Learning Online

Internet-based training provides a new tool for metalworking managers looking to build the technical knowledge of their employees.

Technical training is so difficult these days. Apprenticeship programs are but a memory in most companies if indeed they ever had them at all. With leaner organizations throughout the manufacturing world, few companies believe they have the time or money to execute a solid in-plant training program today. Although community colleges and local technical schools have gotten better at delivering practical instruction in the last decade, geographic access to quality technical training is spotty at best, particularly to serve continuing education needs. At the same time, the competitive need for a technically proficient workforce grows by the day. That leaves many metalworking companies at a competitive disadvantage, with precious few choices beyond the on-the-job training techniques that have reigned in all too many companies for all too long.

The Internet can have a very significant impact on this situation, however, now that high quality training curriculum is finally making its way to the Web. This is why Production Machining is now working with Tooling University, a company dedicated to addressing the knowledge gap in the metalworking community with comprehensive and affordable online technical training. And so the entire Tooling U program is now available through Production Machining Online.

At this writing, Tooling U includes 40 classes covering the fundamentals of metalworking (see box on page 42), with beginner and intermediate course work in metal cutting processes and equipment, CNC, workholding, materials, metal forming, shop essentials and quality control. Many more classes are currently in development, including new departments on EDM, grinding and welding. Advanced level courses on a variety of topics are in the works as well.

While online training can't replace the hands-on learning that can only come from the shop, it is an excellent alternative to the classroom training that has historically been an essential component of well-balanced technical education. Unlike the classroom, Web-based training can be accessed from almost anywhere and at any time. That lets companies flexibly work training time around production schedules or other time-critical activities. Employees can learn at their own speed, at work or at home—anywhere there is an Internet connection. Moreover, companies can monitor the progress of trainees as they access course work and then confirm their understanding of the material through programmed testing.

How It Works

The content in Tooling U is developed by the company's instructional design team, working in conjunction with a variety of industry sources and experts. The design team creates each class based on a consistently applied methodology for presenting industry knowledge in an "e-learning" environment. Besides applying fundamental principles of learning, the methodology also takes into account the unique nature of the industry content and the metalworking community it serves.

Each class includes learning objectives, a course outline, a de-tailed lesson sequence and a final exam. Students are led through class lessons in a sequential manner so that information is delivered logically and progressively. For example, the 15-lesson "Cutting Processes" class for beginners starts with course Objectives, and then progressively moves through What Is Machining?, The Basics of Cutting Tools, Sawing, Turning, Boring, Threading and Grooving, and then on through other milling and drilling type processes, and finally to broaching. A more advanced course, such as "Cutting Variables," begins by explaining issues related to machinability. It then identifies the specific variables for each of the major metal cutting processes—in the same order as the beginner class—leading to a deeper understanding of feeds, speeds and depth of cut. This common approach to topics, as well as the common look and feel to lessons throughout the program, contributes to easier and quicker understanding by students as they advance from course to course.

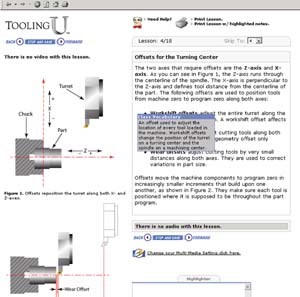

Each lesson in a class includes full text explanations augmented by numerous graphic illustrations. For students who respond better to the spoken word, all text can be delivered in an audio format. Besides pictures and illustrations, many lessons also include video clips, and all are further supplemented with pop-up vocabulary definitions of critical terms. For people with slow Internet connections, video and audio tracks can also be provided on a companion CD-ROM. (Also, Tooling U content, including audio and video, can be downloaded onto a handheld Hewlett-Packard Pocket PC, allowing students literally to take their instruction anywhere.)

If a student has a question about anything in the class, he or she can click on the "Tooling Professor." Here students can post questions to other students on a forum. They can even upload application photos. Tooling U also provides chat room sessions with industry experts and a large industrial resources section with helpful charts, formulas, conversion factors and an industrial dictionary.

Confirmation And Control

Once a student has completed a class, it is time to take the final exam, which will validate how well that student has mastered the material. Upon completing the final exam, students may view the questions and their answers. Incorrect answers are flagged and the correct answers are displayed. Explanations of each question are provided along with links back to the relevant lessons.

Tooling U subscriptions are purchased for a flat annual fee. Subscriptions are obtained on an individual basis (one subscription per person), which gives the subscriber unlimited access to all Tooling U courses for 1 year. In most cases, of course, companies will purchase Tooling U subscriptions for their employees. If so, company supervisors can monitor employees' class progress, schedules and attendance, and can participate by sending messages to their students. Moreover, a company can specify mandatory curriculum, for example, requiring that employees complete prerequisite classes, take pretests, or achieve required performance levels before receiving credit for the class and moving on to the next level.

Course content also can be customized for company, which can be as simple as including the company logo and a corporate message. Or, a company's existing training materials can be captured and converted to a Web-based class that can be accessed individually or in conjunction with complementary Tooling U content. This approach can be particularly useful for training new employees.

A company also can control the testing environment. Some may prefer to test right online. Others may want to have a more supervised testing environment. If so, tests can be printed out and administered with a supervisor present, just like a conventional final exam. Either way, testing provides an objective measure of employee knowledge levels, which can be an extremely useful tool for managers to assess true workforce capabilities. Testing also can be used as a means to objectively assess the knowledge levels of potential new hires.

With this direct connection between testing and instructional course work, metalworking managers finally have a practical means to identify technical knowledge areas needing improvement and to facilitate the necessary learning to achieve their organizational objectives. Such training programs will only grow deeper, broader and more numerous with time. But the time has finally come where virtually any shop can begin to enhance its capabilities by using these tools to build a more knowledgeable workforce.

Related Content

Emerging Leader's Dedication to Education

Instilling confidence throughout a shop floor can do wonders for company morale while increasing productivity.

Read More6 Tips for Training on a Swiss-Type Lathe

There are nuances to training a person to effectively operate a Swiss-type lathe. A shop I visited a while back offers some suggestions.

Read MoreStrengthening Manufacturing Workplaces Through Active Listening

A good strategy to weather the storms of manufacturing market upheavals and unpredictable factors is to commit to continuous, active employee listening.

Read MoreSuccession Planning: Three 15-Minute Activities to Start Preparing for Tomorrow

Succession planning is planning for the future success of your business.

Read MoreRead Next

A Tooling Workshop Worth a Visit

Marubeni Citizen-Cincom’s tooling and accessory workshop offers a chance to learn more about ancillary devices that can boost machining efficiency and capability.

Read MoreDo You Have Single Points of Failure?

Plans need to be in place before a catastrophic event occurs.

Read More5 Aspects of PMTS I Appreciate

The three-day edition of the 2025 Precision Machining Technology Show kicks off at the start of April. I’ll be there, and here are some reasons why.

Read More

.jpg;maxWidth=300;quality=90)