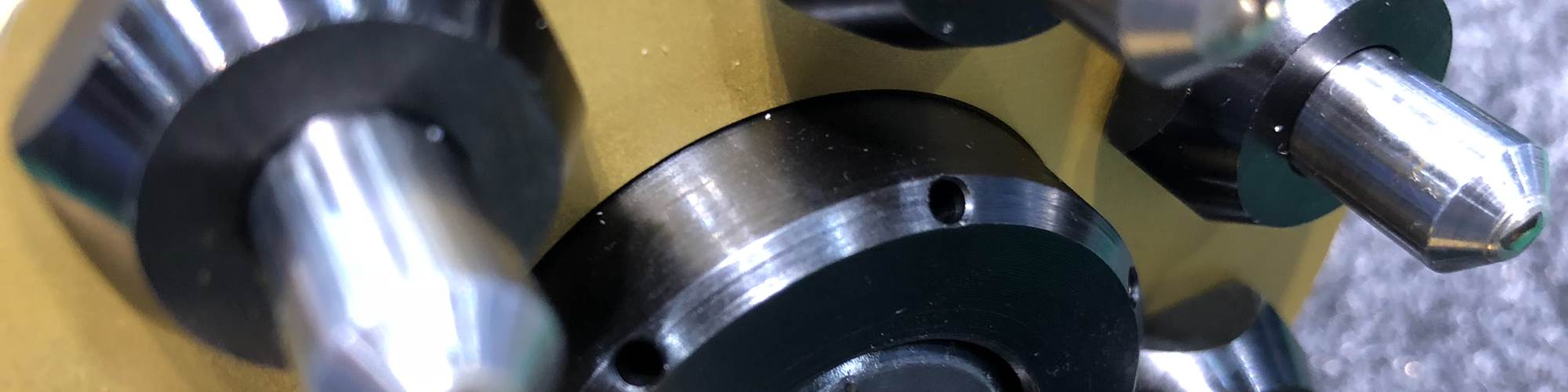

This diamond-tip burnishing tool installs in a machine tool and achieves surface finishes down to 4 microinch Ra, depending on the material.

When you think of a burnishing operation, likely roller burnishing of the inner or outer diameters of cylindrical parts comes to mind. But, it’s also possible to burnish large flat surfaces on a VMC or HMC.

Roller burnishing is a method of producing an accurately sized, finely finished and densely compacted surface that resists wear. Hardened and highly polished steel rollers are brought into pressure contact with a softer workpiece. As the pressure exceeds the yield point of the workpiece material, the material surface is plastically deformed. Peaks on the machined surface are caused to cold flow into the surface valleys, creating a plateau-like profile in which sharpness is reduced or eliminated in the contact plane. The burnished surface will, therefore, likely resist wear better than an abraded surface in metal-to-metal contact, as when a shaft is rotating in a bushing. Though almost any metal can be successfully roller burnished, ductile or malleable metals are best.

Cogsdill Tool Products offers such roller burnishing tools as well as single-point diamond burnishing tools that install in the tool post or turret of Swiss-type lathes and conventional turning centers where space can be limited. The tool’s spring-loaded nib with diamond tip is brought into contact with the workpiece at the centerline of the part and perpendicular to the surface being finished. The tool is then fed into the workpiece an additional 0.002 or 0.003 inch to enable the diamond insert to become disengaged from the stop in the holder. The spring, with its preload, forces the diamond against the workpiece. The tool is then fed along the surface of the rotating workpiece to produce a mirror-like finish.

While the tool must be used with coolant, no special coolant is required. Straight oils, soluble oils and synthetic coolants can be used to provide the necessary lubrication. The company says that, with most metals, a turned or ground part with a properly prepared 40 to 60 microinch Ra finish can be burnished to a 4 to 8 microinch Ra finish in seconds. Cast iron can usually be burnished to an 8 to 15 microinch Ra finish.

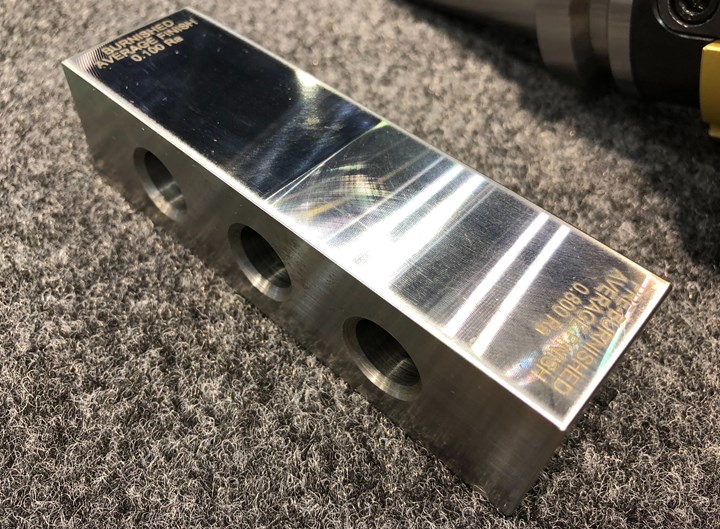

Diamond inserts cold-flow material peaks into valleys in one pass, producing mirror-like finishes on flat surfaces.

In fact, Cogsdill applies this diamond-tip burnishing concept to a face mill tool used to burnish large, flat, milled surfaces. Typically, for these flat surfaces, manual hand polishing or lapping is required to remove cutter witness marks and improve the finish. Results depend on people’s skill levels and such tasks can prevent them from performing other, more value-adding duties. The diamond burnish face mill tool from Cogsdill installs in the spindle of a CNC machining center to enable it to perform a burnishing operation after machining. The tool can achieve surface finishes down to 4 microinch Ra, depending on the material.

CNC machining leaves behind witness marks that might be undesirable, depending on the application. On-machine burnishing eliminates manual polishing or lapping.

These rotating tools use multiple, spring-loaded nibs with diamond tips that cold-flow material peaks into valleys in one pass, leaving mirror-like finishes on the surfaces of most metals. These tools feature through-coolant delivery and can be used with any type of coolant. In operation, the nibs are brought into contact with the workpiece perpendicular to the surface being finished. The tool is then fed down into the workpiece an additional 0.002 to 0.003 inch (like the single-point tool version) to enable the diamond tip in each nib to disengage from stops and contact the material surface. The rotating tool then traverses the top of the part and completes the burnishing operation (multiple passes are required when the part surface is wider than the tool). The tool can also be used for interrupted-cut applications, such as the face of a flange with a keyway or multiple bolt holes. Spare diamond inserts are said to be easily replaced and available from stock. According to the company, achieving a uniform burnished finish requires a part surface flatness deviation of no more than 0.002 inch to keep the nibs’ preset spring load consistent.

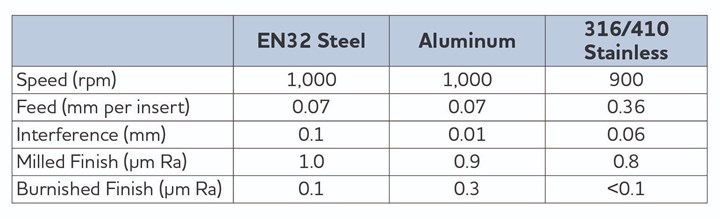

Table 1 shows results from tests Cogsdill has performed burnishing EN32 case-hardened steel, aluminum and 316 and 410 stainless steel. Tools are available in diameters of 63, 80, 100 and 125 mm, and their number of nibs are 5, 7, 9 and 11, respectively. The tools are offered in standard face mill arbor sizes.

Table 1. Diamond burnishing test data.

Related Content

Shop Sets its Sights on Precise Tool Alignment

A Wisconsin shop has found that visual tool alignment technology has improved tool life and surface finishes for its Swiss-type lathes while increasing throughput as well.

Read MoreCNC Turning Tips for HRSA Materials

Rough-turning, heat-resistant superalloys can be challenging. However, new carbide insert technology provides the capability to perform high-speed, high-feed roughing in a single pass.

Read MoreTool Path Improves Chip Management for Swiss-Type Lathes

This simple change to a Swiss-type turning machine’s tool path can dramatically improve its ability to manage chips.

Read MoreParting Off: The Case for Standardizing on Sawing

The value of rotary saw cutting for parting off operations could boil down to simple economics paired with process efficiency gains.

Read MoreRead Next

Cogsdill Tools Designed for Use in Limited Space

Cogsdill Tool’s Micro-Roller Burnishing Tool series is designed with short tool projections for use where limited space is available.

Read MoreThe Most Common Types of Finishing Services for Precision Machined Components - Part 1 of 2

Cribsheet provided by PMPA member, Pioneer Service Inc. in Addison, Illinois

Read MoreThe Most Common Types of Finishing Services for Precision Machined Components - Part 2

Cribsheet provided by PMPA member Pioneer Service Inc., Addison, Illinois

Read More