Workholding, particularly for backworking operations, can be tricky when machining very small parts in a CNC Swiss-type lathe. Depending on their design, pickoff collets can produce a variety of problems, including poor concentricity and runout as well as poor control of clamping force, causing part damage. That is why when Dan Fifer, owner of Lane4 Precision (Santa Rosa, California) discovered collets that worked well for his applications, he became a dedicated customer of the manufacturer and trusted the company’s workholding system with his most delicate and complex parts.

Very small medical workpieces that contain thin walls and require short pickoff lands are often run on Fifer’s five Swiss-type lathes. This complex work requires milling on the subspindle and backworking that is close to the collet. When he originally tried to apply traditional extended-nose collets, the extensions were too long and gaps in the collet were too big to effectively produce his customer’s parts. But then he was introduced to Masa Tool’s Microconic workholding system, which includes collets that are designed without the need for an extended nose because the diameter clearance is already built into the system.

In addition, Fifer says the Microconic collets enable fine adjustment of the collet tension on complex parts. These collets enabled the shop to machine parts it was formerly unable to create with other collets, as well as frequently and effectively perform backworking operations.

From Designer to Job Shop in 1 Month

Microconic collets enable Lane4 Precision to finely adjust collet tension for machining complex parts. In fact, these collets enable the shop to do jobs it was not able to complete prior to implementing this collet system. Photo Credits: Lane4 Precision

Although he quickly learned about the workholding necessary to machine his customers’ parts most efficiently, Fifer did not initially have experience with CNC Swiss-type machining. In fact, when he opened Lane4 Precision in 2017, he had never stood in front of a CNC machine control panel before, let alone a CNC Swiss-type lathe. His background was rooted in design/product development for the medical device industry. After working for several startups for over 20 years, he says he was anxious to be the one to create the parts instead of designing them.

So, he took his passion for innovation and rented a warehouse space where he decided to do all the machining processes in-house. He says someone told him he needed a screw machine to do the work he wanted to accomplish. The timing was good for him to attend IMTS 2016 to shop for a machine tool, and that’s where he met Spinetti Machinery, a distributor that sells Marubeni Citizen-Cincom Swiss-types. He was impressed with the machines’ predictability, and he was confident that the Spinetti team would support him and help him learn how to operate his first Swiss-type, a Citizen L20.

Once this sophisticated machine was set up, an industry colleague asked Fifer if he thought he could make a part that had already been designed. His colleague said no one could build it for him, not because it was not able to be done, but because the colleague did not want to wait 12 weeks to have the order complete.

“I said, well, I have nothing else to do, so I will figure it out,” Fifer says. “So, basically, within a month I was absolutely swamped from a team of about six engineers feeding me more parts that I was able to do.”

With Spinetti’s assistance, he has since selected four more of the Citizen Swiss lathes with different work envelopes and capabilities such as a live B-axis, automatic toolchanger and the machine tool builder’s low frequency vibration technology that helps create small, easily evacuated chips. The distributor was also responsible for introducing Fifer to the Microconic workholding system. A very small part on an L12 was the first job he ran with the workholding system.

Extended Nose Without Extension

Three-quarters of the machining done at Lane4 Precision, which is mostly a prototype shop, is for the medical industry, and the rest are premium parts for the semiconductor, defense, aerospace and consumer products industries, according to Fifer. Parts range in size from fitting within a work envelope of a grain of rice (length or diameter of a half a millimeter or so) to long slender parts over two feet long.

Quickly moving from a designer to a job shop, Fifer never has put his eye for design on the back burner. He considers his niche to be that of helping his customers with design when appropriate. For instance, if he understands a more efficient way to machine something, he volunteers his expertise. “If I can see their design intent, I might say, ‘By the way, you can chamfer this edge, and it won’t cost you anything because I already have the tool’,” he explains. “They might have had two parts I was making that they were welding together.”

Because some parts produced by the shop contain thin walls and have short pickoff lands, it was critical that the workholding system installed offer acceptable tool clearances and fine adjustability for subspindle backworking. The shop also needed compact and reliable over-grip collets for the most complex applications (more about that later). Fifer found his expectations met and then some after installing the Microconic workholding system. In fact, he was so pleased that he eventually added it to all five of his Swiss-types.

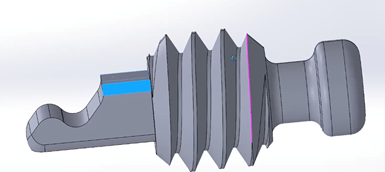

Masa Tool, which only specializes in subspindle collet workholding, has designed the Microconic workholding system which consists of cartridges that are installed in a machine like a standard collet. The cartridge, which offers 0.0002-inch TIR, can be used as a gage to verify machine spindle accuracy. Also, the adjustment dial wrench offers precise and repeatable control of the clamping force, according to the company. Because the cartridge is built with an extended nose, extended nose collets are not necessary, making this system well-suited for Lane4 Precision considering most of its applications require an extended nose pickoff collet. Fifer explains that the Masa collet closure mechanism has been moved right up to the collet nose, improving rigidity relative to standard extended nose collets.

All Masa collets fit into the machine’s cartridge or an adaptor sleeve from the company, making it easy for Fifer to change back and forth between collet styles on all his lathes.

With the ability to easily make fine adjustments to the collet tension, Lane4 can confidently make parts with extremely thin walls without worrying about breaking or distorting parts. Prior to installing the Microconic system, a traditional collet could grip the part too tight and crush it, ruining the part. But making fine adjustments in a controlled, predictable way from the nose of the collet with the provided Masa tool (instead of taking the cover off the subspindle to access the tension adjustment collar) gives the setup machinist easy, precise tension control.

He also points out that it usually takes only 5 minutes when changing over his lathes from machining “large” parts (which for Lane4 are those that are a half-inch diameter and larger) to machining smaller parts when using the Microconic collets. According to Masa, the changeover from a 16C to a 5C collet usually results in a tolerance accumulation and can sometimes take more than 15 minutes to change the collets. But, with the Masa system, once the cartridge is in place, collets can be quickly installed and clamping pressure set right at the spindle nose without tolerance stackup in less than a minute.

Compact Over-Grip

Fifer also appreciates Masa’s over-grip collets for parts that require those. He explains that, although these collets are compact, they offer a large opening and rigid holding. He says they outperform any alternatives he has tried in the past. “My cycle times, rigidity, tooling, everything is better,” he says. “They took away the fear of doing over-grip parts.”

On over-grip collets, extra spread is required to open the collet wide enough to clear the part’s larger diameter. Traditional pickoff collets do not hold to the needed tolerances because they grip short part lengths that only occupy the front section of the collet bore. All the clamping force is on the collet angle, which is a considerable distance from the part being held. As a result, the collet can collapse under the angle.

However, the over-grip collets open up to 0.156-inch diameter larger than the holding diameter. According to Masa, these collets are still capable of 0.0002 inch of TIR. With such reliable gripping, Lane4 Precision has been able to expand its capabilities, even machining some intricate parts “backward,” providing higher quality parts, with fewer defects and a lower scrap rate, enabling operation without interruption.

This part was made on one of Lane4 Precision’s Citizen L20 Swiss-types using a Masa Tool Microconic over-grip collet. The over-grip collet clamped the head of the part to make the milling and threading processes on the machine much easier.

An uninterrupted operation also enables lights-out machining, which is how the machine shop runs several of its jobs using the over-grip collets on Ti 6Al-4V titanium and 316 stainless. He says they have never failed or chipped a tool. “The over-grip collet is a really predictable, consistent run in a production environment.”

Some Surprises

While learning the ins and outs of the Microconic system, Fifer says he realized how much confidence the workholding system’s design has given him to complete high-quality and miniature parts for his customers.

For example, he appreciates that the collet nose is not chamfered. This design leaves more room for pickoff, he explains. “I used to have to face the collet before I could use it, so I could know what I was dealing with. But then it would alter the length of the collet.”

The advantages of excellent runout on the workholding system is another realization Fifer came to after he started putting it to use. It is possible to put very fine features on the backside of a part and maintain concentricity while also producing a “pretty” part. “If you have a 0.005-inch wall and you are trying to put 0.001-inch edge break on it, and you’ve got 0.001 inch of runout, the result is a really ugly part,” Fifer explains. “Using a Masa Microconic collet is like firm footing from the subspindle. At least you know you are starting in a good place for the most critical applications.”

Masa Tool | masatool.com

Lane4 Precision LLC | 707-843-7780

Marubeni Citizen-Cincom Inc. | marucit.com

Related Content

The Value of Auto Adjust Magazine Bar Feeders

This bar feeder is designed to offer the flexibility to enable CNC turning centers to perform short-run work that would otherwise require frequent setups over a range of barstock diameters.

Read MorePMTS 2023 Product Preview: Workholding

Learn about some of the latest workholding solutions that will be on display at PMTS 2023.

Read MoreFixtureworks Clamps Enable Heavy-Duty Machining

Nutrunner clamps are an alternative to hydraulic clamps and provide robotic clamping, automated clamping and unclamping on automated and robotic production lines.

Read MorePrecision Machining Technology Review: October 2024

Production Machining’s October 2024 technology showcase includes some of the latest technology from Ceratizit, Kennametal, Mate Precision Techologies, Horn and Mazak.

Read MoreRead Next

Understanding CNC Collet Chucks

Workholding for turning is usually fairly basic: The selection comes down to chucks or collets. This article looks at when to consider the collet chuck and what kind might be best for a given application.

Read MorePrecision Machining for the Medical Industry

Here’s a machine with the flexibility to provide consistent results on complex, high-value medical parts, working from bar to box with minimal human intervention.

Read MoreA Tooling Workshop Worth a Visit

Marubeni Citizen-Cincom’s tooling and accessory workshop offers a chance to learn more about ancillary devices that can boost machining efficiency and capability.

Read More

.jpg;maxWidth=300;quality=90)