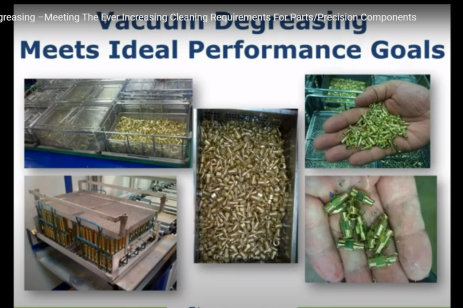

Video: Using Vacuum Degreasing to Reach Parts Cleaning Specifications

Vacuum degreasing offers a low-cost cleaning process that can meet a range of cleanliness specifications for both nonpolar and polar soils, has a low VOC emissions process and excellent rust prevention and protection.

Vacuum degreasing offers a low-cost cleaning process that can meet a range of cleanliness specifications for both nonpolar and polar soils, has a low VOC emissions process and excellent rust prevention and protection, according to this presentation by Chuck Sexton, global product line manager at Kyzen Corp. Sexton describes the latest technology for vacuum degreasing, including chemistry and equipment developments, cleaning performance, and environmental health and safety benefits.

Some other major points the webinar covers:

- Parts cleaning technology trends (at the 2:19 mark)

- Benefits of vacuum degreasing (at the 5:37 mark)

- Vacuum degreasing process overview (at the 9:17 mark)

- Distillation (at the 13:00 mark)

- Polar versus non-polar soils (at the 17:36 mark)

- Why test for acid? (at the 29:03 mark)

.jpg;maxWidth=300;quality=90)