As a maker of precision machined metal parts, how do you describe your shop? Are you a vendor? Are you a manufacturer? Perhaps the most valued machining businesses, those that have established long-standing customer relationships, are problem solvers. These shops can solve a problem for a customer that includes not only manufacturing the part or product agreed upon but also providing additional services that the customer perhaps cannot easily do on its own or would prefer not to do. These value-added services enable customers to concentrate on their core competencies, saving them time and money, while providing the shop with more business and an opportunity to build a long-term relationship with customers.

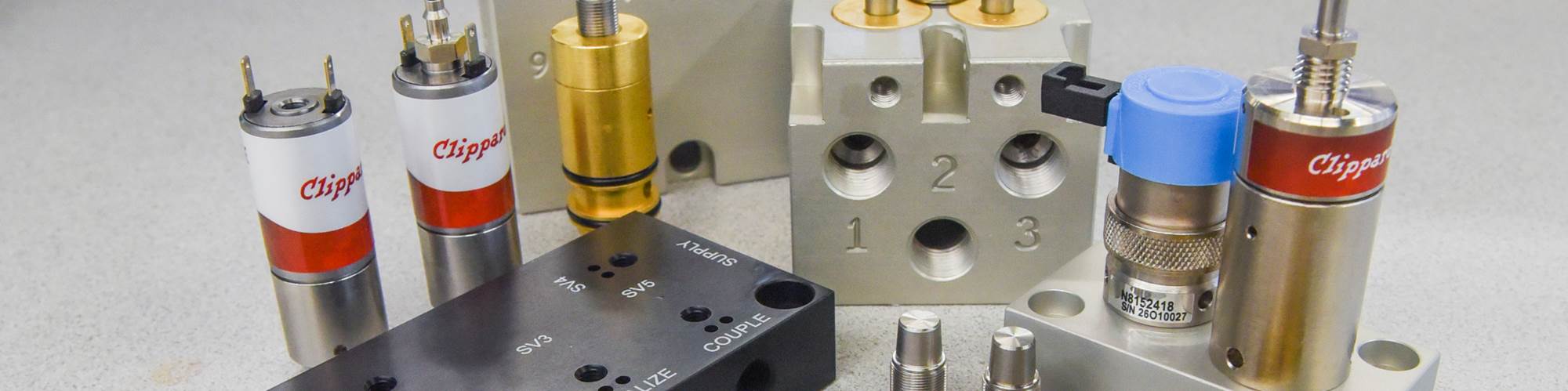

Clippard Instrument Laboratory Inc. in Cincinnati, Ohio, offers value-added services by bringing together its production, engineering and sales staffs to collaborate with customers on designing, building, inspecting, testing and shipping miniature pneumatic assemblies in the time frame required.

“It’s important to us to add an extra benefit for our customers,” says Robin Rutschilling, director of operations. “If we can make a product for a customer but make it simpler for them so they don’t have to worry about things like testing it, then all they have to do is plug-and-play after we send it to them.” He adds that offering value-added services means making a long-term commitment to a customer and the customer making a long-term commitment to Clippard, thus building a strong relationship through the partnership.

Clippard Instrument Laboratory is more than an OEM with a machine shop. The company is a problem solver for its customers, adding value by offering to do what its customers cannot/will not do for themselves.

Clippard, which has manufactured miniature pneumatic components (such as valves and cylinders) since 1941, has a machine shop that includes 12-axis precision CNC Swiss machines, CNC milling centers, CNC turning centers, high production multi-spindle machines, CNC wire EDM technology and numerous post-finishing processes, including thermal deburring.

The company’s machining capabilities have enabled it to develop its value-added department for about eight years, and it’s still growing. Although Rutschilling says the project is only at 25% of where the company would eventually like it to be, it has become a part of its strategic plan and a growth opportunity.

Now, Clippard and its worldwide distributors tout its value-added department and its abilities. However, the first time it did a value-added service the company had not planned for it, according to Rutschilling. “One customer kept sending components back to us claiming our parts were problematic,” he explains. “But then they realized it was their manifold that the parts were installed into that was the problem. That’s when the light went on for us, and we decided to make some manifolds and install our parts in it, send it to this customer and see what they think.” It was a sea change for Clippard when they decided to fix this customer’s problem and present it with the solution. “That’s how we got into the business and how we’ve presented our value-added service since then.”

The appealing aesthetics of the clear, acrylic manifolds that Clippard produces is not the only benefit of using this material. Acrylic enables the company to build a more integrated, lightweight and compact manifold compared with using aluminum, according to Rob Clippard, vice president of sales and marketing at Clippard.

Moving forward, the company has become very good at this sector of the business. It now makes its own testing equipment and has added processes to fulfill value-added services. In fact, machine shops that don’t have their own product line should consider this approach — being a problem solver and not just a shop — to offer higher value to its customers beyond providing parts machined to specification.

Solving Ambiguous Problems

To deliver value-added services, the company treats initial customer interactions as problem/solution sessions: A customer comes to Clippard with a problem, and it comes up with a solution by engineering, designing, prototyping, machining, assembling, testing and then shipping the order as a turnkey product or subassembly.

This wall at Clippard’s headquarters illustrates the many products and applications that the company produces for its customers. Rob Clippard, who began the company’s value-added department, describes a value-added project for medical monitoring, which is used during cardiac surgery. He says Clippard removed much of the assembly work, the fittings and tubings, and a lot of the large parts from the original system and reconfigured the valves and components to reduce its size by almost half. “The ‘value added’ was taking a company’s existing system that they proved out and reducing the size, complexity and manufacturability of the system,” he explains. “We tout a lot that we aren’t just the guys behind the circuit; we can figure things out. We know what it is going to take to make a product. So, we have a manufacturing mindset over a lab mindset.” With this project, the process involved deciding how to make the acrylic manifold in so many steps, adding the components on and then testing the system, especially to ensure its leak-tight specifications were met. Clippard says the challenge of an assembly like this is building an extremely tight overall system, which requires tight tolerances on the manufacturing end.

“Some customers don’t want to do any of the planning and processes required to create a product,” Rutschilling says. “They want to take it out of the box already assembled.” And that is precisely what Clippard delivers to those customers who desire it.

Clippard calls its extra services “value-added” because its customers are getting more than what they would get if they were doing business with a standard machine shop operation that only machines and ships parts. Or, more specifically in Clippard’s case, only providing individual pneumatic components from its extensive product line. But to know what extra processes to offer, the company has learned that listening to customers’ needs and discovering their pain points are keys to building strong partnerships. In fact, getting to know customers well enough to realize what they need before they do is the ultimate strategy for success.

For example, when the value-added department knows that a customer does not have a certain capability in-house or that a process would be very expensive for it to do in its facility, Clippard uses this intel to its benefit. With this information, the company can suggest that customers allow it to do these types of jobs for them as part of its value-added service.

A value-added service can be as simple as loading a gasket to a fitting — something Clippard can do instead of the customer paying someone $12 per hour in its own facility.

But a value-added service does not always have to be related to an assembly. Rutschilling explains that the way a product is packaged might be a value-added service or even a cleaning process. “We’ve added a cleanroom because one customer needed oxygen cleaning to a certain specification,” he says. “We didn’t do that type of cleaning at one time, and we thought, ‘Why aren’t we doing this?’ So, we came up with our own cleanroom, instead of shipping the customer’s parts somewhere else to have them cleaned. Because it is a medical customer, it had to have a clean package, double sealed. So, having a cleanroom gained us much more business.”

Clippard does many subassemblies for customers who might not have the capabilities or interest in doing themselves. By taking care of its own machining and as many value-added services in-house as possible, the company has more control over its own processes.

Smart Solutions

Because the company offers extra services does not mean Clippard does all the processes in-house that are demanded by an order. The company has developed a supplier network over many years that provides high-quality services such as anodizing, electroless nickel plating, precision molding and many others.

For the customers with lower volume needs, Clippard will often suggest solutions using standard products to meet the customers’ requirements. If the project grows to high volume, Clippard can offer a more customized solution using its many value-added capabilities and its proven valve, actuator and pressure control technologies.

Shawn Reitenbach, value-added supervisor at Clippard, is a 25-year veteran with the company who started as an intern in the machine shop. Clippard prides itself on hiring many students from local high school trades programs who gradually move up the ranks within the company, as Reitenbach has. Here, he is holding a special subassembly product that is developed and tested within his value-added department.

At Clippard, the value-added department, which focuses on the company’s special subassembly projects, is supervised by Shawn Reitenbach, a 25-year veteran at the company who started in the machine shop at 17 while enrolled in a local high school trades program.

“When it was time to start this department, we said ‘who do we have that knows how to design fixtures, build testers and understands our products?’ and the list goes on and on,” Rutschilling explains. “And the answer was Shawn. We asked him to start it.”

When Clippard’s engineers have an idea, Reitenbach works with them to test it in the value-added department.

Other processes the department handles include wire crimping, valve stripping and operating a pneumatic ball press to seal holes on manifolds.

The Anatomy of a Service Order

A value-added service order is more complex than a typical service order for a part. Therefore, a lot of communication from both parties is necessary to make a project successful.

Because most of Clippard’s customers are OEMs, they go through a Clippard distributor when the need for a component arises or if they have a new assembly they hope to take to market. So, the distributor and Clippard’s regional sales manager will inspect the application on the customer’s site, then take it to Clippard to present it to the engineering staff.

This automotive hoist controller (top) is being tested in the value-added department for leaking fittings. This manifold and parts that go into it (bottom) to create the hoist controller were manufactured at Clippard.

“Our engineering staff will usually meet with the customer’s engineering staff,” Rutschilling says. “And that's where all the back-and-forth about the design, what we can offer and what they need goes on between engineers.”

At that point, he explains, the customer will often give Clippard a small order — five to 10 pieces — to make prototypes. Once those are created, the customer receives the prototype for testing. “And, if there are any changes that need to be made, it'll come back again to our engineering staff,” he continues. “And then we'll make all our own prototype preliminary parts, do all our own testing and then send them back to the customer again. Once a customer signs off on it to us, the order comes in, which is then turned over to operations.”

Advice for Offering Extras

Although a lot of time and effort is put into every value-added project, Rutschilling believes that any shop can offer customers value-added services, and the process does not need to be complicated. He says anything that benefits the customer that goes above and beyond what an order entails counts as a value-added opportunity.

The company builds its own testers to test the products it manufactures for its customers. This tester found in the value-added department completes flow and decay tests automatically. It has a programmable logic controller (PLC) and is versatile, according to Reitenbach.

Offering customers an expensive process, such as thermal deburring (which Clippard does), that a shop can do for customers for less cost, something they do not like doing, or one that is hard for them to do in their own facilities is a good place to begin.

Starting slow and allowing time to become good at a certain value-added process is also important. From there, continually moving forward and learning from customers will help progression in this area, Rutschilling says. “The key is to network with a supplier (customer) to find out what their pain points are.”

He also advises shops to consider adding services that a customer requests. “Any time you have to send a part outside your company, you no longer have control over it,” he explains. “And, if you add it to your company, you’re going to be more valuable to your customer because they can call you and say, ‘Our schedule just got moved up, so I need that part as quick as possible,’ and you can deliver on that.”

Robin Rutschilling shows Lori Beckman, senior editor at Production Machining, a part the company makes in its machine shop.

Clippard Instrument Laboratory Inc. | 877-245-6247 | clippard.com

Read Next

Clippard Instrument Laboratory Inc.

In 1941, William Leonard Clippard, Jr. founded a company that sold electrical test equipment, magnetic windings and radio frequency coils.

Read MoreVentilator Crisis — Clippard Delivers for Ford

Clippard Instrument Laboratory Inc. in Cincinnati, Ohio, harnessed their talent, experience, capabilities and PMPA network to deliver 50,000 sets of ventilator parts to Ford Motor Company.

Read MoreHow Champions Can Develop a Thriving Workforce

Having a workforce development champion in your shop is more critical now than ever before. Here are five techniques your champion can apply to attract and retain new talent.

Read More