Multitasking With Brand Loyalty

SureFire LLC (Fountain Valley, California) has found one name in machine tools it can trust, and therefore, has invested in several different types of machines with at least one thing in common—the name "Index" in large letters written on the machines’ bodies.

SureFire LLC (Fountain Valley, California) has found one name in machine tools it can trust, and therefore, has invested in several different types of machines with at least one thing in common—the name “Index” in large letters written on the machines’ bodies.

The strategy of being loyal to machine tools from Index Corp. (Noblesville, Indiana) has worked well for SureFire, helping it keep its products ahead of the competition. Because the company uses only Index machines, personnel need to be trained on only one type of machine, the same tooling system is used throughout, and spare parts can be shared. That saves the company training costs, machine downtime and replacement part costs, making its processes more efficient and cost effective overall.

Machining Quality Parts

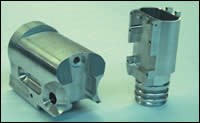

SureFire’s aluminum-body lights are machined from a high-strength, aerospace-grade alloy, making them resistant to damage from impact, crushing or bending and allowing them to be made as small and light as possible without sacrificing strength.

To do so, the facility relies on Index’s multitask milling and turning machines, as well as its CNC multi-spindle machines and automatic lathes. With this technology, the company has found ways to minimize cycle times and reduce the need for operator attendance.

According to Gustav Bonse, SureFire’s chief operating officer, “The reason we are so successful with the Index machines is that they drop complex parts complete. The cycle times are very fast, and the machines do not require constant operator attendance.”

The company produces almost 300 different kinds of parts, shipping to its assembly plants between 125,000 and 200,000 complete stainless, aluminum and Inconel parts per week. “Each part will have from eight to 35 operations,” Mr. Bonse explains. “That is why we have almost a dozen Index G200 turning machines, two of which we use for prototype work only. Some are simple, and several provide us with Y- and B-axis capability.”

There are less expensive machines available, but Mr. Bonse explains his choice this way: “We do not look at the cost of the equipment, but at what it really costs us to produce a part. This is what drives me. If it is cheaper with an expensive machine, then it is worth the cost. For example, since I can drop a part in one operation, I do not have anyone unloading and rechucking the part or moving it to another machine for secondary operations.”

One part that is produced by SureFire is done on the G200, and 29 live tools are needed. “There are only 14 tools in each of the two turrets, so we double up on toolholders in some turret stations. This part was quoted by outside vendors at $120 each. We do it in 9 minutes for each part, and that costs us much less,” Mr. Bonse explains.

Maxing Out Capabilities

Another way these machines pay for themselves is by using them to the full extent of their capabilities. SureFire operators also are careful to assign parts to the appropriate machine.

“The G200 provides us flexibility in both processing and change-over. I can tool it up tomorrow for a different part,” Mr. Bonse says. “Our setup times in the shop may be 1 minute to 1.5 days, depending on how many tools we have to change and whether we have to change bar feeders. In most cases, the G200 always runs the same bar size and is already tooled up to produce four to five different parts each, so all we have to do is change part programs, and setup is done in a minute or less.”

SureFire programs the prototype machines, supported by an Index Turbo H200 programming system, which is designed to create part programs faster. It proves out the programs on the prototype G200, and then uses it on the production machine so at least 80 percent of the programming is done when it has finished the prototype.

Outfitting the plant with machining capability is part of a carefully thought out strategy, according to Mr. Bonse. “We have this selection of machines for a reason: This complement of machine tools is what lets us make the parts we need in the quantities we need when we need them. It is a balanced combination of speed, flexibility and change-over. The only changes anticipated are to increase production capacity throughout the next 2 years. We already have several more machines on order.”

Each machine has a bar loader to allow SureFire to continue running unmanned operations, assigning one operator to several machines.

The Multi-Spindle

SureFire’s lot sizes for its Index multi-spindle (MS) range from 20,000 to 1.2 million. It achieves a cycle time of 2.7 seconds on one of the parts it machines. The MS handles part diameters to 32 mm and lengths to 2 inches, with simple to medium complexity.

“Our payback time on the MS machine will be less than 2 years,” Mr. Bonse says. “Some of the parts we had on the ABC (Index’s automatic lathe) had 24-second cycles, and now on the MS they are complete in 2.8 seconds, doing the work of four ABCs. So I save floor space, need fewer operators, and the machine is flexible and can be set up for most jobs in about 4 hours, compared to 2 to 7 days for a cam-driven multi-spindle.”

The multi-spindle MS-32 at the plant is a CNC double, three-spindle arrangement that allows SureFire to produce two parts in one cycle. It can be changed over to a standard six-spindle arrangement, but the company runs it with three spindles for jobs producing several different parts, such as an end cap, because of the cycle time savings.

Meeting Challenges

Holding tight tolerances can sometimes be challenging in the metalworking industry, but because SureFire uses reliable machines, it doesn’t worry about reaching these tolerances or the resulting quality. “The machines on the floor help us to create quality and tolerances to 0.0005", even with some tough stainless, like 17-4, 304, Inconel, and other materials,” Mr. Bonse states.

Product design is also not a concern. “Our engineering department does all of our product design, but we also work closely with manufacturing to sort out producibility issues. The designs are intentionally challenging to produce, so they are not only extremely functional and durable, but extremely difficult to copy. Index helps us get there and to be cost-effective producers,” he continues.

Being loyal to one name brand has allowed SureFire to manufacture a leading product produced in a plant that tightly controls cost—a recipe for success in any industry.

Read Next

Competing On A Multi-Spindle

For many high-volume applications, multi-spindle automatics are the right technology for production machining. Increasingly, that production efficiency has been pressured by changes in the needs of shops in the form of shorter run jobs and higher tolerances. This article looks at some of the steps one OEM has taken to address quick change-over issues on its multi-spindle machines and their tooling.

Read MoreSeeing Automated Workpiece Measurement in Real Time

User-friendly inspection software for CNC machining centers was shown at IMTS 2024 monitoring measurements between and after machining while performing SPC based on recorded measurement values.

Read More5 Aspects of PMTS I Appreciate

The three-day edition of the 2025 Precision Machining Technology Show kicks off at the start of April. I’ll be there, and here are some reasons why.

Read More

.jpg;maxWidth=300;quality=90)