Vardex Threading Toolholders Offer Two Coolant Ports

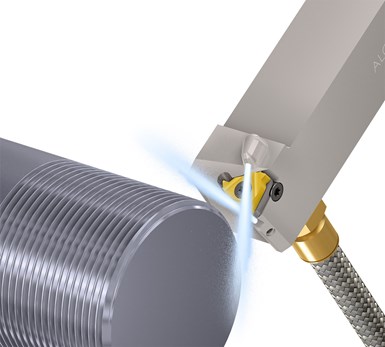

Vardex external thread turning toolholders have two high-pressure coolant outlets for greater precision and longer tool life.

Vargus USA’s ALCN line of external thread turning toolholders feature two precise, high-pressure coolant outlets designed to cool the top and bottom of the insert for longer tool life, and are specially manufactured for high-pressure coolant (up to 70 Bar). According to the company, when used with a quality coolant, the cutting-edge temperature is dramatically reduced, thereby increasing tool life. Also, the through-coolant capability improves chip evacuation for better chip control and flow, and enhanced productivity.

The new toolholders also feature three coolant inlets, suitable for some of the most popular machines on the market, including a bottom inlet designed for standard screw connection;

a bottom inlet specially designed for VDI Holder according DIN 69880/ISO 10889; and a back inlet designed for standard screw connection. The toolholders are available for Vardex standard lay-down insert sizes: 3/8", 1/2" and 5/8", and are offered in metric and inch shanks. Additionally, the new range also offers left hand toolholders as standard. All new toolholders are nickel-coated for better wear resistance and anti-corrosion protection. The new toolholders are integrated into the Vargus Genius software for tool selection and accessing suggested cutting data.

Related Content

-

Rego-Fix Through-Coolant System for Swiss-Type Machines

PMTS 2023: The reCool RCR/ERM system provides all the benefits of reCool technology to Swiss-type machines while also enabling the use of emulsion or pure oil coolants.

-

Tips for Choosing the Right Toolholder for High-Speed Machining

Here is some advice for shops hoping to maximize their efficiency performing high-speed milling operations.

-

Machining’s Impact on Sustainability

Individual elements of the machining process such as machine tools, tooling and even CAD/CAM software play a role in overall machine shop sustainability. Observing the entire process especially when it comes to their influences on energy usage is key.

.png;maxWidth=970;quality=90)

.png;maxWidth=300;quality=90)