New Machine for Production Turning

In February, PM was invited to a DMG/Mori Seiki press conference at the company’s facility in Pfronten, Germany.

In February, PM was invited to a DMG/Mori Seiki press conference at the company’s facility in Pfronten, Germany. Among the machine tools on display was a production turning center that is designed to run bar, shaft and chucked parts in a production environment.

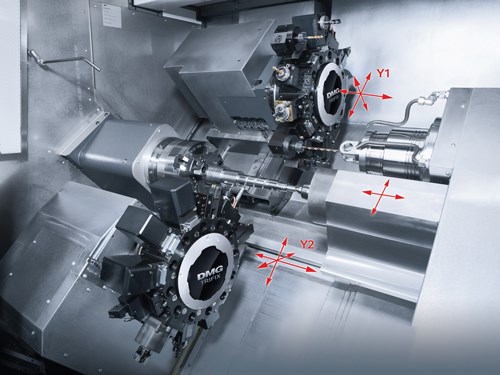

At its world premiere, the CTX beta 800 4A turning center, combines quite a number of innovative details and designed to provide a unique overall performance in the field of medium sized production turning of workpieces up to 735-mm turning length and 300-mm diameter respectively, for chucked parts and as large as 102-mm diameter for working through the spindle.

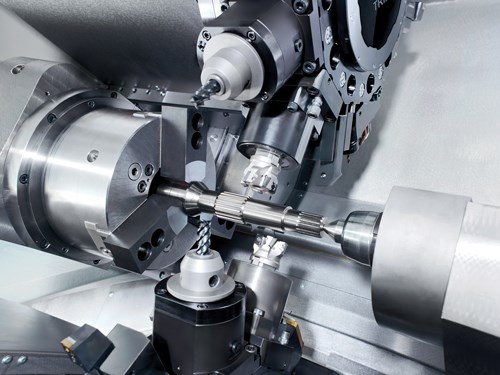

Particular features include the company’s direct drive system for live tooling in both 12-station turrets to facilitate complex turning and milling operations. The machine also uses the company’s quick tool change system as well as the counterspindle tailstock combination, which can be positioned for four-axis machining that supports at the main spindle or for parallel machining at the main and counterspindle.

The main spindle operates with integrated spindle motors either in the ISM 76 or ISM 102 version, while on the second spindle an ISM 76 spindle is used. For turning operations, the two spindles provide an rpm to as high as 5,000 rpm with 360 Nm torque as standard.

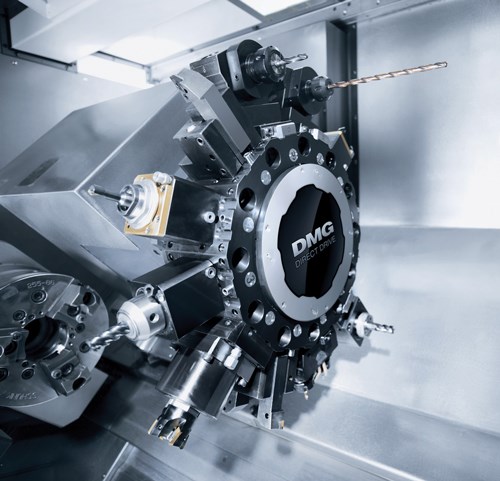

Direct Drive Tools

The company’s direct drive system’s turrets supply the driven tools with 34-Nm torque and speeds as high as 10,000 rpm each. Both turrets using this system have a Y axis, whereby the top turret provides an operational range of ±60 mm, while the bottom turret is traversable by ±40 mm in the Y direction.

Liquid cooled spindles provide temperature stability in the process and (together with the direct measuring systems in the X axes) production stability and precision, while rapid traverse speeds of as much as 45 m/min keep process times to a minimum.

Quick-Change Tool Interface

Both direct drive turrets are equipped with the company’s precision interface, called Trifix, at all tool stations as a standard. Complicated adjusting inside the machine is now a thing of the past. Instead, the tools are positioned in the fixture when changing with the tool system’s interface, which decreases setup time by as much as 80 percent.

Furthermore, the system provides excellent repeat accuracy in the micron range and a highly stable toolholder. This ensures maximum precision and a safe process even with difficult component materials.

Powerful CNC Simplifies Programming

On the programming side, the new turning center is equipped with the Siemens 840D Solutionline. Imbedded in the control is a programming package called ShopTurn 3G, which provides more than only the basic machining processes such as contour turning, piercing and recess turning or form, track and thread milling. Complex, multi-axis, simultaneous machining requires the ability to handle significantly higher data transmission. Two-channel programming of the top and bottom turret is used for two-sided machining or up to four-axis milling with both turrets on the main and counter spindle.

Furthermore, with regard to control intelligence, the control represents an apex in CNC technology, bringing together the resources and experience of DMG and Mori Seiki in its development and specifications. These developments can be seen in particular by the specifically generated special technology cycles in the form of non-circular machining, multi-sided machining, in-process measuring or efficient usage of special tools.

Customer-specific machine options and process control can also be implemented quickly with the imbedded programming package—for use of auxiliary components such as steady rests or turret-head steady rests as well as devices for parts handling. The control also provides application images for fast configuration and simulation, while DMG’s soft keys feature enable integration of additional as well as further status information.

Related Content

Precision Machining Technology Review: September 2024

Production Machining’s September 2024 technology showcase includes some of the latest technology from Expand Machinery, Paperless Parts, Monaghan Tooling Group, Walter USA and more.

Read MoreReinventing the Wheel with Robot-Automated CNC Multitasking

One race team discovers how to efficiently manufacture a new wheel nut design for the next-generation NASCAR stock car with the help of a CNC mill/turn and a built-in robot.

Read MoreGetting More Production From Swiss Turning Centers

Buying a new CNC Swiss turning center is a substantial investment. For the best return, look closely for capabilities that enable the best utilization of the machine.

Read MoreNomura DS Showcases Turning and Milling Machines Engineered with Excellence

Gosiger offers the comprehensive line of Nomura DS machine tools at competitive prices.

Read MoreRead Next

Do You Have Single Points of Failure?

Plans need to be in place before a catastrophic event occurs.

Read MoreA Tooling Workshop Worth a Visit

Marubeni Citizen-Cincom’s tooling and accessory workshop offers a chance to learn more about ancillary devices that can boost machining efficiency and capability.

Read MoreSeeing Automated Workpiece Measurement in Real Time

User-friendly inspection software for CNC machining centers was shown at IMTS 2024 monitoring measurements between and after machining while performing SPC based on recorded measurement values.

Read More

.jpg;maxWidth=300;quality=90)