Automated Enshu VMC Eliminates Idle Time

The part load/unload mechanism is equipped with twin arms for efficient part handling and zero idle time.

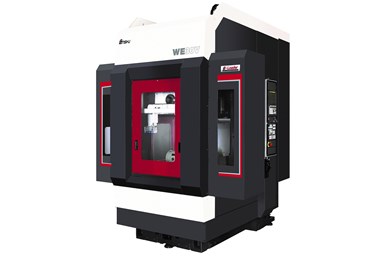

Enshu WE30V machining center

Enshu USA’s WE30V vertical machining center (VMC) comes with an integrated e-loader, which is a built-in automatic part transfer device that is said to provide distinct advantages over the typical external robot, cobot or gantry solution. The WE30V e-loader is a self-contained solution that offers space savings, cost effectiveness and ease of operation, the company says.

The rack and pinion driven e-loader uses a pneumatically actuated, tapered drive pin to engage and drive the part loader along the X-axis motion of the VMC. Located to the right and left of the full X-axis stroke are pick-and-place platforms for part transfer to other machines. The part load/unload mechanism is equipped with twin arms for efficient part handling and minimal idle time. The end-of-arm tooling can be custom designed for applications and has a maximum part weight capacity per arm of 22 lbs.

The WE30V is a BT30 taper VMC with a 12,000-rpm, 7.5-hp direct-drive spindle with rapid traverse rates of 1,968 ipm and a 21-tool ATC magazine. The table size is 25.6" × 15.7" with a weight capacity of 771 lbs. The machine features a FANUC 0iMF control and has been designed with a 200-mm column riser to eliminate any tooling interference that is typically encountered when retrofitting a trunnion-style, five-axis table.

The WE30V e-loader was designed for high-volume, low-mix production environments. Applications include firearms components, medical components and manifold-like workpieces found in automotive and hydraulic/pneumatic industries.

Related Content

-

Unattended Production Takes More Than the Most Capable CNC Machine

Process planning and reliable peripherals are key to successful lights-out manufacturing.

-

Mazak Custom Machining Solutions Feature Automation, Digitalization

IMTS 2024: Mazak features advanced machining solutions designed to boost productivity in automation, multitasking capabilities and machine tool technology.

-

Video Tech Brief: Five-Axis Machining’s Value for the Medical Industry

Watch to see how a medical bone plate is created on a five-axis machining center.