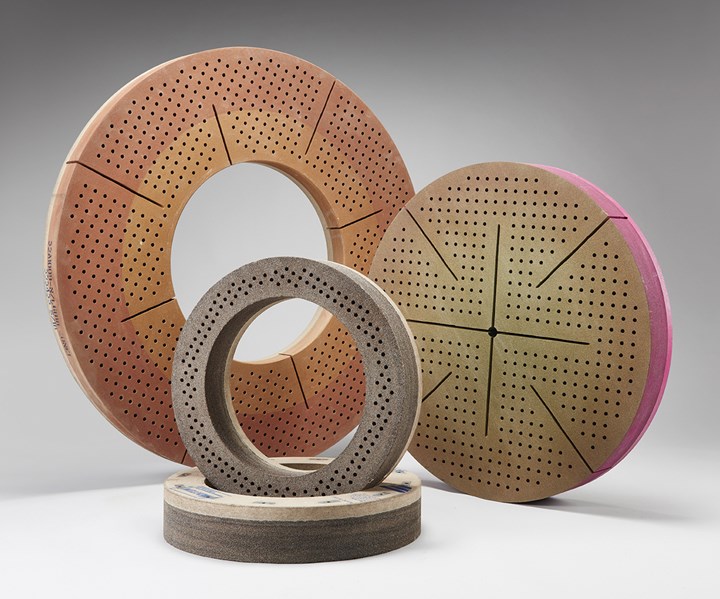

Norton Grinding Wheels Offer Long Life and Consistency

Norton Stellar grinding wheels for double and single disc grinding are suitable for automotive, bearing, tool manufacturing, compressors, knife blades and job shop/ general machining.

Saint-Gobain Abrasives’ Norton Stellar inserted-nut grinding wheels for double and single disc grinding offer improved wheel life, increased parts per wheel and lower cost per part, according to the company. The wheels are suitable for a range of industries including automotive, bearing, tool manufacturing, compressors, knife blades and job shop/ general machining.

Wheels are available in Norton's range of grains and bonds, are made-to-order to fit exact customer requirements and are available in diameters from 8" through 42" and in grit ranges from 16 through 220.

Related Content

-

Studer S100 Grinding Machine For High-Precision, Flexible, Reliable Grinding

The machine is well suited for a wide range of internal, surface and external grinding applications, making it well suited for the entry-level market.

-

Should You Bring Tool Regrinding In-House?

In some situations, the potentially high investment in an in-house tool grinding process can be justified with a relatively fast ROI. (Includes video.)

-

Grinding Options for Dental Burrs and Rotary Instruments

Equipment to grind dental burrs continues to evolve. Here are five options for grinding these types of workpieces.