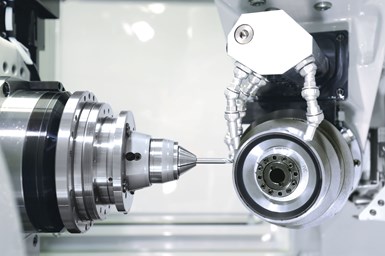

The investment in an in-house tool regrinding process can be significant, but can pay off in the long run depending on a shop’s tool consumption. (Photo credits: ANCA except where noted)

The cutting tool regrinding industry is experiencing change. Regrinding — or resharpening of high-performance tools and drills — is a cost-effective and environmentally friendly solution for extending tool life. Resharpening is offered by tool service providers across a wide range of manufacturing industries, including aerospace, automotive, medical, power generation and woodworking.

CNC tool grinders such as those offered by ANCA are traditionally sold to cutting tool manufacturers and regrinding services, which constitute the largest share of the market. However, in-house CNC tool grinding has become increasingly attractive to machine shops and manufacturers that consume a sizable volume of tools.

Resharpening is driven by both environmental responsibility and the need to reduce overall tooling cost. The cost to recondition tools is generally lower than replacing them, and it is commonly understood that the resharpening process is typically less than half the cost of producing a new tool. When you consider that a typical end mill can at minimum be reground three times, the numbers become even more compelling.

When considering adding regrinding, the cost of the operator will come into the equation based on the number of shifts over which the machine will run and if the machine has the automation capabilities to run unattended.

Tool service providers generally offer a precise, high-quality resharpened tool and aim to deliver performance near to the original tool manufacturers’ specifications. But, when does it become more attractive to in-source tool resharpening, and not only from a cost perspective?

A large tool consumer can potentially save significant costs by bringing reconditioning in-house. An added bonus is the flexibility that comes with reduced turnaround time. Therefore, it’s not just the cost of the tools that should be considered, but also the potential loss of production if the right tool isn’t available when it’s needed. In addition, shops won’t need to carry excess inventory as a means for back-up.

Although today’s CNC tool grinders are intuitive to use, tools have become more complex. While ANCA has introduced technology to readily automate mixed-batch regrinding to help ensure the process is easy and effective, any company new to tool grinding still must establish in-house expertise.

In any case, it’s a big step. That’s not only because the investment in a tool and cutter grinder can easily be $300,000, but there’s also the cost of grinding wheels, workholding, coolant, utilities, floor space and, of course, the operator. A suitable CNC tool measuring machine also will add to the overall expense.

While an in-house tool grinding machine provides freedom to produce quickly and improve effectiveness in new ways, a machine shop that considers adding in-house tool grinding typically faces a difficult investment decision. As a result, the cost of outsourcing and the investment of bringing tool regrinding in-house needs to be compared on a case-by-case basis.

How to Approach the Business Case

The cost of regrinding in-house will depend on the use of a tool grinder. To approach the question in an objective way means first determining the hourly rate of the investment. This includes the cost of depreciation, interest, floor space, energy, maintenance and consumables. The cost of the operator will come into the equation based on the number of shifts over which the machine will run and if the machine has the automation capabilities to run unattended. Based on the hourly rate and the estimation of cycle time per tool that’s reground, a shop will be able to compare the base cost of in-house resharpening opposed to outsourced services.

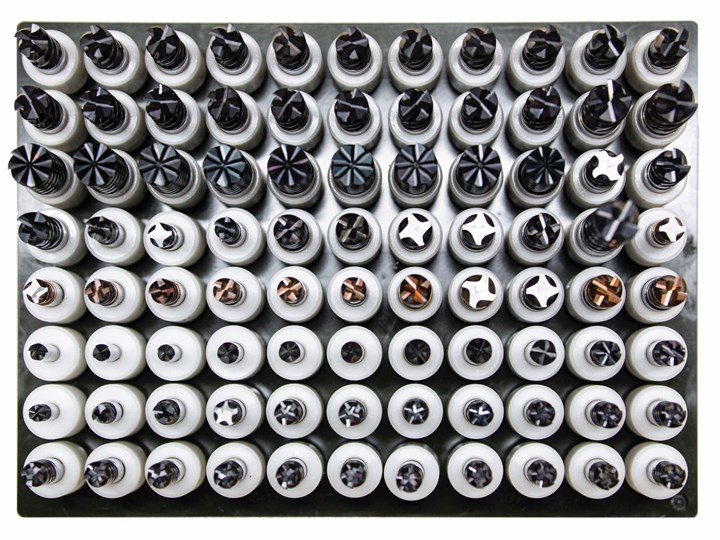

Pallet strips can enable shops to group their cutting tools by size to improve the effectiveness of robotic loaders.

Once a shop has a cost comparison, it will be important to also evaluate “soft factors” such as:

- Tool quality;

- Cost of spares to maintain production while tools are reground;

- Outsourced resharpening cost per tool times the number of spindles needed in the machine shop;

- Turnaround times/waiting times and possible cost of lost production in the event of a delay in regrinding service;

- Other processes required like edge preparation or coating; and

- Service and shipping costs.

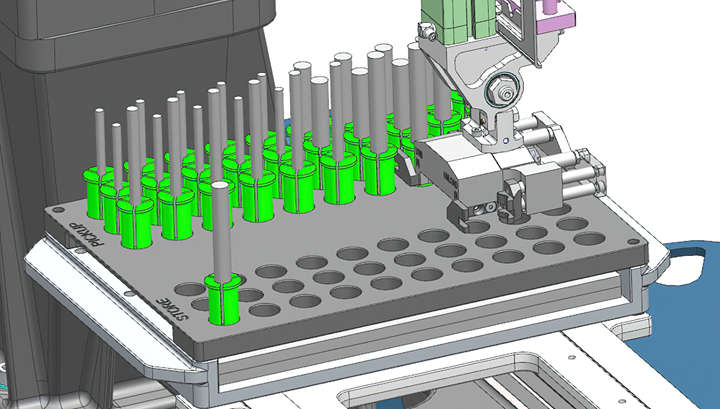

Don’t Forget Tool Measurement

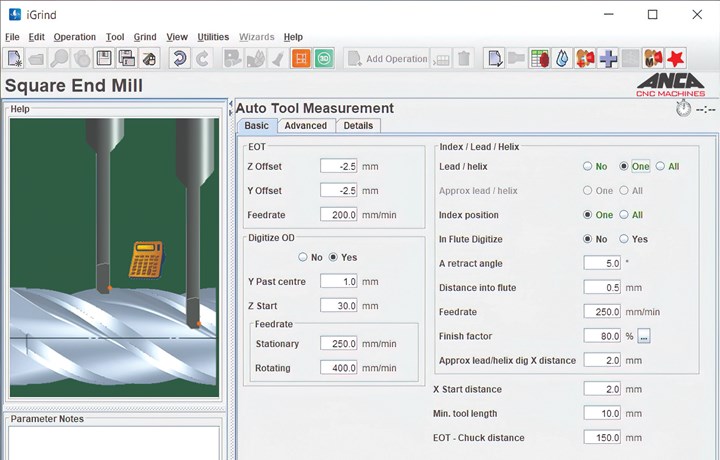

ANCA also pairs with industry partners such as Zoller, which offers tool presetting, measurement, management and software to provide integrated regrinding solutions. For example, ANCA and Zoller have developed reliable data transfer to automatically pre-set the regrinding process, which includes the wear of the tool measured. The regrinding parameters can then be allocated to a corresponding pallet location when a tool loader is used. Once the tool is picked up by the loader and presented to the workholding unit, ANCA Auto Tool Measurement (ATM) digitizes the tool. The ATM cycle measures the most commonly required parameters for almost all tool types, meaning a mixed batch of tools can automatically be loaded and reground.

This automation solution uses collets with the same outer diameters to simplify robotic loading of tools having different diameters.

ANCA Loadermate software can group the tools by tool type, required regrinding operations and infeeds based on the wear factor. The Loadermate allocation sets up a mixed batch of tools for unmanned operation. ANCA also offers a variety of automated regrinding solutions for mixed batches, such as collet loading (when tool and collet are getting changed together) or collet changing and radio frequency identification (RFID). With RFID, the required information is recorded at a programming station and the tool is coupled with the RFID tag. The machine picks up the tool together with the RFID tag, scans the RFID tag and automatically calls up the grinding program. The RFID is parked while the tool gets loaded and reground.

With the ANCA RFID solution, shops can randomly load tools into a loader pallet by creating an individual program for each tool. The tool position inside the pallet can be swapped with another tool any time a tool needs to be reground in a hurry. The tool and cutter grinders can run the regrinding operation individually and unmanned, and the duration of unmanned machine usage depends on the type of loader and the capacity of pallets.

Case Study: Tool Regrinding at GKN

Clearly, it’s a big decision whether or not to bring tool regrinding in-house. In fact, it’s a question GKN Aerospace Engine faced. But ultimately, cost savings by bringing tool regrinding in-house lead to a two-year payback. (See video at the bottom of the page.)

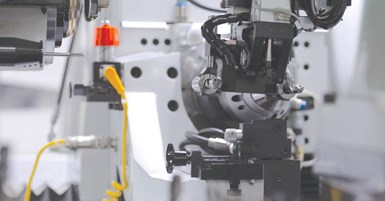

Automated CNC tool grinding can simplify the integration process for equipment with which some shops might not be familiar.

Given the necessary investment, GKN’s management asked Principal Manufacturing Engineer Jeremy St. Pierre to study its tool consumption and project the potential savings bringing tool grinding in-house. One key factor St. Pierre noted was that many of its tools can be reground multiple times. For example, he pointed to many tapered ball nose end mills, which can be resharpened to the desired true form. Conversely, many tools are complex, having unequal indexing and variable helices. Many outside vendors often don’t want to regrind these tools unless they made them originally. So if it’s not possible for a shop to regrind tools itself, it becomes locked into a limited supply, which is a costly and potentially risky place to be.

St. Pierre also found that some of GKN’s high-volume tools were very expensive just because they were not standard in the industry. “Instead of having a half-inch cutter, we might have a 0.485-inch cutter diameter,” he explains. “Because that technically is a custom, we were paying a premium and ordering 12 weeks of tooling. And we had long lead times.” By calculating its true cost of tooling, including the frequency with which it had to “send out 70 tools at once to get a good price,” St. Pierre was able to make a strong case for investing in an even more capable tool room than originally envisioned. This included four ANCA MX7 Linear tool grinders, an automated Zoller Titan measuring machine and a full complement of support equipment, such as a wheel dresser and a drag finisher.

Automatic tool measurement can reduce the time needed to program tool paths and enable users to implement further automation systems to great effect.

St. Pierre’s tool room attached to GKN’s aerospace engine plant in Newington, Connecticut, now services all seven GKN aerospace engine sites in North America. It significantly improves GKN’s overall efficiency simply by delivering the tools the production floor needs quickly. This tool room also serves as a separate profit center. It sells to other local aerospace companies and has been able to bring in outside work for other companies to add revenue.

One surprising discovery St. Pierre notes is being able to eliminate the need for coatings on many of the company’s tools by instead honing the cutting edge in an OTEC drag finishing machine. “Our tools are lasting longer edge-prepped than they were coated,” St. Pierre says. “We do coat many of our tools if they’re being used for high-temp machining, but we make a lot of tapered balls for titanium and we’ve done a lot of testing. We just edge prep a tool and it lasts. Sometimes we’ve had four times the life of previous tools.”

He says in addition to the higher performance, edge prepping also eliminates the roughly one-week lead time required for coating, plus that cost and the extra shipping and handling. “A regrind might cost $5 or $100,” St. Pierre explains. “But if it’s a $5 regrind, it’s still a $10 coating. Now you’re basically at three times the tool cost. We can eliminate that with a process that takes a few seconds.” (GKN’s average honing time is approximately one minute, and the OTEC processes 25 tools at a time.)

For GKN Aerospace Engines, cost savings by bringing regrinding in-house led to a fast, two-year payback. (Photo credit: Zoller)

It’s worth noting that although St. Pierre had years of manufacturing and problem-solving experience when he started the project at GKN, he’d never ground a tool. That also holds true for everyone who joined the team thereafter. “I hired people who I knew were mechanically inclined and understood the real world and how you shouldn’t overcomplicate things,” St. Pierre says. “They were all nervous at first, but the first thing we did was fly to Michigan for two weeks of training with ANCA, and then we started running.” They’ve been learning ever since, and made some mistakes, he adds. But only once have they sent out a tool that failed.

Consider the Measuring Machine

Arguably the second most important investment decision for a tool room, especially one serving an aerospace company, is the inspection equipment. Zoller was a natural fit first because GKN already had Zoller presetters, and St. Pierre appreciated the smooth working relationship they’d established. Also, Zoller has a close partnership with ANCA, resulting in solutions that make both machines more capable. So, GKN opted for a Zoller Titan which can automatically measure every tool attribute optically, including the flute form and the edge prep.

GKN’s Zoller Titan tool measuring machine has a Roboset2 loader to enable long stretches of unattended operation. (Photo credit: Zoller)

The Titan also has a Roboset2 loader, and GKN also opted to add robot loaders to each ANCA MX7 tool grinder in addition to internal wheel dressing and measuring. The machines also have an integrated laser that can scan a tool profile and automatically compensate the grinding program to correct for any deviations from the nominal form. These combined features enable the machines to produce tight-tolerance tools throughout an unattended shift. “We hold ourselves to plus nothing and minus a half thou on our tools and a tighter tolerance on some tools,” St. Pierre says. “If it’s a ball nose for finish machining, we’ll hold a couple of tenths.”

All robotic systems use Schunk hydraulic chucks that clamp different diameters with the insertion of an intermediate sleeve. In GKN’s case, a robot changes out the sleeve. As St. Pierre notes, the RoboSet2 and MX7 loader have all the sleeves already inside and knows where they are. “Let’s say batch number one is a half-inch tool,” he explains. “The robot will grab the half-inch sleeve and load it into the chuck. Then it will run all those half-inch tools and perform the required reporting. Once that’s done, it’ll swap sleeves, grab the next size tool and then start running that program. You just have to write the program and select your schedule.” GKN customized its pallets to hold five different sizes, and St. Pierre says that they can run 20 different tool designs through the Zoller unit in one unattended shift.

Other Ancillary Equipment

Any tool grind shop also needs coolant filtration and temperature control, which at GKN is handled by double vessel Transor systems. Cut-off machines are also handy for sizing carbide blanks. Instead, GKN took a creative approach and opted for a Makino U6 wire EDM unit. St. Pierre explains that the price difference wasn’t significant enough to justify spending that much on a machine that can only cut off. “So, we bought a wire EDM to do custom cut-offs in large batches. We also make our own fixturing and inspection gauges for the whole company. That machine paid for itself the first year making things that aren’t related to grinding tools.”

St. Pierre says GKN also uses wire EDM to cut tool profiles and then grind the flute and OD in the ANCA machines, as well as make steadyrest bushings for the them.

Finally, Zoller’s TMS tool management software, a 3D printer for robot grippers and other tooling, a Modula VLM storage tower and a laser marker rounds out GKN’s efficient, self-sufficient tool room.

For GKN, bringing regrinding in-house was lot of work and a big investment. But, as St. Pierre summarizes it, “No one’s looking at this project saying it was a bad investment. Everyone says they wish we had done this earlier.”

About the author: Lucas Hale is the global marketing manager at ANCA CNC Machines, having more than 20 years’ experience in robotics, machinery and automation.

Related Content

Carbon Fiber Spindles Aim to Eliminate Grinding Variance

These spindles available on Tschudin CNC centerless grinders are designed to minimize the heat transfer factor while optimizing dimensional stability and material removal rate.

Read MoreThe Advantages of Turning and Grinding on One Machine Platform

Instead of using a dedicated grinding machine or an outside grinding vendor to achieve very high surface finishes, a machine that can hard turn and grind can reduce WIP and speed part completion while taking up minimal floor space.

Read MoreANCA Grinding Platform Boosts Tool Grinding Productivity

The MX7 platform supports the grinding of various tool shapes in a single setup, eliminating the need for wheel changes.

Read MoreStuder S100 Grinding Machine For High-Precision, Flexible, Reliable Grinding

The machine is well suited for a wide range of internal, surface and external grinding applications, making it well suited for the entry-level market.

Read MoreRead Next

Emerging Leaders Nominations Now Open

Here’s your chance to highlight a young person in your manufacturing business who is on the path to be a future leader moving your company forward.

Read MoreA Tooling Workshop Worth a Visit

Marubeni Citizen-Cincom’s tooling and accessory workshop offers a chance to learn more about ancillary devices that can boost machining efficiency and capability.

Read MoreDo You Have Single Points of Failure?

Plans need to be in place before a catastrophic event occurs.

Read More

.jpg;maxWidth=300;quality=90)