Can Machining Metal 3D-Printed Parts be a New Business Opportunity?

Perhaps. And shops could use their existing CNC machines to remove 3D part-print supports, to trim parts and so on. But dedicated robotic machining systems could be an alternative.

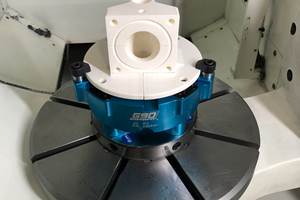

Having dedicated, robotic postprocessing capability could be helpful for CNC machine shops that are considering bringing metal AM in house. Source (all photos): Rivelin Robotics

Metal 3D printing technology is becoming more accepted and is enabling higher part production volumes. That said, 3D printing is only one component of additive manufacturing (AM). AM also includes subsequent postprocessing steps to remove print supports and to trim, polish and generally finish a metal 3D-printed part.

It’s not uncommon for companies printing metal parts to outsource postprocessing. In fact, this could be a business opportunity for traditional CNC machine shops. One alternative is for a shop to use its conventional production CNC machine tools. But is it worth tying up what often are high-dollar machines for this type of work?

While that’s an option, another perhaps more cost-effective alternative might be robotic post-processing equipment dedicated to this work, such as that offered by Rivelin Robotics.

David Alatorre, the company’s CTO, notes that essential postprocessing of these often complex parts introduces time and financial constraints to the overall cost-per-part that can negate the benefits of AM altogether. He says that support removal is the critical first step of postprocessing metal AM parts, and it is a challenging one. Today, supports are still essential for part fidelity during the manufacturing process, but they must be removed to achieve the required finished product with the intended shape, features and tolerances.

But, while manual support removal is still the status quo for many applications of metal 3D printing, there are advantages to transitioning to automated support removal (and finishing) using CNC processes and robots. What follows are Alatorre’s thoughts about these options.

Print Supports Remain a Necessary Evil

There is an argument that the support removal conundrum in AM will eventually be resolved by so-called support-free printing. Of course, this would be the goal, enabling complete design freedom with optimized resource efficiency whereby raw materials and energy are only being used to make the final part and not the supports.

Unfortunately, the AM sector is not there yet. And, while supports are being minimized through design, they are still a necessity and will be for the foreseeable future. Minimizing the amount of material and energy used for supports is the right thing to do in almost every situation, but it can also compromise design freedom and have a negative impact on the desired functionality of the end-use part, which may, for example, need to be designed with filled cavities or overhangs leading to loss of light-weighting. Generative designs might also be unnecessarily constrained to get the angles needed for reduced supports.

In short, while it’s healthy for the industry to strive for less supports, they are currently still a necessary tool for most complex AM applications.

Manual Versus Automated CNC Postprocessing

It might be surprising to know that manual support removal remains the process of choice for the majority of AM users today. This requires highly trained technicians to remove supports with all manner of traditional hand tools. Dremels can be useful too. However, these tried and tested devices require skill, creativity and problem-solving capabilities. They still can be well suited to high-mix, low-volume production environments.

But manual support removal is also very time-consuming, labor-intensive, messy, with toxic dust requiring PPE or shielded environments. Risk of powder ignition and explosion, and repetitive strain injuries are common problems. In addition, it is not accurately repeatable with variability from person to person and even from shift to shift causing quality control problems and increases in scrap rate. It is also difficult to scale if the demand for AM parts begins to increase significantly.

This is why automated postprocessing can be an attractive alternative. There has been some progress with solutions for automating the postprocessing of metal AM parts. The most common has been the use of CNC milling machines, a proven technology for a variety of manufacturing applications (including a hybrid approach to AM). These machines are accurate and repeatable. However, this doesn’t mean they are the best solution for AM postprocessing.

CNC milling machines can work well if the part in question has tight-tolerance features, and where flatness, circularity, concentricity or dimensions have to be within a few microns. It is also the preferred technology for support removal in large batch builds in which geometries are simple or lend themselves to easy fixturing in only a couple of orientations. Similarly, it can be a good fit for prints in which platform removal with a CNC electrical discharge machine (EDM) takes care of the majority of supports.

However, CNC machines are not a good solution for thin-walled components, space-saving stacked builds and parts with lattice structures or breakaway supports. It is also fair to say that CNC programmers don’t like one-off, generatively designed organic shapes with compound curves.

Rivelin’s Netshape Robots offer what the company feels is a cleaner approach for metal postprocessing and closes the gap that exists in AM’s digital process chain by removing manual finishing steps. Automation is the key, with eight-axis robots (six-axis robots and two-axis positioner) driven by Netshape software which not only automates the support removal and finishing steps, but also provides process data, reliability, consistency and traceability.

Robotic systems using metalworking tools to finish, trim and polish a wide range of metallic materials offer a range of advantages over manual operations and conventional CNC machining.

AM needs automation that can adapt to variability, especially for support and witness removal. And this challenge has been solved through the use of advanced software and artificial intelligence systems to help generate tool paths and robot motions without mobilizing an entire systems-engineering team. This then allows for quick iteration as well as automation of small batches.

In addition, 3D scanning can be used to locate parts instead of high-precision fixtures, which means desktop fused deposition modeling (FDM) printers can be used to make plastic fixtures quickly without worrying about accuracy or changes to the design. In addition, force sensors can be used to feel the surface and adapt the machining accordingly, to spend more time on high spots until the final shape is reached or to polish to a consistent finish.

One advantage is that any tool can be used for support removal and finishing. If it is already known what tools work well with the materials or the types of supports printed, the same tools can be attached to a robot to automate with more confidence. With today’s technology, the steps to add a new custom tool are basically like adding a new type of end mill to a CNC machine, and does not require a system integrator that charges by the hour.

Postprocessing Beyond Supports

Robert Bush, Rivelin Robotics’ CEO, says support removal is, by far, the most labor-intensive part of AM postprocessing. But as he explains below, there are other aspects of postprocessing which automation can be a benefit, such as:

Powder removal. Due to the nature of the powder bed fusion (PBF) process, whether that’s with lasers or electron beams, unsintered and semi-sintered powder will remain within holes and internal channels of AM components. If it is not removed, the residual powder can seriously compromise part functionality. The manual work required to remove powder is hazardous and results can vary from part to part. This variability presents a complex risk in product development that can be costly to manage and resolve.

Conversely, Netshape robots uses a combination of pneumatic and electromechanical tools to release caked, semi-sintered and un-sintered powder from metal parts. They can adapt to variability in the condition and location of holes, corners and channels using a 3D vision system and dynamic planning capability. Rivelin’s automated calibration system enables engineers and technicians to quickly set up and start production runs using their existing levels of knowledge and intuition.

Platform removal. Printed metal parts produced using the PBF process are removed from the machine attached to a rigid metal platform. Again, this is due to the inherent nature of the process and is necessary for a successful build. Wire EDM is frequently used to de-platform parts, but it can be unreliable around metal powder due to shorting and wire breakages. Another alternative is to use conventional tools such as bandsaws to break the part away from the base plate, but these can be susceptible to drift without any form of positional feedback. It’s an unreliable process at best, and might require rework. At worst, parts have to be scrapped completely. In addition, both methods are expensive and require large-footprint machines that require skilled operation. If the job is outsourced, it adds considerably to the lead time and overall costs of the part.

That said, Netshape robots can accommodate end-of-arm tools that can remove base plates in a wide range of materials, while adapting to warping and variability via the 3D vision system and dynamic planning capability. It includes a grinding-specific force control system that reacts and stabilizes non-linear machining forces. In addition, autonomous Netshape programming capability enables engineers and technicians with no prior robotics experience to quickly create robot trajectories and tool operations.

Finishing and polishing. Parts produced via PBF processes often exhibit high surface roughness and visible layers due to the nature of the process. For some applications the surface finish is a non-issue and polishing is not required. However, for many applications, it is. To date, localized polishing has typically been carried out by hand or in a rigid machine tool. The latter of these two is also expensive and introduces other quality issues due to the surface variability often found in AM parts.

Robotic systems using metalworking tools to finish, trim and polish a wide range of metallic materials offer a range of advantages over manual operations and conventional CNC machining. They also could offer a means to explore new business opportunities for traditional machine shops.

Related Content

Digitalization and Done-In-One Reign Supreme at BIEMH 2024

European manufacturers may have a different balance of markets than their U.S. counterparts, but the practical challenges they must overcome are often similar — as are the solutions.

Read More5 Big Themes in Additive Manufacturing at Formnext Forum: Austin

As manufacturing advances with additive, the advance increasingly emphasizes these five themes.

Read MoreUpgrading Bar Feeder Components with Metal 3D Printing

Index is exploring redesigning and optimizing parts for bar feeders inside its multi-spindle turning centers using a low-cost metal 3D printing platform from One Click Metal.

Read MoreChuck Jaws Achieve 77% Weight Reduction Through 3D Printing

Alpha Precision Group (APG) has developed an innovative workholding design for faster spindle speeds through sinter-based additive manufacturing.

Read MoreRead Next

5 Aspects of PMTS I Appreciate

The three-day edition of the 2025 Precision Machining Technology Show kicks off at the start of April. I’ll be there, and here are some reasons why.

Read MoreA Tooling Workshop Worth a Visit

Marubeni Citizen-Cincom’s tooling and accessory workshop offers a chance to learn more about ancillary devices that can boost machining efficiency and capability.

Read MoreDo You Have Single Points of Failure?

Plans need to be in place before a catastrophic event occurs.

Read More

.jpg;maxWidth=300;quality=90)