island machine concept,” which means it is bought as a package that includes the machine, oil treatment system, chiller chip conveyor and bar feeder. The “island” concept creates a single-source supplier contact for all of these components.

The bar loader included in the package is a custom loader that holds five, 12-foot-long bars that are 19 mm in diameter. Pietro Cucchi, now known as Cucchi BLT, manufactured the bar feeder. The company has been part of ZPS’s parent company, Tajmac, since 2013.

Last November, we sat down with industry veteran and ZPS America’s managing partner, Olaf Tessarzyk, to dig into the details of the new machine.

The Concept

We asked Mr. Tessarzyk, “Why five spindles and why now?”

The domestic multi-spindle market is basically of two minds. The debate centers on the need for flexibility to handle low-volume, high-mix workpieces versus the more traditional, dedicated setups for long job runs.

The former issue of flexibility and ease of change-over is where the CNC multi-spindle has gained a strong market foothold, mostly because the performance of these machines reflects the reality of the market. The latter, long run, “set it and forget it” jobs are increasingly difficult to find. Moreover, the traditional operational skills needed for these lathes are also increasingly hard to find.

Machine builders have responded to this changing environment with a variety of engineering solutions that substitute CNC servo-controlled actuation for mechanical, cam-actuated cross and end slides. Some are hybrids, using both systems. Most of these systems are found on six- and eight-spindle lathes.

According to Mr. Tessarzyk, “We knew ZPS had good coverage of the large-diameter CNC multi-spindle lathes with our six- and eight-spindle machines. The company’s 80-mm eight-spindle is the largest capacity CNC multi-spindle lathe available. The mid-range size is well covered by the six-spindle models. We wanted to begin serving the 20-mm diameter and smaller part market, and at an acceptable price point. That led us to look at a five-spindle concept.”

The viability of the five-spindle lathe design that can produce 20 mm and smaller parts has been successfully proven for more than a century. ZPS, through its parent company, Tajmac, has a history of distributing this design in Europe and leaned heavily on its successful design elements in the concept for the Penta.

The bent shank tapping attachment is an example of one of these successful design elements. “After the cut-off, the pick-off spindle moves backward with the clamped part over a tapping tool, which, once engaged, pulls the part through the back and over the bent shank outside the machine, like pearls on a bracelet. It’s not a new concept, but when it is properly applied on a five-spindle lathe, it is genius,” Mr. Tessarzyk says. “In effect, the bent shank tapping attachment allows an extra operation to be performed with no increase in cycle time and without the need or expense of an extra spindle for parts 20 mm and smaller.”

Spindle Speed Control Choices

All of ZPS America’s CNC multi-spindles are available with independently programmable spindles. Penta offers two variations of its multi-spindle configuration.

On its TM model, all five spindles run at the same programmed speed driven by a single servomotor. It is an 11-kW drive capable of 8,000 rpm. This configuration is more like a traditional multi-spindle, which requires a spindle rotational speed compromise, because the speed of each spindle cannot be optimized for the machining operation being performed.

“There are some operational sacrifices that the synchronous drive system requires,” Mr. Tessarzyk says. “There cannot be cross drilling because the spindle cannot be stopped. Constant surface speed is not required because the metal removal rate on these small parts is so low. Basically, this machine is designed to process simple parts very quickly.”

For more complex parts, the Penta model TMZ is available. It uses five independently programmable servodrives, each rated 5.5 kW and capable of 8,000 rpm.

The CNC multi-spindle configuration presents a problem with trying to drive each spindle independently at a programmed rotational speed. The advantage is that each spindle rotates at the optimal speed for the operation being performed. The trick is how to get power to the spindles while allowing the spindle drum to rotate.

Most builders mount the spindle drive units in the spindle drum and couple them directly to each individual spindle. Basically, two methods are used that enable the direct drives to get around the power connection issue.

One method requires the spindle drum to reverse itself after one rotation to allow the power lines connected to the direct-drive spindles to unwind themselves. The rewind is fast, but it adds to the cycle time.

Using a contact ring is another method of powering drum-mounted direct spindle drive motors. Power is carried through the ring, which is contacted by brushes on the drive motors. This system eliminates the need for rewinding and allows the drum to rotate unidirectionally.

“Both of these methods require active thermal compensation,” Mr. Tessarzyk says, “because the heat generated by the drive motors can affect the thermal stability of the drum, which is critical to the machine tool accuracy.”

Finding a Niche

Key to the development of the Penta TM and TMZ was input from ZPS customers. Some high volumes of relatively simple parts have few features and require high speed. “That’s the niche for the TM,” Mr. Tessaryzk says. “It has all of the capabilities of the TMZ with the exception of independent spindles, including standard VDI tooling packages, XYZ compound cross slides, backworking and bent shaft turning.

“For the TMZ, many of our potential customers making the 19-mm and smaller diameter parts run medium complex work across a stable of Swiss-type, single-spindle machines,” he says. “The idea was to develop this Penta model at a price point competitive with what five Swiss machines would cost a shop and provide better cycle times.”

A CNC multi-spindle that machines medium complex parts and is capable of the performance cycle time because it can rotate the drum station to station more quickly than a six-spindle. The drum indexing time is 0.4 second on the Penta.

To help hit the price point, Penta uses standard, off-the-shelf drives and a FANUC CNC, which is capable of controlling 31 axes. This made the control a perfect fit for the five-spindle configuration, which only requires 25 axes. The use of this control also allows the machines to compete with the price point. Moreover, the FANUC brand is well known in the U.S. market.

What are medium complex parts? Mr. Tessaryzk defines them as “parts that require high precision tolerances, where complexity isn’t defined by operations performed. It’s about the number of features that must be machined. Generally, we consider 30 to 40 features to be typical of a medium-complex workpiece.”

A Different Approach to Independent Spindles

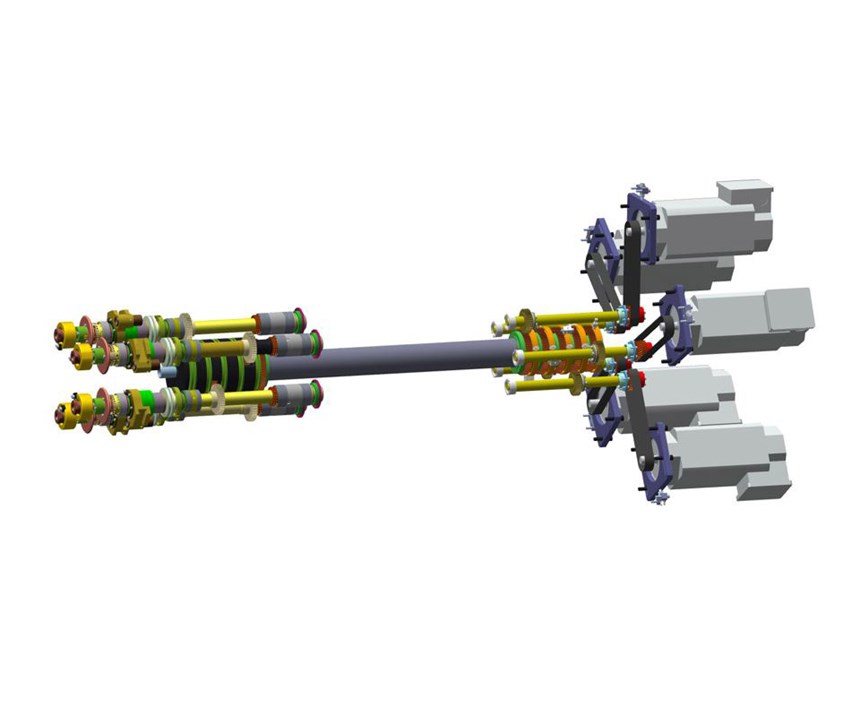

On its independent spindle machines—in this case the Penta model TMZ—ZPS approaches the issue of independent programmable spindle drives and spindle drum rotation with a unique configuration. The five FANUC spindle drive motors are mounted radially around the centerline of the center block, on the backworking side of the machine, outside the cutting zone.

Being removed from the work zone, their heat generation does not affect thermal stability of the critical spindle drum’s pitch diameter. Therefore, the spindle drum is relatively simple, uncluttered and doesn’t require active cooling.

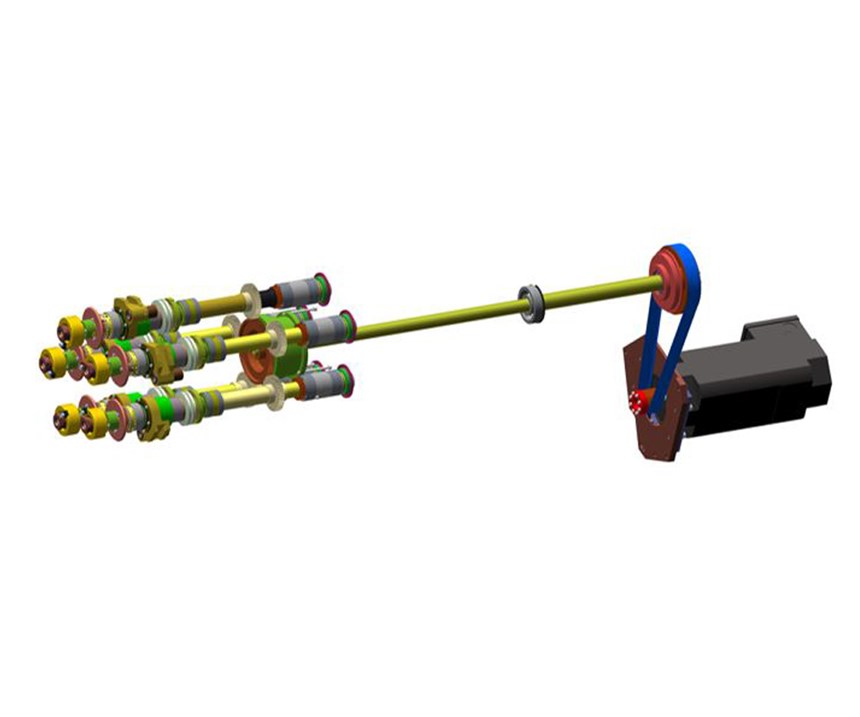

So how does the Penta spindle motor rotate the main spindles in the drum at the opposite end of the lathe? Power is transmitted from each drive motor to its individual main spindle using a central drive shaft that runs through the hollow centerline of the center block.

Each spindle needs its own drive shaft. Therefore, they are designed to independently run one inside the other, like a folded telescope. The smallest shaft runs inside the next smallest, and so on, transmitting the programmed rotation speed to its respective spindle.

A toothed belt connects each spindle drive to an idle shaft that is geared to one of the drive shafts. The drive shaft gears are staggered, so each meshes with its idle shaft.

On the main spindle end, in the drum, a similar staggering of the geared drive shafts meshes with its gear on the spindle and transmits rotation to the spindle. The spindle gears are set up in a planetary arrangement, allowing the spindle drum to rotate freely about its axis. The configuration is clever—it allows for constant engagement between the spindle drive and main spindle. This, in turn, allows main spindle speed changes to be done “on-the-fly” or, in other words, a spindle change from 2,000 rpm to 2,500 rpm can be done as the drum moves from station to station.

Because the drive shafts are relatively long and use bull gears, backlash was a concern on the Penta design. To make sure that backlash could be controlled, an additional encoder is used on the spindle end of the drive tube, where it provides absolute positioning for the spindle. Basically, it calculates the programmed position of the spindle through a drive motor encoder, and the actual position of the spindle. This compensates for any backlash that may occur during the power transfer from drive to spindle. Three degrees before reaching the programmed position, the brake begins to engage, which loads up the gears, eliminating backlash.

An electronic disc brake on each spindle mechanically locks the spindle end of the drive tube, secures the spindle for cross drilling operations and C-axis milling operations and, combined with the double encoder system, ensures accurate positioning for critical features.

Moving Ahead

The multi-spindle concept of progressive machining seems to be enjoying a renaissance in precision machined parts. We see builders applying CNC technology to this century-old idea and rediscovering how well it can work when matched with the right application. Increasingly, multi-spindle builders are following the GM principle by making tools for “every purse and purpose

Related Content

DN Solutions Announces Twin-Spindle, Twin-Turret Horizontal Turning Center

IMTS 2024: DN Solutions introduces a twin spindle, twin-turret horizontal turning center with 4″ bar capacity for increased productivity and simultaneous machining performance.

Read MoreMethods Multitasking Machine Reduces Cycle Times

Methods Machine Tools Inc. introduces Nakamura-Tome’s WY-100V two-turret, twin-spindle precision CNC multitasking lathe to the U.S. market.

Read MoreStriving for Faster Changeovers for Multispindles

A multispindle platform designed to combine the high production speed of a cam-driven machine with the precision and repeatability of CNC also includes technology to speed set ups for new jobs.

Read MoreMultispindle Automatic Lathe With Full System Concept

PMTS 2023: Tajmac’s Penta TMZ 518 is a five-spindle automatic lathe that features an island concept which offers the machine as a package.

Read MoreRead Next

Do You Have Single Points of Failure?

Plans need to be in place before a catastrophic event occurs.

Read MoreSeeing Automated Workpiece Measurement in Real Time

User-friendly inspection software for CNC machining centers was shown at IMTS 2024 monitoring measurements between and after machining while performing SPC based on recorded measurement values.

Read MoreA Tooling Workshop Worth a Visit

Marubeni Citizen-Cincom’s tooling and accessory workshop offers a chance to learn more about ancillary devices that can boost machining efficiency and capability.

Read More