The Advantages of Turning and Grinding on One Machine Platform

Instead of using a dedicated grinding machine or an outside grinding vendor to achieve very high surface finishes, a machine that can hard turn and grind can reduce WIP and speed part completion while taking up minimal floor space.

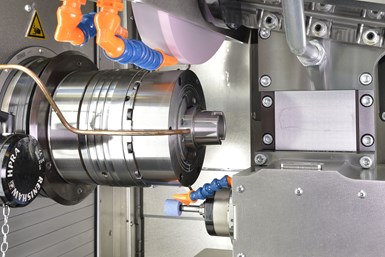

The external, water-cooled grinding spindle shown at the top is oriented at a fixed 12 degrees to the workpiece spindle to enable angular, in-feed grinding and end-face machining with peripheral grinding. Photo Credits: Spinner USA

The term “multitasking” when describing machining equipment can mean different things to different people and even different machine tool manufacturers.

When it comes to Spinner USA’s Microturn Grind, it means soft turning, hard turning, milling, drilling and internal and external grinding on one machine platform. Among other advantages, the company says this saves floor space and eliminates the cost of a dedicated grinding machine(s) as well as minimizes work in process (WIP) because parts can be machined complete.

The Microturn Grind’s 12-station turret with Y axis can access both spindles to perform soft or hard turning as well as milling and drilling. The turret’s BMT45 tool interface is said to provide high stiffness and all the 12 turret positions are driven tool stations to create features such as keyways and contoured features. Hard turning of workpieces to 60 HRC performed on the same machine minimizes the amount of stock to be removed by grinding or, in some applications, can eliminate grinding altogether.

Both main and subspindles are identical and offer speeds as high as 10,000 rpm. (The machine is also available with only a main spindle.) Touch probes can be mounted in the turret to enable in-machine measurement of internal and external workpiece features for automatic process control, tooling offset adjustments and determining workpiece position prior to machining.

The Microturn Grind features two stations with internal grinding spindles programmable to 90,000 rpm. These stations can be configured such that one faces the main spindle and the other the subspindle, or both can face the same spindle depending on a shop’s needs.

The external, water-cooled grinding spindle is oriented at a fixed 12 degrees to the workpiece spindle to enable angular, in-feed grinding and end-face machining with peripheral grinding. Having a maximum wheel diameter of 400 mm, it is said to provide the capability to provide material removal rates and wheel life of dedicated cylindrical grinding machines achieving speeds as high as 4,000 rpm. C-axis interpolation enables the machine to grind non-round polygonal shapes at creep speed.

The Microturn Grind features two stations with internal grinding spindles programmable to 90,000 rpm. These stations can be configured such that one faces the main spindle and the other the subspindle, or both can face the same spindle depending on a shop’s needs. Diamond dressing units for the internal and external grinding wheels are mounted on the main and subspindle housings.

To enable unattended machining, a number of automation options are available, including bar feeders, pallet changers and custom automation solutions through Spinner-Automation GmbH.

Related Content

-

Carbon Fiber Spindles Aim to Eliminate Grinding Variance

These spindles available on Tschudin CNC centerless grinders are designed to minimize the heat transfer factor while optimizing dimensional stability and material removal rate.

-

Lissmac Grinding Machine Provides Versatile Surface Finishing Performance

The EBSC grinding machine is capable of processing both tri-dimensional and flat parts, allowing for broader applications across various industries.

-

Grinding Options for Dental Burrs and Rotary Instruments

Equipment to grind dental burrs continues to evolve. Here are five options for grinding these types of workpieces.

.jpg;maxWidth=300;quality=90)