Medical

Filling Bins While the Building is Empty

Over the past decade, technology has advanced to the point that lights-out machining is more seamless than ever before, with built-in safety systems and even the ability to switch from one part to another in the middle of the night.

Read MoreFDA Releases Draft Guidance for Additive Manufacturing of Medical Devices

Even if additive manufacturing and medical devices are not yet on your radar, this information may be useful in strategic planning for cleaning complex parts.

Read MoreUpdate: FDA Releases Draft Guidance for Additive Manufacturing of Medical Devices

The benefits of AM may result in cleaning challenges. The layer-by-layer process of AM allows complex internal support structures and tortuous internal channels.

Read MoreProcess Control in the Medical Shop

For this shop, successful delivery of medical and dental components is about proper process and machine tools that can handle the job.

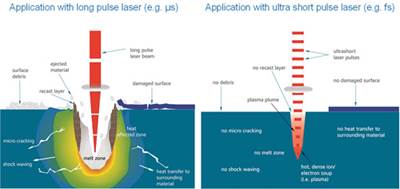

Read MoreFemtosecond Laser Processing in the Medical Device Industry

Recent advances in the laser technology have brought improved capabilities for precision machining—no thermal effects and minimal post processing.

Read MoreMedical Machining is in the Genes

Sometimes it’s difficult to stay away. This company is an example of a precision machining family that simply can’t stop doing what it does.

Read MoreManufacturing Medical Devices for Today and Tomorrow

The pace of change in medical device design and manufacturing is rapid and is fueling demand for machine tool capability that not only reduces cost per piece today, but can open doors to producing new types of parts in the future.

Read MoreTooling Up for Micromachining

Choosing the right tools and matching them to the correct operations and process techniques for micromachining applications is critical to success in this burgeoning market.

Read MoreSingle Pass Honing System with Automatic Tool Wear Compensation

Single pass honing, also referred to as diamond bore sizing, is a good way to produce parts economically when the bore is small or has thin-walled members that need to be honed.

Read MoreSwitching Material Improves Productivity, Bar None

Serving the exacting and specialized requirements of the medical implant industry requires manufacturers to not only use the most precise, state-of-the-art metalworking equipment, but also high quality raw materials, including precision ground bar capable of offering tight dimensional tolerances and exceptional diameter uniformity.

Read More

.jpg;maxWidth=300;quality=90)