Workforce Development—Training Shows How

To expand on his “Workforce Development—What We Can Do Better” article, Miles Free explains the Who, What, Where, When, Why, How and How Many of one of the four upskilling tools—training.

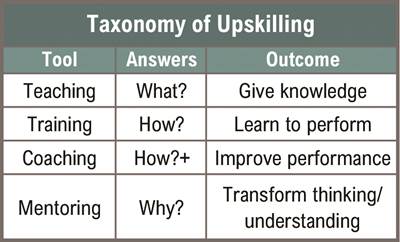

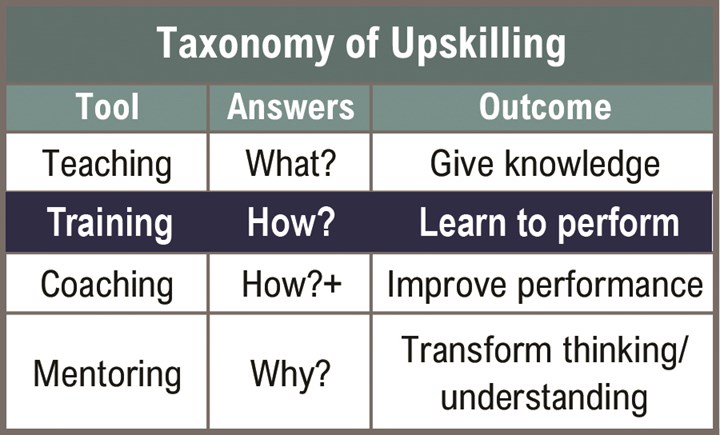

We have four tools that we can use to upskill our employees: teaching, training, coaching and mentoring. Which tool we choose depends on what we are trying to help them accomplish. In this article, we will cover training.

Training is the tool that answers the question “How”—How do I perform this task? The goal in training is to achieve compliant performance to a standard. In our shops, the potential hazards from high voltage, high horsepower, torque, RPMs and sharp tool and workpiece edges also require that we train our performers to avoid hazards and minimize risk of injury to themselves and others. Using the 5W 2H method, let’s examine an approach to training to upskill our shop employees.

Who?

This is not as easy or obvious as you might think. Yes, of course the new trainee is the “Who” However, it doesn’t stop there. Who should do the training? Many times we err by assigning our experts to be the trainer with less than satisfactory results. How many of us have seen a new employee give up and walk out because they couldn’t get the understanding they needed from the expert training them? The expert is so fluent and knowledgeable that in performing they often omit key steps and information that they know, but are not obvious to the trainee. Add a lack of common vocabulary and shop concepts, and the frustration can run high, leading to the “surrender” of the trainee.

I believe that a recently trained, competent employee should be the one providing the training. Because of the recency of their mastering the material, they can still recall the difficulties they had as a novice and are able to place themselves in the trainee’s shoes, better understanding their needs and fears. A process expert can be a resource to validate the training, but in my experience, the most senior experts are often the least effective trainers.

What?

What is the task to be trained? What are the prerequisites for success? What tools, gages, and other equipment will be needed for the trainee to succeed? Limiting the scope of the training is also important, so that the trainee can focus and see their work in the proper context. Collecting job aids, standards and written instructions as well as samples showing the work in various stages help the trainee to see the expected process outcomes. I have found that having reference samples showing acceptable, not acceptable, and marginal qualities can increase the effectiveness of the training.

When?

When is probably taken for granted, but is surely worthy of some thinking. At the end of a shift, when the trainee is fatigued, is probably not the ideal time to try to get them up-to-speed on new tasks. Yes, it is easy to tack on an extra hour or so at the end of the shift, but will that time actually be effective for training? Coming in an hour early is not on most employees list of things that they want to do, but coming in before work will assure a clear mind and no fatigue or performance issues related to prior work. I have found that great coffee helps in this situation.

Where?

Another easy to take-for-granted question is “Where?” Training should be in the area where the work will actually be performed. Yes, it may be quieter in the “training room,” or “break room” but the point of training is performing the task, not listening to a lecture. The actual on-the-job environment has the conditions that the performer will be working in, so training them there ensures that they can perform on the job and not just in a brightly lit, relatively distraction-free break room. Training rooms, I have found, are better for teaching than for training. Train. On. The. Job.

Why?

Why we train is to improve the performance of our employees. However, the purpose of training is not to explain to our people why we do it. The purpose is to train them to perform. Answering the why question is best handled in a mentoring session after they master the actual performance. We train people to perform. Employee performance that meets the identified standards is the desired outcome. Providing the answer to the question “why?” too early actually discourages the learner from learning by doing. It can inhibit their reflecting and self-discovering helpful principles. Yes, adults need to know why. Training is not the time for why. Training is the time for “how.”

The goal of training is to instill in a performer the ability to perform tasks to a standard that meets identified criteria.

How?

How is the payoff for the training. Model the desired behavior. Show which operations in which sequence. Follow the process layout. Demonstrate the standard work. Assure that the bench or work area has what is needed for the task and clear to see. 5-S is easier to demonstrate than to preach. Make sure job aids or checklists are out of the way, but easy to see when needed.

How Many?

How many repetitions are needed to ensure performance? How many trainees can a single trainer train, effectively? How many follow ups are needed to ensure that the training is successful? In the old days, time on task was the gold standard for training, and apprenticeship progress was determined by hours completed, not necessarily by demonstrating competence. In today’s zero defects expectations world, this question must be answered responsibly. Make sure to use professional judgement, understand that all trainees have learning curve issues, and that some tasks are more challenging for some performers. Having poka-yokes or other mistake-proofing methods to ensure that the work product of the performer is suitable for further processing is the gold standard in manufacturing and almost as rare.

Don’t Confuse Training for Teaching

Training is not about verbally conveying intellectual concepts and ideas in a classroom. The goal of training is to instill in a performer the ability to perform tasks to a standard that meets identified criteria. That means demonstrating in the place where the work will be performed. It means providing a method or approach for doing the work that minimizes the chance for failure. It means letting the performer try the task and learn the feel. It means asking them to accept the challenge of doing it themselves, and the feeling of success when they accomplish the job to the standard. Training is not teaching. Training is doing—helping our performers to do it. Do it!

About the Author

Miles Free

Miles Free is the PMPA Director of Industry Research and Technology with over 40 years of experience in the areas of manufacturing, quality and steelmaking. He helps answer “How?” “With what?” and “Really?” Miles’ blog is at pmpaspeakingofprecision.com; email mfree@pmpa.org; website pmpa.org.

Here are more articles from PMPA:

Related Content

Manufacturing Skills Training: Virginia Martinez and Laiken Carrillo

Roles of Women in Manufacturing Series: A precision machining career starts with skills. Virginia and Laiken share their journey and how they help prepare the next generation.

Read MoreCNC Machine Shop Employment Positions to Consider Beyond Machine Operators

Many machine shops have open machine operator positions to fill. But does it make sense for shops to also seek automation engineers, IT managers and assembly personnel?

Read MoreRecognizing Signs of a Degrading Workplace Culture

Is your machine shop missing key “culture elements?” Here are ways to identify if your organization is heading in the right or wrong direction in terms of establishing a healthy company culture.

Read MoreJob Candidate Questions and What They Tell Us

Individuals who ask thoughtful, original questions in the interview set themselves apart.

Read MoreRead Next

Workforce Development: What We Can Do Better

The causes of our workforce issues may be out of our hands, but there are definitely steps we can take to improve our shop’s response to the issue.

Read MoreA Tooling Workshop Worth a Visit

Marubeni Citizen-Cincom’s tooling and accessory workshop offers a chance to learn more about ancillary devices that can boost machining efficiency and capability.

Read MoreDo You Have Single Points of Failure?

Plans need to be in place before a catastrophic event occurs.

Read More

.jpg;maxWidth=300;quality=90)