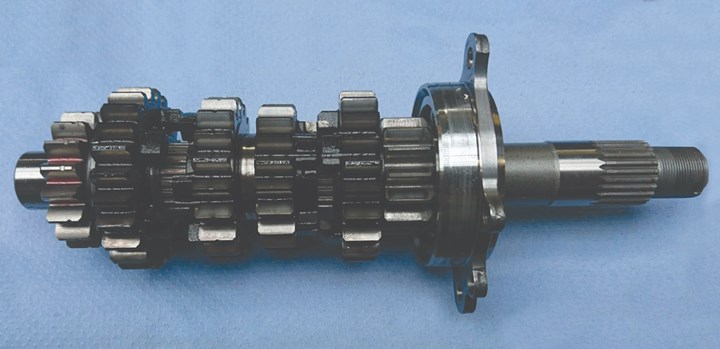

The stream finishing process improves the surface finish of gears to reduce friction and increase engine performance while reaching areas such as holes and roots of gear profiles. (Photo Credit: Sangha Race and Restoration)

Kieran Sangha, owner of Sangha Race and Restoration who builds high-horsepower motorcycle racing bike engines, knows that simply refurbishing and renewing parts rarely yields big performance gains. “Friction between components is an engine and gear killer,” Sangha says, who, when not transforming motorcycles for racing customers at his Leicester, UK, operation, enjoys the thrill of competition himself. He notes that component contact surfaces are under constant stress from powering through the gears while maintaining maximum revs as high as 18,000 rpm. This causes excessive heat which diminishes performance, can lead to component failure and could possibly cause rider injury if a mechanical fault was to occur.

Sangha previously tried to mitigate these problems by vibratory-finishing gears, shafts and engine parts. The process did improve component surface finish to a degree, but they still had a roughness that was noticeably uneven across a surface. Also, chemicals used with the media in the vibratory machines could weaken the metal and hardened surfaces. Disappointingly, component life span and bike performance remained unchanged.

“The molecules of the ceramic medium used in the vibratory-finishing process weren’t penetrating right into the root of the gear where we needed superfinished surfaces,” Sangha says. “I knew there had to be a better way to finish our gears and other race components.”

Sangha Race and Restoration improves engine performance by using the stream-finishing process when it remanufactures worn motorcycle engine and gearboxes. (Photo Credit: Sangha Race and Restoration)

Sangha found the solution when he turned to finishing specialist Fintek in the UK, a company that has been surface superfinishing parts for jewelry makers, aerospace component manufacturers and top motorsports teams for more than 30 years. Developments in this surface-finishing technology means it is increasingly affordable for smaller racing teams. One example is a technique called “stream finishing,” a process developed by German mass finishing equipment manufacturer Otec which is capable of achieving surface smoothness values to an average roughness of 0.01 micron Ra. It is also said to do this in a fraction of the time as traditional methods such as vibratory finishing or disc finishing. The process also has the added benefit in that it can eliminate stress-fracturing risks.

“In contrast to other finishing processes, stream finishing not only polishes the surface but positively changes the structure of the material edge zone,” says Otec managing director Helmut Gegenheimer. He explains that, as a result, it is possible to influence reduced peak height (Rpk) and core roughness (Rk) values and, therefore, a component’s fatigue strength. And, while the Ra value (the arithmetic average height of roughness-component irregularities) mentioned above can also be achieved by hand polishing, the Ra value does not give a true picture of the real surface profile. Identical Ra values can result in very different lubrication performance. An optimum peak structure (low Rpk values) generates the least wear and reduces friction losses, he says.

The Process

Stream finishing uses fine-grain media with a high density and a diameter of 0.2 to 1 mm — much smaller than media used in vibratory-finishing processes. Mixed with tensides and corrosion-protective media, the material looks similar to wet sand and is accelerated in the machine’s chamber. The workpiece or several workpieces are mounted on a workpiece holder and are immersed in the media at a specific angle. According to Gegenheimer, the speed of rotation of both the workpiece and the abrasive media — as well as the angle in which the parts are clamped and dipped into the chamber — depend on the application.

Stream finishing can achieve surface smoothness values of 0.01-micron Ra for parts such as gears. Reduced friction means less heat and up to 50% less noise. (Photo Credit: Sangha Race and Restoration)

“The abrasive media’s rotational speed controls the pressure on the workpiece and the workpiece rotation controls the cutting speed,” Gegenheimer says. “The generated high mechanical energy changes the crystal structure on the workpiece surface. Because the media is very fine grained, it reaches areas such as holes and the roots of gears. Stream finishing enables the so-called ‘third body’ to be formed more quickly between two surfaces in friction. This is the boundary layer where the surfaces (which are separated by a thin oil film) transfer their kinetic energy to each other. This flexing action makes the crystalline nanostructure of the layer extremely fine with a pasty viscosity, reducing friction.”

Stream finishing also eliminates the need for lengthy running-in of engines and gearboxes, which reduces oil contamination while extending oil change intervals by as much as 100%. An additional benefit is the 10% reduction in heat generated and as much as 50% reduction in noise emissions compared to conventionally ground parts, Gegenheimer explains.

Stream finishing also eliminates the need for lengthy running-in of engines and gearboxes.

Another advantage is the decrease in micropitting with gear wheels where the lubricating film breaks through at localized points causing mixed friction and excess pressure. This wear causes flattening at the contact point. The most important individual parameter related to this is the surface roughness. Values below 0.2-micron Ra, which Otec finishing typically achieves, can significantly reduce micropitting.

Here are examples of other parts that are commonly processed on an Otec’s stream-finishing machine. Fine-grain media with a high density and a diameter of 0.2 to 1 mm — much smaller than media used in vibratory-finishing processes — is used.

The process is designed for high-value parts, not for mass finishing of screws or other parts that are commonly mass finished with disc or vibration-finishing processes, which take a couple of hours. According to Otec, stream finishing only takes a minute or less. The process can be performed in two stages, whereby the first stage is a grinding process followed by polishing. “The polishing process reduces the peaks after the first process step (described above) even further,” Gegenheimer says. “It rounds down the peaks to reduce friction while maintaining the surface valley for good lubrication.”

To meet Sangha’s performance target, Fintek uses Otec’s stream-finishing process with a carefully balanced media size, angle of emersion in the media and cycle time. A surface smoothness of 0.02-micron Ra was achieved quickly, Sangha says.

An added bonus is the parts emerged with a highly attractive, polished, mirror-like appearance. To the touch, there was an extreme smoothness extending evenly across all surfaces, especially at the root of the gears, an area that other processes often fail to reach.

What did this mean for performance? Sangha explains, “Motorcycle racing is all about feel. An engine, gearbox and suspension might all work well, but you can instinctively tell there is a difference with extreme super-finished components. In testing, there was a considerable 5% performance increase. However, it is not just horsepower gains. It is also how quickly the engine makes power and how it feels when it is under load revving freely. Notably, it runs cooler, too. As a rider, confidence is critical. You can push it that little bit harder knowing the components and engine are reliable, something overlooked by many of my customers.” The stream-finishing process also helped to increase component life span. Less friction means reduced wear and less expensive maintenance and servicing.

Related Content

In-Machine Probing Possibilities for VTLs

A manufacturer of vertical turning centers uses a “push/pull” optoelectronic probe with custom bracket to enable its machines to perform effective, in-process measurement of shafts and related automotive components.

Read MoreSunnen Named Official Honing Equipment Partner of Hendrick Motorsports

Sunnen Products Co. adds its SV-series honing machines to the engine department of Hendrick Motorsports —which has earned a record 14 car owner championships in NASCAR’s premier division.

Read MoreThyssenkrupp Materials Services Opens New Facility in Texas

The new service center in Sinton, Texas supports the materials and supply chain management needs of manufacturing companies across multiple markets in the region.

Read MoreHow Small Machine Shops Can Fight Supply Chain Problems

Supply chain disruptions are still presenting challenges in manufacturing. This article examines the effects on aerospace, automotive and medical industries. It also covers ways that machine shops can be successful securing work despite the challenges created by the supply chain.

Read MoreRead Next

How to Choose and Set Up a Manufacturing Cleaning Process

Choosing the right cleaning process for an application takes thought and understanding. Knowing the basics of cleaning, the costs associated with it, as well as how to test, validate and inspect parts that are cleaned is critical. Teamwork and communication are also important in getting the job done efficiently.

Read MoreAutomatically Deburr, Clean Parts in One System

Palletized parts are transferred from a five-axis, high-pressure waterjet station to a cleaning station via linear motor to enable fast, automated finishing.

Read More5 Grinding Considerations for Improving Surface Finish

Improving surface finish can be done by making adjustments to one or more of these points: operational parameters, wheel dressing, grit size, coolant delivery and machine condition.

Read More