How to Collect and Use Machine Data

Manufacturers don’t need to limit the machine monitoring data they collect, but they do need to know how to collect the data and how to use it to drive decisions.

Manufacturers have begun to shift how they view machine monitoring. They no longer want machine monitoring—they feel like they need it. But before diving in, shops should have an understanding of what types of data they can collect, and how to use this data to help drive decision making.

Shops can collect many different types of machining data efficiently and cost effectively. Because of this, shops don’t need to limit the data they collect, but they do need a system that can analyze the data and present it in a usable way.

With so many potential data points to collect, manufacturers may think the first step is to decide what to monitor. However, according to machine monitoring software provider MachineMetrics, this is not the case. Because the architecture for gathering data is relatively inexpensive, shops don’t need to limit what they collect. Data can be collected in an efficient and cost-effective way directly from the machine, from outside systems (such as CAM or enterprise resource planning [ERP] programs) and via sensors.

Once shops begin collecting all of this data, they have to figure out how to use the information gathered to their benefit. It can be easy to feel overwhelmed by data, especially if shops aren’t limiting what they collect. But having a system that processes the data on the back end and presents it in an actionable form (such as dashboards showing real-time information and email or text notifications of pending problems) makes it easy for shops to use their data to make decisions.

How to Collect Data

Shops can gather valuable data directly from the machine tool, but it often has gaps that need to be filled by other sources. For example, MachineMetrics’ user interface allows operators to enter data explaining why a machine is down without an alarm.

Manufacturers can collect machining data from several sources:

- Machine Tools. The machine tool itself is the source of some of the most valuable data. This includes statuses, modes, alarms, overrides, loads, speeds and feeds. MachineMetrics collects this information by connecting to machine tools via ethernet.

- Connected Systems. Machine tool data often has gaps that need to be filled. MachineMetrics has application programming interfaces (APIs) that can pull in information from outside sources, such as ERP, CAM, and tooling and maintenance systems. These can give context for machine data, like which part number is running or what’s required to fulfill a work order.

- Operators. Some gaps can only be filled by operators. MachineMetrics has an interface that enables machine operators to provide this missing data. For example, if a machine is idle without an alarm, the operator can provide information that explains why.

- Sensors. Manufacturers can also gather data via sensors. These sensors can either be on the machine (measuring temperature, vibration or power draw from the spindle) or elsewhere on the shop floor. Because sensors can be located virtually anywhere throughout a shop and do not require batteries, they are a low-maintenance way to gather many types of information. For example, because machine tools are sensitive to changes in humidity, MachineMetrics is considering the use of sensors to measure shopfloor humidity and its effects on machine tool operation.

How to Use Data

One of the simplest ways to manufacturers to use machining data is displaying it on the shop floor. This gives machine operators an awareness that can cause behavioral changes, improving shopfloor productivity by about 10%, according to MachineMetrics’ estimates.

Once the data is gathered, manufacturers must find a way to use it. Fortunately, there are many easy ways for manufacturers that are new to machine monitoring to put data to good use:

- Visibility. According to MachineMetrics, simply displaying the tracked data gives machine operators an awareness that can cause behavioral changes, improving shopfloor productivity by about 10%.

However, the data must be interpreted and shown in a way that is helpful to users. Giving too much data or data that is in an unusable format isn’t helpful. This is where MachineMetrics believes it has an advantage. Because it is rooted in the physical world, manufacturing data is different from data pulled from digital sources. Using a platform that is designed for manufacturing data can make it easier to interpret and use the data. The position of and load on an axes should have a consistent relationship over time. If those two data points decouple, it can indicate a problem on the machine. Companies with experience in manufacturing understand the relationship between these two data points, but it might be difficult to figure out that relationship using only analytical methods.

-

MachineMetrics uses its foundation in manufacturing to provide a user interface that is designed to make real-time information available to users as they want without overwhelming them. It also uses algorithms to help users interpret data. MachineMetrics has an algorithm to detect anomalies on unsupervised machines. It uses data from many sources, and if users were to look at all the raw data, they would probably not be able to make sense of it. But with the help of the algorithm, data can show anomalies.

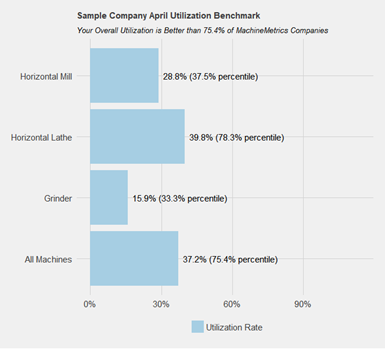

- Benchmarking. When shops have been collecting data for a few weeks, they can

establish baselines to help determine utilization rates. Machine utilization on its own is helpful for a shop to have, but it can also be used for benchmarking. Each month, MachineMetrics sends users a report showing which percentile they fall into compared with similar companies. This can help them determine how well they are doing, and whether they should invest in more capacity or processes that improve existing capacity.

- Pending Problems. The next stage of machine monitoring data is giving users real-time notifications of problems with machines based on the data. MachineMetrics can notify users via email or text when problems occur, such as when machines go down or when cycle times fall.

- Predictability. Data can also help predict when problems are likely to occur, enabling shops to prevent them before they happen. For example, data from a vibration sensor on a machine’s housing can indicate when a machine is about to fail. Or a current transducer that clamps onto the power draw for the spindle to measure how much power is being used during cutting operations can show how tools draw more power as tools get dull and are used to predict when they are about to fail.

According to MachineMetrics, once a shop implements a machine monitoring system, it can begin taking advantage of it immediately by making the data visible and tracking pending problems. At the same time, shops can build up a database for benchmarking and predictive analytics. But without the first step of choosing a platform that presents data in an actionable form, shops may have a difficult time taking advantage of their data.

MachineMetrics | 844-822-0664 | machinemetrics.com

Related Content

Tips for Cleaning Oily Parts

Degreasers are the best option for cleaning parts machined with oil. Vacuum degreasers are recommended for cleaning complex parts.

Read MoreWhen a CNC Turn-Mill Doesn’t Turn

A shop in Big Sky Country uses a B-axis multitasking machine to produce complex, prismatic medical parts that require no turning complete from barstock.

Read MoreVideo: Why a Production Machine Shop Started a Baseball Bat Company

A 153-year-old manufacturer of precision, metal pins recently started a side business creating custom wooden baseball bats. The reasoning behind establishing this new company is intriguing, as is how it has helped create a stronger bond with the local community.

Read More6 Tips for Training on a Swiss-Type Lathe

There are nuances to training a person to effectively operate a Swiss-type lathe. A shop I visited a while back offers some suggestions.

Read MoreRead Next

A Tooling Workshop Worth a Visit

Marubeni Citizen-Cincom’s tooling and accessory workshop offers a chance to learn more about ancillary devices that can boost machining efficiency and capability.

Read MoreSeeing Automated Workpiece Measurement in Real Time

User-friendly inspection software for CNC machining centers was shown at IMTS 2024 monitoring measurements between and after machining while performing SPC based on recorded measurement values.

Read MoreDo You Have Single Points of Failure?

Plans need to be in place before a catastrophic event occurs.

Read More