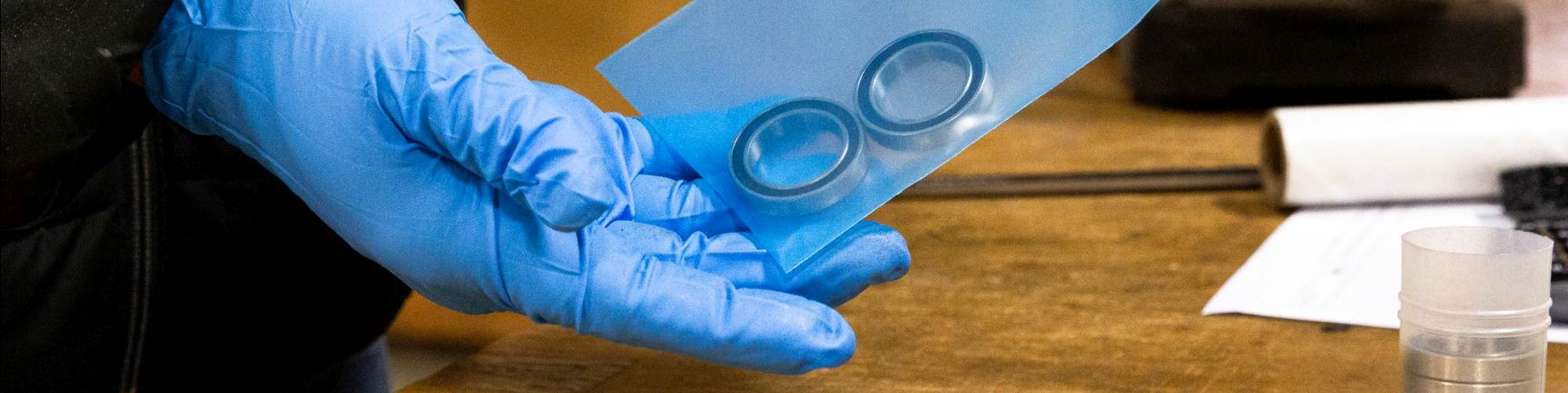

To prevent corrosion from developing on the surfaces of freshly machined parts, it is crucial to create a barrier on the parts’ surfaces so moisture and oxygen don’t reach them. (Photo Credits: Green Packaging Inc.)

As machine shops turn, mill or otherwise transform a piece of metal into a precision part held to extremely tight tolerances, newly exposed metal surfaces naturally come in contact with the corrosive atmosphere. Machining also imparts a great deal of energy into a metal part. This energy, combined with the presence of moisture and oxygen in the atmosphere, is a catalyst for rust and corrosion.

In addition, once machining is completed, a metal part often needs to be deburred, washed and rinsed, creating more opportunity for rust and corrosion to form. This is especially the case if a shop’s cleaning fluids are contaminated or its pH levels are incorrect.

Shops must then ask, after all these manufacturing processes have been completed, if it makes sense to risk leaving machined parts in the open and subject to atmospheric conditions prior to shipping to customers. This is especially important to consider during “rust season.” In the United States, rust season typically occurs from March through June when moisture in the atmosphere is high and temperatures are warm, creating a natural environment for rust and corrosion to develop.

To prevent corrosion from developing on the surfaces of freshly machined parts, it is crucial to create a barrier on the parts’ surfaces so moisture and oxygen don’t reach them. Traditional options for this include applying rust-preventive oils, greases, paint or other coatings. Although these methods work, they can be messy, labor intensive and environmentally unfriendly.

Paper with VCI technology is said to provide protection for machined parts on both sides of the paper.

Green Packaging Inc., suggests a safer, cleaner and more environmentally friendly option in vapor corrosion inhibitor (VCI) technology. VCI, the company says, is a complex blend of organic chemicals that, when used to enclose a metal part, is attracted to the metal surface due to its polarity. The VCI molecules are embedded in paper, poly bags or other protective materials into which metal parts are enclosed. As VCI molecules migrate out of one of these protective carriers, they are said to completely coat the surface of the metal, including all recessed areas such as holes. This is akin to traditional coating methods, but on a microscopic level.

Green Packaging offers numerous products within its Rust Guard Premium line that incorporate VCI technology, including transparent poly bags for small, metal parts; paper which provides complete protection on both sides of the paper; poly film designed to protect large, irregularly shaped products; and more. The company also offers consulting services and on-site rust prevention process analysis, and anticorrosion recommendations.

.jpg;maxWidth=300;quality=90)