10. Embracing Second Chances: The Untapped Potential of Hiring the Justice-Impacted

In today's competitive job market, the need for skilled workers extends beyond precision machining to nearly every career field. While traditional trade schools are one source, they alone can't meet the demand. Companies can leverage employee referrals and tap into a valuable but often-overlooked talent pool: justice-impacted individuals.

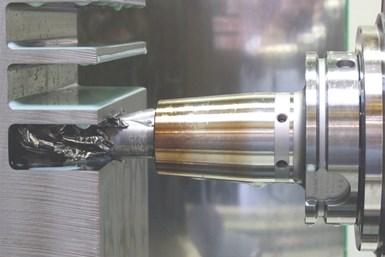

8. Simulated Complete Machining of EV Aluminum Inverter Cases

The number of robots on display at manufacturing trade shows continues to rise. At EMO 2023 in Hannover, Germany, FANUC America Corporation presented a simulated automated manufacturing cell producing aluminum electric vehicle (EV) inverter cases.

This production cell demonstrated the machining of these parts part in four and five axes using two Robodrill α-DiB Plus series machining centers including turning operations using DDR-HSiB high-speed rotary tables. Watch the demo.

6. Lone Shop Machinist Benefits From Five-Axis CAM Modules

Nick Katrov's decision to start his own machine shop wasn't just about wanting to be a one-man operation. With early machinist experience and years in management roles at major machine tool manufacturers and distributors, he worked with industry giants like General Electric, Pratt and Whitney, Rolls-Royce, and Bombardier. In this article, Katrov details five-axis strategies for more efficient milling of parts with challenging geometries, free-form surfaces and deep cavities.

4. One Shop’s Tale to More Standardized Tool Organization

Nearly every leading manufacturer today uses some aspect of lean manufacturing's 5S concept — Sort, Set in Order, Shine, Standardize, and Sustain — to maintain an organized workplace. Ogden, Utah's JD Machine Corp. is a prime example, though this wasn't always the case. Learn how they discovered a more sophisticated way to standardize tooling storage for its various production cells in this article.

2. Replaceable-Insert Spade Drill Basics, Advantages

Although solid carbide and indexable-insert drills have their place in a machine shop, replaceable-insert spade drills offer specific advantages for various holemaking operations on machining centers and lathes.

Read Next

Do You Have Single Points of Failure?

Plans need to be in place before a catastrophic event occurs.

Read MoreA Tooling Workshop Worth a Visit

Marubeni Citizen-Cincom’s tooling and accessory workshop offers a chance to learn more about ancillary devices that can boost machining efficiency and capability.

Read More5 Aspects of PMTS I Appreciate

The three-day edition of the 2025 Precision Machining Technology Show kicks off at the start of April. I’ll be there, and here are some reasons why.

Read More

.jpg;maxWidth=300;quality=90)