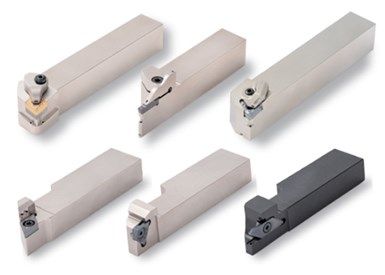

Kyocera JTC Holders Improve Chip Control, Wear Prevention

Inch-size toolholders with high-pressure coolant delivery are designed to improve performance in turning, grooving, cut-off and threading applications.

Kyocera Precision Tools' jet coolant-through (JCT) toolholder series provides multiple high-pressure coolant streams at precise locations, giving manufacturers more chip control and wear prevention for small parts machining. Part of the JCT series tooling lineup includes inch-size holders to improve production with excellent performance in a variety of turning, grooving, cut-off and threading applications. According to the company, the toolholders feature easy connections with a high-pressure hose and joint. The internal coolant provides longer tool life and improved chip control.

Related Content

-

Automation Breakthroughs Revolutionize Precision Machining for Complex Parts

Marubeni Citizen-Cincom delivers custom solutions to address some of the biggest challenges in precision machining from handling small parts, to robot integration and unique tooling needs.

-

Flexible, Quick-Change Tool Adapter System for Live Tools

The system significantly reduces inventory and changeover time for lathe users.

-

ThinBit Angled Toolholders for Swiss Screw Machines

These angled toolholders can position the insert at 30-, 45- or 60-degree angles for reliefs, undercuts and angled OD and face grooves.

.png;maxWidth=970;quality=90)

.png;maxWidth=300;quality=90)