AI and Your QMS Procedures

Will artificial intelligence soon impact your quality system operating procedures? It could.

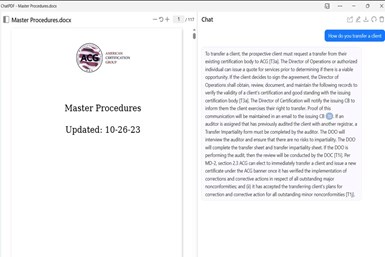

ChatPDF is an AI-powered tool that's designed to make your interaction with PDFs as simple as having a personal assistant that can read, summarize and even answer your questions about any PDF document. (Photo credit: American Certification Group)

Can an artificial intelligence program improve your quality management system (QMS)? If you agree that an effective, documented process should include responsibilities, action steps, as well as be understandable, accessible and accurate, then the answer is yes.

All documented QMS are built to ensure competent employees have access to information that describes job functions, responsibilities and specific action steps to ensure consistency. The problem is that we still live in a world in which there are reams of both current and historical documentation that is scattered among dusty binders and desktop computers. Much of this documentation is outdated, inaccessible, inaccurate and lacks detail. Accessing and effectively using quality management documentation can be a challenge.

It was decided that we would test our QMS using an artificial intelligence program.

We at the American Certification Group are not immune to the same problem, so we decided to stress test our quality management system to identify documentation that is inaccurate, redundant and lacks sufficient detail. It was decided that we would test our system using an artificial intelligence program.

ChatPDF is an AI-powered tool that's designed to make your interaction with PDFs as simple as having a conversation. It's like having a personal assistant that can read, summarize and even answer your questions about any PDF document. This is a web-based program, so if you are maintaining security protocols, you should review the use of this program with your IT professionals.

In our exercise, the QMS documentation, which includes policies, operating procedures and secondary procedures, was loaded into a single PDF file. For the sake of clarity, this entire set of documentation will be referred to as “process.” We wanted to stress test the entire QMS, not just one specific set of instructions. The steps were easy: Go to the ChatPDF homepage, upload the PDF that describes the process and start asking the system questions.

Our goal was to determine if a new associate with limited experience could quickly access accurate and understandable processes to any type of question relating to their job responsibilities. We found both positive and negative results:

- The level of detail. Our quality system documentation was originally developed by experienced personnel and was not written from the perspective of a person with minimal experience. Senior-level personnel who are aware of the process were able to ask the program specific questions and found the correct answers quickly. New personnel who lack experience asked questions that were more general. While the system found relevant information, it was clear that the level of detail did not effectively answer those questions. The language used was confusing to a new associate.

- Same process defined in multiple documents. The program would pull up information from multiple areas in our operating procedures and some process instructions would show up in multiple documents. Fortunately, those process instructions were consistent, but it did point out a potential problem. It would be easy to update a process in one document and forget to update that process in all the additional documents. Our philosophy is that a good process is only written once.

- Changing course. Generally, our instructions describe precise steps for a standard audit review and are weak at defining how to manage exceptions. The process lacked detail on how to pivot when a problem is encountered. Once we added the intended outcome to the process, it gave the associate perspective on how to follow the required steps and accurately make the correct decision.

Some people say that AI will destroy the world, but for this particular exercise, it did help us identify weaknesses that will make the working lives of our associates more efficient and effective. Our next step is to use the program during our internal audits. We want to have the auditor interview personnel as to how they process documentation and then feed their response into the program to make sure the documentation accurately reflects their response. Feel free to contact us if you would like to see the results.

About the Author

Joel Pecoraro

Joel Pecoraro is the director of operations at the American Certification Group (americancertify.com). He has been an auditor and trainer in quality management system development for over thirty years.

Read Next

Do You Have Single Points of Failure?

Plans need to be in place before a catastrophic event occurs.

Read MoreEmerging Leaders Nominations Now Open

Here’s your chance to highlight a young person in your manufacturing business who is on the path to be a future leader moving your company forward.

Read More5 Aspects of PMTS I Appreciate

The three-day edition of the 2025 Precision Machining Technology Show kicks off at the start of April. I’ll be there, and here are some reasons why.

Read More