Learn More about Deburring

Deburring is one of those operations that just seems like extra work. The part is complete, but it’s not. It can’t be avoided, so finding more efficient ways to work it into the production process is a common goal.

See new developments in deburring technology at DeburringExpo, October 13 – 15.

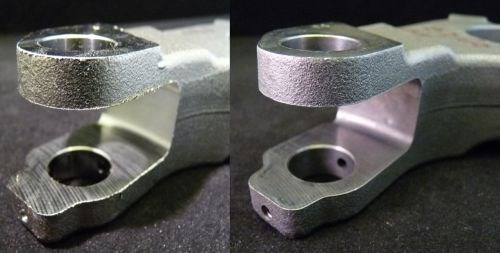

Image Source: ATL

Deburring is one of those operations that just seems like extra work. The part is complete, but it’s not. It can’t be avoided, so finding more efficient ways to work it into the production process is a common goal.

In our e-newsletterInbox InsightsSeptember , Lori Beckman took a closer look at micro deburring, including details about how thermal deburring can simplify the process. Check out “Feel the Heat with Micro Deburring” to learn more.

From October 13 – 15, the first DeburringExpo, a trade show for deburring and polishing technology, will be held in Karlsruhe, Germany. More than 100 exhibitors from eleven countries will be on hand to present products and services for reliable and efficient deburring, rounding and polishing processes that have a substantial effect on manufacturing quality.

At the show, attendees will be able to see a model for predicting and minimizing burrs. This technology is designed to ensure reliable and economically efficient deburring processes. A new process will also be presented that makes it possible to deburr cross-holes with nearly any diameter ratio and with intersection angles of significantly less than 90° in an automated fashion within the machining process with a defined cutter.

Highlights will also include the innovative and easy-to-automate cavitation deburring process by means of which ultrasonically induced cavitation is used for targeted deburring of external and internal component surfaces with minimal energy consumption. The exhibitors will also present new developments in the fields of thermal energy machining (TEM), electrochemical machining (ECM), precision electrochemical machining (PECM), abrasive flow machining, vibratory grinding, brush deburring, and blasting with solid and liquid media.

One of the event’s focal points will cover solutions for the automation of deburring, rounding and polishing processes, in order to significantly enhance their reproducibility and economic efficiency. Measuring technology for process monitoring and quality control are further areas within which the exhibitors at DeburringExpo will present newly developed systems.

.jpg;maxWidth=300;quality=90)