Personal Protective Equipment And The Precision Machining Industry

If the OSHA inspector arrived today, would your system provide documented evidence of training, enforcement and retraining?

Personal protective equipment (PPE) is required when engineering and administrative controls are neither feasible nor effective in reducing employee exposure to hazards to acceptable levels. Employers are required to determine if PPE should be used to protect their workers.

A recently published guidance document addresses the question of who should pay for PPE. This final rule goes into effect May 15. You can find the OSHA guidance document here.

As employers, we have an even greater duty. That is, to have a system in place to ensure that our investment in PPE is effective and is protecting the safety of our employees. In all areas of our businesses, we implement systems with documented procedures to ensure performance.

What does your PPE system documentation look like? Where does it live? If the OSHA inspector arrived today, would your system provide documented evidence of training, enforcement and retraining? Or, would you rush to the purchasing department (the wrong place) to see if it has anything in its files on safety supplies?

Where protective equipment is to be used, the employer should implement a PPE program. This program should document the hazards present, the selection, maintenance and use of PPE, the training of employees, and the monitoring of the program to ensure its ongoing effectiveness.

Where can you go for this information? OSHA Publication 3151 (2003) is a free, 46-page guide that discusses the types of equipment most commonly used for employee protection. It also includes information on requirements, hazard assessment, selection and employee training. Obtaining a copy is easy. Here’s the link to a downloadable pdf file.

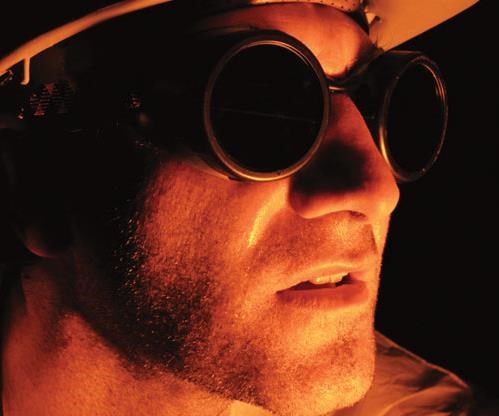

Eye protection. What PPE is called for in the machine trades? Employers must be sure that their employees wear appropriate eye and face protection. They must also make sure the selected form of protection is both appropriate to the work being performed and that it properly fits each exposed worker.

At a minimum, OSHA suggests that eye protection be routinely considered for use by carpenters, electricians, machinists, mechanics, millwrights, plumbers, pipefitters, sheet metal workers, tinsmiths, assemblers, sanders, grinding machine operators, sawyers, welders, laborers, chemical process operators and handlers, among others. That covers most of our occupations (and most of our after-hours work around the home and garage, as well).

When choosing PPE for your employees, you should take into consideration the ability to protect them against specific workplace hazards. The protective equipment should fit properly and be reasonably comfortable to wear. And, it should provide unrestricted vision and movement.In our shops, it’s important for PPE to be both durable and cleanable. The eye and face protection must clearly identify the manufacturer. Any new protective devices must comply with ANSI Z87.1-1989. Goggles and face shields might also be required based on your hazard analysis. Welding, torch cutting and laser equipment need additional consideration, if performed in your shop.

Protective footwear. Employees who face possible foot or leg injuries from falling or rolling objects, or from crushing or penetrating materials, should wear protective footwear.

Some examples of situations in which foot protection should be worn include employees working in places where heavy objects, such as barrels, tools or materials, might roll onto or fall on their feet; employees working with sharp objects that could pierce the soles or uppers of ordinary shoes; and employees working on or around wet or slippery surfaces. Moving barrels or bundles of material can create crushing “pinch points” for employee’s feet.

Safety footwear must meet ANSI minimum compression and impact performance standards in ANSI Z41-1991 (the standard for Personal Protection-Protective Footwear) or provide equivalent protection. All ANSI-approved footwear has a protective toe and offers impact and compression protection. But the type and amount of protection is not always the same. Different footwear protects in different ways. Check the product’s labeling or consult the manufacturer to make sure the footwear will protect employees from the hazards they face.

The fact that we do not have cauldrons of splashing molten metal may make us feel safer than other industries. But heavy tools, workpieces and materials striking an employee’s foot can become a lost-time incident if protective footwear isn’t worn.

PPE: An investment in safety. Personal protective equipment represents a company’s best effort to ensure employee safety in addition to properly deployed engineering- and work-practice controls. It also is the result of the company’s investment in ensuring a safe workplace.

Like other investments, the investment in PPE must be managed in a planned and thoughtful way. Training should be documented with follow-ups performed to ensure that the training was effective.

Training is the key to keeping our employees safe. Monitoring effectiveness of that training is the key to keeping our workplaces safe. Documenting and reviewing both are key to administrative compliance.

— Precision Machined Products Association

Read Next

A Tooling Workshop Worth a Visit

Marubeni Citizen-Cincom’s tooling and accessory workshop offers a chance to learn more about ancillary devices that can boost machining efficiency and capability.

Read MoreDo You Have Single Points of Failure?

Plans need to be in place before a catastrophic event occurs.

Read MoreSeeing Automated Workpiece Measurement in Real Time

User-friendly inspection software for CNC machining centers was shown at IMTS 2024 monitoring measurements between and after machining while performing SPC based on recorded measurement values.

Read More