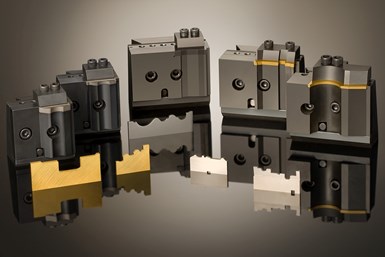

Double-Datum Tooling Carbide Tooling With Interchangeable Components

PMTS 2023: These carbide inserted toolholders are said to reduce downtime with fewer tool changes plus faster tool changeover.

Double-Datum Tooling from Posa-Cut are carbide inserted toolholders with interchangeable components making them well suited for short and long runs. They are said to reduce downtime with fewer tool changes plus faster tool changeover. The design accommodates both radial and axial differences between parts.

A replaceable insert enables users to optimize geometries, grades and coatings, all designed for specific applications. Machine downtime for resharpening is eliminated.

The design works especially well with families of similar parts that are run on the same machine(s). The changeover time between parts can be significantly reduced because the holder base does not need to be removed from the machine. The front plate on the holder base is switched out with one designed for the next part.

The company’s full-service engineering department can design the tooling system for use on many types of machines. The holder base can be made in dovetail, straight shank or circular designs.

Related Content

-

PMTS 2023 Product Preview: Toolholders

Learn about some of the latest toolholder solutions that will be on display at PMTS 2023.

-

Tungaloy Grooving Toolholders Provide Stable Turning

TungHeavyGroove includes an enhanced insert clamping design for maximum tool rigidity.

-

Rego-Fix Through-Coolant System for Swiss-Type Machines

PMTS 2023: The reCool RCR/ERM system provides all the benefits of reCool technology to Swiss-type machines while also enabling the use of emulsion or pure oil coolants.

.png;maxWidth=300;quality=90)