Share

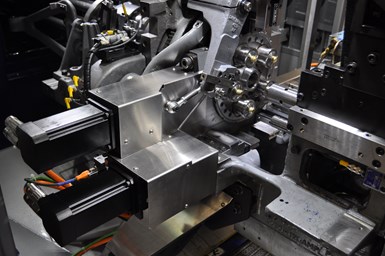

This machine combines the fast production capabilities of a multi-spindle cam screw machine with the programming and precision made possible through computer numerical control (CNC). Photo credits: Davenport Machine

The Davenport brand is no stranger to anyone in our precision machining industry. To estimate the total number of parts equipment such as the Model B multi-spindle has produced over the years would be impossible.

And a good number of these cam-actuated screw machines are still in use today. That said, Davenport Machine (part of Brinkman International Group Inc.), now offers the next evolution of these five-spindle machines — the Hybrid — which has been designed to realize tighter process control and precision, while also being simpler to operate and more flexible to set up and change over to new jobs.

Andy Laniak, Davenport Machine CEO, says the goal with the Hybrid was to preserve the production speed at which the company’s heritage multi-spindle platform is known for while offering repeatable CNC positioning accuracy with an intuitive computer interface that today’s machine operators, programmers and setup personnel would feel at home using. He adds that the Hybrid was also engineered to machine more challenging materials such as high-temperature alloys that might be used to produce parts including aerospace fasteners.

The CNC with touchscreen runs proprietary control software. Tool-to-spindle offsetting can be performed to adjust each spindle for part diameter and length for global offsetting capability. The control system also offers functions such as part counting, stock depletion sensing and spindle load monitoring.

Some of you might be familiar with this machine due to its introduction at the Precision Machining Technology Show (PMTS) in 2017. (Visit pmts.com to learn more about this year’s show August 10-12 in Cleveland.) However, a variety of design improvements and additions have been made since then. Here’s a quick breakdown of what the company says the latest iteration of the Hybrid machine, manufactured at its headquarters in Rochester, New York, currently features.

- Rigid base. An optimized casting geometry provides high rigidity while the machine base has integrated structural supports for improved vibration damping qualities. In addition, the revolving head/spindle carrier, based on the company’s HP design, mounts to the machine bed supported by 9-inch, preloaded angular contact bearings to help ensure consistent spindle positioning and faster indexing speed. Each spindle uses angular contact bearings for improved size control and part roundness as well.

- CNC-driven slides. The first- and second-position CNC-driven slides ride on preloaded linear rails with motion provided by servo-driven ballscrews (no cams or linkages are used). Similarly, the third and fifth positions feature CNC-driven swing arms rather than cams or turnbuckles. The fourth position with a two-axis (X-Z) slide can perform single-point turning and threading, 2D profiling and angular undercutting. It can also accept boring bar holders for complex internal contours and undercuts, and gang tools to perform both ID and OD work on the same slide.

- CNC running proprietary software. The Hybrid’s CNC with 15-inch touchscreen runs control software developed (and modified and updated) by Davenport Machine. Each slide axis can be programmed independently. Tool-to-spindle offsetting can be performed to adjust each spindle for part diameter and length. Once set, this offers global offsetting capability for each tool at each spindle to adjust for tool wear, for example. The control system also offers functions such as part counting, stock depletion sensing and spindle load monitoring.

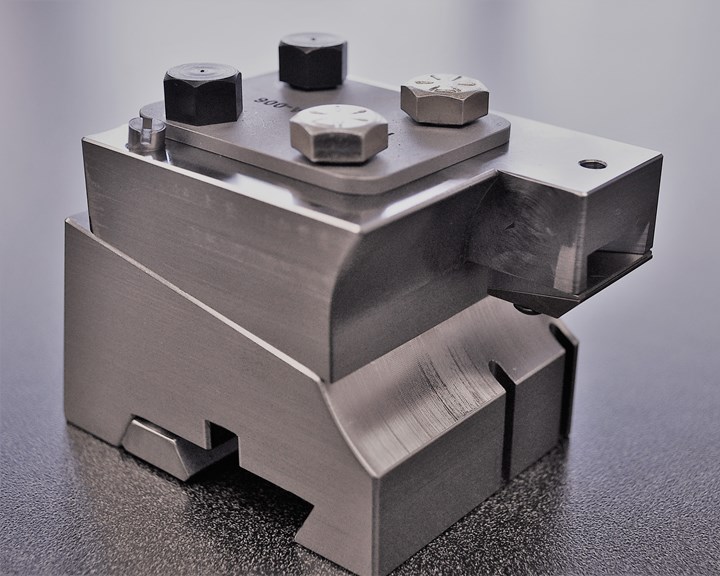

Quick-change dovetail tooling system facilitates fast setups for new jobs and accepts industry-standard carbide inserts, meaning special form tools are not required.

- Dovetail toolholding system. To help speed changeovers, the Hybrid features a quick-change dovetail tooling system available in skive, forming or standard 5/8-inch stick tool configurations to offer precise taper, height and length position adjustments. All toolholders include high-pressure (1,000-psi) through-tool coolant delivery ports to direct coolant to a tool’s cutting edge while eliminating the need for copper or adjustable nozzles in the work zone. (Coolant sump capacity is 200 gallons, and high-pressure coolant is a standard machine feature.) Tool modules accept conventional carbide inserts from various tooling suppliers, meaning specialty tooling isn’t required.

- Part removal options. Hybrid machines are available with three different part removal options. One is a traditional spring-loaded ejector that pushes parts to a chute within the machine. Alternately, parts can slide out of the back of the pickoff spindle for more gentle handling. Or, a system with a pneumatic parts chute leading to a conveyor can collect and deliver parts outside of the machine.

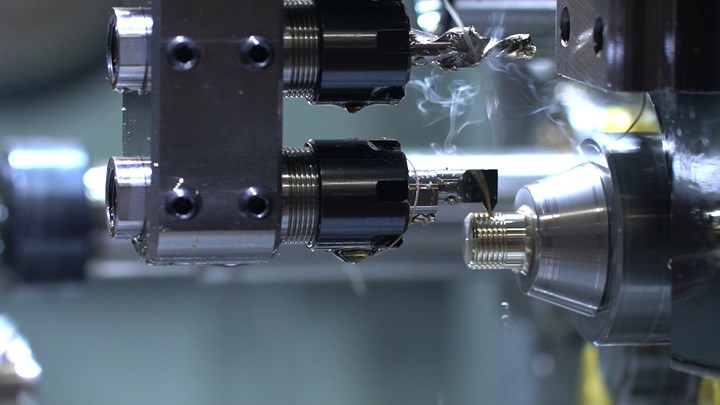

A CNC-programmable, three-station backworking slide enables operations such as single-point turning and threading as well as other operations using standard tooling.

- Three-station backworking axis. This CNC-programmable axis enables operations such as single-point turning, boring and threading, contoured grooving, keyway broaching, drilling and rigid tapping using standard tooling. This is in addition to four independent backworking spindles that offer quick-change tool interfaces for tooling such as drills, spot drills, taps and reamers as well as the capability to perform offline tool length presetting. Collet sizes of ER16, ER20 and ER25 are available for these spindles.

- Servo-driven pickoff spindle. This axis is programmable in 0.0001-inch increments and offers a rapid traverse rate of 1,000 ipm. Pickoff of round, hex and other irregular shapes are possible, and collet closure is pneumatically operated via M codes.

The company believes the Hybrid machine concept should be embraced by those who are used to the traditional Davenport design as well as people more familiar with CNC programming and touchscreen interfaces. Similarly, it feels the machine with fast changeover capabilities can be an alternative to shops currently using other types of equipment for medium-volume production runs, while remaining well suited for high-volume work producing complex parts.

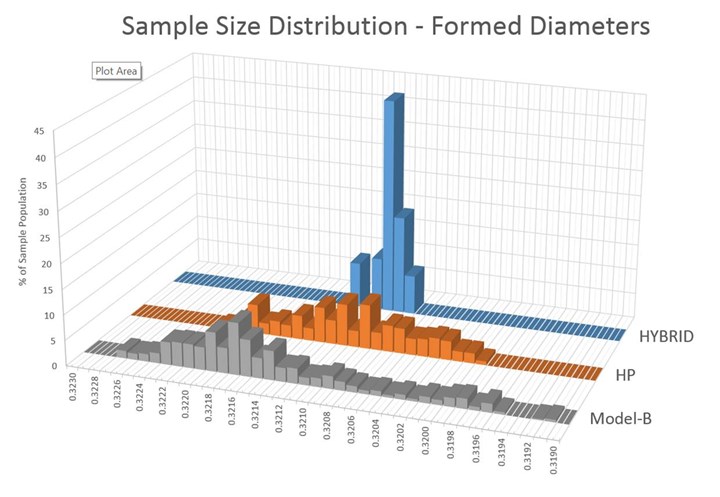

This graph demonstrates the improved process control the Hybrid machine achieves compared to the company’s Model B and HP machines (based on data from a machining test of an identical brass part).

Related Content

Laser Technology "Turns" into a Turning Tool

This new technology uses a laser to act as a cutting tool to "turn" parts from solid barstock. This high-speed precision turning machine is especially useful for micromachining, enabling high accuracy for small, complex parts that are often delicate and difficult to machine when implementing conventional turning processes.

Read MoreSoftware Controls Chip Breaking in Thread Turning Operations

This cutting tool manufacturer has developed a software module for chip control of thread turning operations in virtually any CNC lathe, even for older machines, using specific tooling and software.

Read MoreAutomation Breakthroughs Revolutionize Precision Machining for Complex Parts

Marubeni Citizen-Cincom delivers custom solutions to address some of the biggest challenges in precision machining from handling small parts, to robot integration and unique tooling needs.

Read MoreGetting More Production From Swiss Turning Centers

Buying a new CNC Swiss turning center is a substantial investment. For the best return, look closely for capabilities that enable the best utilization of the machine.

Read MoreRead Next

Davenport: A 10-Year Update

Fooling yourself that the old machine doesn't cost anything except parts is, in my opinion, a mistake.

Read MoreA Tooling Workshop Worth a Visit

Marubeni Citizen-Cincom’s tooling and accessory workshop offers a chance to learn more about ancillary devices that can boost machining efficiency and capability.

Read More

.jpg;maxWidth=300;quality=90)