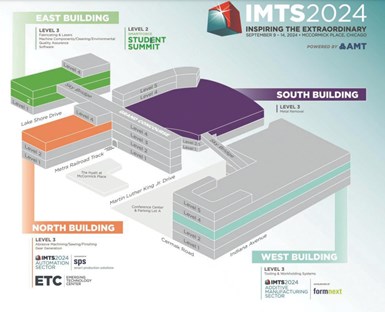

Automation in many forms will be on display at IMTS in September Learn more about the event at imts.com. Source: PM

It’s an understatement to say that the International Manufacturing Technology Show (IMTS) at Chicago’s McCormick Place is a big event. Having more than 1.2 million square feet of exhibit space, IMTS attracts visitors from more than 110 countries. The 2022 edition had 86,307 registrants and featured 1,816 exhibiting companies. It’s on pace to match those numbers in 2024 over its six-day span of September 9 to 14.

“To meet the needs of a robust manufacturing industry, IMTS 2024 will have even more exhibits that feature robotics, advanced motion systems, vision and imaging, data analytics, systems integration, software, artificial intelligence and connected technologies,” says Peter Eelman, chief experience officer for AMT – The Association For Manufacturing Technology, which owns and operates the show. “Every pressure on the manufacturing industry requires OEMs and job shops to implement technologies and processes that make them more efficient.”

Eelman’s mention of “processes” and “connected technologies” resonates with me as, over the years, IMTS exhibitors have increasingly focused on highlighting solutions more so than products. Yes, “solutions” sounds like marketing-speak. But if you’ve attended recent IMTS events, I’m sure you’ll agree it’s true especially if your company machines high volumes of parts instead of one-offs or prototypes.

One way this is represented at the show is in the multiple examples of ways that automation is more than robots. Certainly, robots are shedding the bad reputation of many years ago as they are now more flexible, easier to program and, in some cases, re-deployable to various machines. However, shops are also looking at more equipment such as tool presetters, on-machine part and tool probing, and automatic toolchangers for B-axis Swiss-type lathes as a way to eliminate manual tasks (and the risk of error) from the machining process. CAD/CAM software also continues to integrate more automated part programming functionality.

It's about establishing an effective overall machining process.

Similarly, more efficient measurement/inspection processes are being sought. Lights-out machining enables shops to get the most value out of their equipment and employees. But that often means there are many parts in the queue to be inspected. Part measurement can become an early-morning bottleneck that soaks up shopfloor workers’ valuable time. This has shops looking to new measurement technology that can speed and simplify part measurement (vision systems, for example) so workers can get back to other duties.

Machining is important, but so is part measurement for high-precision parts.

In addition, machine monitoring is a technology that helps pull it all together. Are your managers relying on gut feelings as they make decisions as to how shopfloor processes should be adjusted or are they using real data such as that pulled from machine tools to make more informed decisions? Even simply knowing and tracking when a machine’s spindle is cutting and when it isn’t in a given shift can be very helpful. This is the tool not only to bring all data together, but to determine how best to adjust shopfloor practices based on that information.

Recognizing process bottlenecks must happen before opening them.

Less a ‘Show’ Than an ‘Event’

Manufacturing trade shows such as IMTS feature new examples of software, tooling and machine tools and so on that exhibitors hope will catch the eye of attendees. But there’s more to it than presenting new products. Such events continue to expand in terms of networking and educational opportunities.

For example, IMTS 2024 features 11 conference programs in which attendees can learn from experts, grow their skills and network with their peers. These conferences highlight industry trends and provide advanced technical learning opportunities all without leaving the show.

The primary program is the IMTS 2024 Conference, which offers 68 sessions across five different tracks: Process Innovations, Alternative Processes, Plant Operations, Quality and Inspection and Automation. The IMTS 2024 Conference sessions runs Monday through Thursday at the event.

PM’s parent company, Gardner Business Media, is also hosting TASC — The Automated Shop Conference — on show Wednesday. This half-day event, put together by the team at sister brand Modern Machine Shop, focuses on introducing small and medium-sized machining operations to new product technologies, process innovations and business strategies that can help them implement lights-out machining and automated production. (Visit tascevent.com)

In fact, I approach IMTS with a process mindset. There are many industry friends with whom I want to reconnect, new people I hope to meet, article and video ideas I want to discover and soon after act upon and so on. I’m looking forward to engaging with this event, as I imagine you are as well.

Read Next

Do You Have Single Points of Failure?

Plans need to be in place before a catastrophic event occurs.

Read MoreA Tooling Workshop Worth a Visit

Marubeni Citizen-Cincom’s tooling and accessory workshop offers a chance to learn more about ancillary devices that can boost machining efficiency and capability.

Read More5 Aspects of PMTS I Appreciate

The three-day edition of the 2025 Precision Machining Technology Show kicks off at the start of April. I’ll be there, and here are some reasons why.

Read More