Aqueous System Handles Tight Cleaning Specs for Intricate Parts

This shop is using an ultrasonic cleaning and vacuum drying system to reduce the time involved in meeting its customer's recent changes to cleanliness requirements.

Original equipment manufacturers in the heavy equipment industry continue to demand stringent cleanliness requirements from their suppliers. Where 10 years ago, particle sizes of 1,000 microns captured in a millipore patch test might have been acceptable, today heavy equipment OEMs commonly demand maximum particle sizes of 600 microns or less. And where in years past, the gravimetric weight gain of particulate captured from the millipore test procedure may have had no defined limit, today that has completely changed. Now these same OEMs set gravimetric limits not to exceed 100 milligrams on components that are critical to the fuel, oil and airflow inside of engines, pumps and compressors. Tier 1 and 2 machining houses have had to respond accordingly.

Increasing Demands

The manufacturing and quality engineers at Stewart Manufacturing, a Hermansville, Michigan, machining house, found themselves in this situation recently when one of its best customers increased the cleanliness requirements for a family of cast iron turbo bearing housings that Stewart manufactures. The tighter cleanliness specifications meant that particles of more than 500 microns were no longer acceptable, gravimetric weight gain would be restricted to 25 milligrams, and no amount of abrasive material—in this case residual honing grit—would be allowed at all.

Before the customer made these changes to its cleanliness requirements, Stewart would clean the turbo bearing housings (after they were honed) using a 15-minute cleaning cycle inside a spray cabinet washer. However, this cycle time was inexact because often the spray washer did not successfully clean the parts in a single cycle. Thus, the bearing housings were often rewashed in a second 15-minute process.

Recognizing that it frequently took two wash cycles to clean these housings in their spray cabinet, and they were now faced with much more stringent cleanliness requirements, the engineers at Stewart understood that they would need to make a change to a high-performance cleaning system. They felt it would need to be able to flood every drilled passage of the various housings multiple times during a cleaning cycle and engage powerful ultrasonics to evacuate cast iron filings and all grit retained in the bearing housings after the honing process.

A New System

Stewart quickly began its search for a new cleaning system. “When an important customer is pleased enough with your finished product to give you increasingly more business, you don’t hesitate to dedicate the resources necessary to create a winning situation for both parties,” says Randy McLeod, Stewart’s vice president of manufacturing. Fortunately, they didn’t have to look far for a suitable system, checking first with the customer itself. “As for the more rigorous cleanliness standards, our belief was that our customer was probably achieving them inside their own manufacturing operations, so we inquired with our contacts there.”

Pleased with its own 2012 purchase of a MecWash Systems aqueous parts cleaning system, the customer suggested that Stewart research this line of parts washing equipment. Initially, Stewart believed a MecWash Midi would achieve its cleaning throughput and cleanliness requirements.

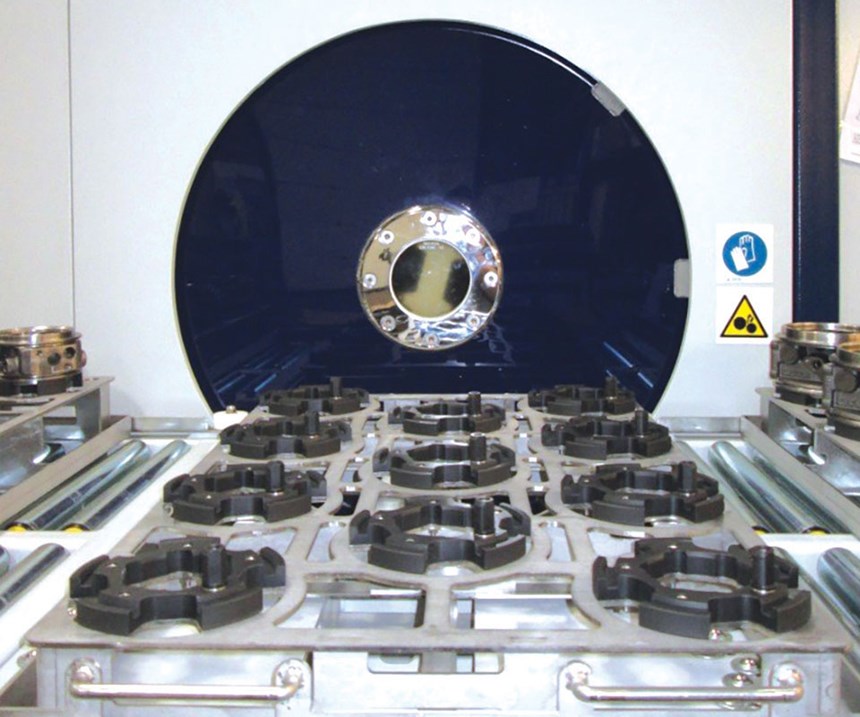

The Midi is a versatile, aqueous single-chamber rotational cleaning system that features ultrasonic flood wash and rinse, immersion wash and rinse, spray wash and rinse, hot air dry, and vacuum dry to eviscerate any retained water in small blind holes of components with more complex geometries. Stewart’s family of cast iron bearing housings did have blind holes, so a vacuum dry function would be an important part of an effective cleaning process.

As consideration of the Midi continued, however, Stewart’s business with its customers continued to expand. In the end, because of this additional business, Stewart decided to purchase a MecWash Maxi. The Maxi retains all of the performance of the Midi, but is constructed with a much larger cleaning chamber that measures 24-inch height by 24-inch width by 40-inch length. This larger design allowed Stewart to accommodate its expanding production requirements.

To successfully clean these cast iron bearing housings, holding them firmly in place during the full rotation throughout the entire cleaning cycle was critical. To meet this requirement, MecWash Systems designed four different purpose-built holding fixtures that would securely retain bearing housings measuring several different diameters.

The Maxi was installed at the Stewart facility in the spring of 2015. Since that time, it has been cleaning turbo bearing housings on every shift virtually non-stop.

For the smallest housing, the Maxi cleans 26 housings on two fixtures per 15-minute cleaning cycle. For the largest, the system cleans 12 housings on two fixtures per 15-minute cycle. Across the different housing diameters, the system can clean an average of 84 turbo bearing housings per hour. “Because of the Maxi’s high performance and huge cleaning capacity, we were able to offer Stewart a system that could both achieve its customer’s cleanliness requirements and surpass Stewart’s desired goal to be able to clean up to 80 turbo bearing housings per hour,” says Bill Westbrook, MecWash System’s North American operations director.

Related Content

Meeting Stringent Cleaning Goals With Modular Ultrasonic System

A knee implant manufacturer implements an advanced cleaning system that meets its tight cleaning requirements, including documenting, validating and tracing the entire cleaning process.

Read MoreSita’s CleanoSpector Measures Part Cleanliness

PMTS 2023: Handheld measuring device checks for cleanliness of parts to assure product quality as well as prior to follow-up processes.

Read MoreCool Clean’s Omega 1500 Provides Powerful, Portable Cleaning

PMTS 2023: By selecting the appropriate nozzle and making the necessary propellant pressure and temperature adjustments, the Omega 1500 can clean to a variety of surface cleanliness levels.

Read MoreMultisolvent 100 Vacuum Vapor Degreaser Provides Contactless Cleaning

PMTS 2023: With applications in the most demanding industrial sectors, the machine is especially useful for cleaning parts in the turning, precision mechanics, medical and aerospace industries.

Read MoreRead Next

Aqueous System Helps Clean Up the Process

With the right cleaning system, this company was able to reduce failure rate and rework costs while refining its production process.

Read MoreSeeing Automated Workpiece Measurement in Real Time

User-friendly inspection software for CNC machining centers was shown at IMTS 2024 monitoring measurements between and after machining while performing SPC based on recorded measurement values.

Read MoreDo You Have Single Points of Failure?

Plans need to be in place before a catastrophic event occurs.

Read More

.jpg;maxWidth=300;quality=90)