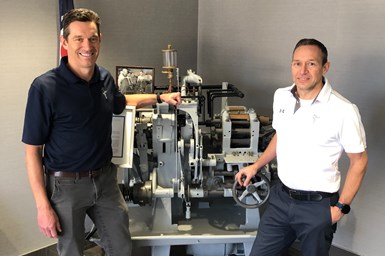

Brothers Rich (left) and Adam Gent have brought a wealth of new CNC technology to Gent Machine, a shop that initially relied solely on screw machines such as this Davenport displayed in its Cleveland facility.

Contract shop Gent Machine was established in 1927, but perhaps the biggest changes have occurred only in the last couple of decades.

In 2009, brothers Rich and Adam Gent purchased the company from their father, Richard Jr., who assumed ownership in the 1970s. The brothers’ great-grandfather and grandfather, Arthur and Richard Sr., respectively, started the business in South Euclid, Ohio, producing grenade fuses and firing pins.

Richard Jr. ran a successful operation using a couple dozen five-spindle Model B Davenports and employing as many as 20 people. During high school, the brothers worked there as machine operators. After college, they worked for a time outside the machining industry before returning to the family business. Rich came on board in 2000; Adam in 2006.

Gent Machine still has nearly 40 Davenport Model B machines (most with enclosures) in its new building.

That timing seemed ideal, as Gent Machine was thriving. Soon after, though, the shop’s largest customer that represented 65% of its business was purchased by another company that brought that machining work in-house.

“Those were hard times,” Rich says, “but, looking back, it’s those times that make you who you are.” And, it was that experience that led the brothers to consider ways to improve machining efficiencies and capabilities while diversifying its customer base to be able to withstand ever-changing business conditions.

Technology Transfer

Gent Machine’s specialty is turning bar stock ranging to 2 inches in diameter from steel, stainless steel, aluminum, brass, copper and titanium for industries, including automotive, firearms, industrial supply and hydraulics. The shop still has a number of Davenports as well as Acme six-spindle screw machines, but it has since added a wealth of new CNC equipment in a relatively short period of time.

“Our father wasn’t really into new machining technology,” Rich explains. “It’s not that he resisted it, but he didn’t want to implement entirely new processes as he was nearing retirement age. He looked to help us with implementation, though.”

The shop has nine Swiss-type lathes, one featuring technology that helps reduce the chance for creating long, stringy chips.

In 2007, a local customer spurred the shop to purchase its first CNC Swiss-type from Marubeni Citizen-Cincom to produce parts that couldn’t be machined on its existing equipment. Adam took on the challenge of learning that new technology, building the shop’s CNC department from the ground up after that purchase. Gent Machine now has nine Swiss-types, which enable the shop to produce more complex parts in smaller volumes compared to its older screw machines. (All of these Swiss-types were purchased through machine tool distributor Concentric Corp., also

located in Cleveland.)

Its newest machine features Marubeni Citizen-Cincom’s low-frequency vibration technology, which oscillates the cutter in the Z-axis in time to the rotation of the barstock. At times, it brings the cutter completely out of the cut. These intentional air cuts break the chips into consistently small pieces, so they can be readily expelled, minimizing the problems of spiraling chip entanglement around the workpiece or tool, known as “bird nesting.” Adam says all future Swiss-types will be purchased with this capability.

Additional changes were made to the company after the brothers purchased it from their father. By that point, Gent Machine had established a good mix of customers after spending a few years diversifying its base. Part of that was thanks to the revamped company website Adam created with improved search engine optimization. In fact, that’s how Tesla learned about the shop, finding its website and reaching out in 2011.

Although Tesla was looking for a supplier of injection molded parts, it did enable Gent Machine to get its foot in the door with the large electric vehicle original equipment manufacturer (OEM). Adam was able to develop a good relationship with a Tesla design engineer, and this eventually led to the shop winning work producing five different parts for Tesla.

Rich says it did represent a leap of faith on the shop’s part, however. For example, one job required an aluminum material purchase three times greater than the shop had ever made. In addition, Tesla was a startup at the time, and the viability of electric vehicles was still uncertain. That said, the shop took on the work, which required the purchase of three additional Swiss-types running three work shifts.

Gent Machine now has two rotary transfer machines, one fully CNC and the other hydraulically actuated.

This approach met Tesla’s production requirements, but perhaps wasn’t ideal. For years, the brothers had contemplated adding a rotary transfer machine. The time seemed right after they moved to a new, larger building in Cleveland in 2017, which offered 60,000 square feet of floor space compared to its cramped 22,000-square-foot operation (meaning there was room for a rotary transfer machine) and they also had a part which seemed ideal for that type of machine, spurring them to pull the trigger on buying one.

Gent Machine purchased a 16-station Hydromat Epic 45/16 through nearby machine tool distributor and turnkey system provider Motch and Eichele. The part this machine was set up to produce was a complex fastener originally machined on the Swiss-types. The shop was able to get the cycle time for this part on the Swiss-types down to 38 seconds, but the rotary transfer machine could complete parts in just 7 seconds. This enabled the shop to run only two shifts, while opening capacity on the Swiss-types for other work. It also enabled the shop to use insertable tooling compared to form tools because each machining unit can be set up to move in multiple axes.

Gent Machine then added its second rotary transfer machine: a hydraulic Hydromat Legacy 32/4-16. Although the job this second machine was purchased for fell through, the shop identified an existing airbag component it had been running on its Davenports in which production volume requirements were rapidly increasing.

Here is one of a few new machining units to be installed as part of re-tooling the CNC rotary transfer machine for a new job.

Similarly, at the time of my visit in April, the Epic machine was in the process of being retooled for a new job — a refrigerator hinge that has tight tolerances. The shop had been producing these hinges on its screw machines. One issue it had was a broaching process to produce two flats. As the broaching tool would wear, the dimensions on those flats would fall out of tolerance. The Epic is being fitted with a three-axis machining unit that can mill the flats and enable better process control.

Adding its First Mill

It’s not uncommon to see small CNC mills in high-production turning businesses being used to perform secondary ops on turned parts. Gent Machine, however, recently purchased its first vertical machining center (VMC) — a Hwacheon Vesta 660 having a 26" x 16.95" table — with a fourth-axis rotary table. This was initially bought to perform second-op work for ventilator components, but offers the possibility to perform production work.

The shop’s first VMC was purchased to do second-op work for ventilator parts.

This machine was also purchased through Motch and Eichele. The shop had planned to machine the ventilator parts complete on its twin-spindle/twin-turret machine. However, it decided it made more sense to do the turning and some cross-hole machining on that machine and then transfer it to the VMC to drill multiple other cross holes.

“The Vesta 600 provides additional capabilities that complement our shop’s turning equipment since a lathe is generally only able to use round or hexagon-shaped bars,” Rich says. “The mill provides increased capability as it is able to hold square and other shaped parts.”

Although the machine was purchased to be a profit center, it also enables the shop to find ways to decrease its costs to suppliers. A cap for a battery case is a good example.

As Adam explains, the shop made about 15,000 of these caps per month for a customer. Each part needed to be anodized, but not completely — only the top or “cap” side of the part was anodized. The rest had to remain bright. In order to do this, the bottom half of the part must be covered during the anodizing process. To cover the thread portion of the part, the anodizer screwed in hundreds of parts into its own fixture. The fixture prevents the bottom half of the part from being anodized. It dipped the fixture into the anodizing bath, unscrewed the parts from the fixture and sent the fixture back to the shop. The labor to screw in and unscrew each part was costly to the anodizer, so Gent Machine was billed for this time. The VMC enabled the shop to produce its own fixture. That way, it can install the parts in that fixture, send it to the anodizer, then receive the fixture with anodized parts for the shop to remove. This eliminated the anodizer’s labor charge, thereby reducing overall production costs.

Moving Forward

Today, the shop has 54 employees compared to 15 in 2009. Gent Machine has also expanded its assembly department. In addition, its current location offers ample room for more equipment. Although it’s not likely to add to its Davenport department, it could add another CNC rotary transfer machine at some point, if the right job comes along.

This automated, dual-camera measurement device from Resec Systems can perform 100% inspection on 10 types of parts. It measures part inner diameter, outer diameter and height automatically. Parts within specification are delivered via air blast to a

container. Parts that are out of specification are delivered to another container.

“We’re still relatively new to the rotary transfer scene,” Rich explains. “Service is key, especially when getting into new types of equipment, which is an additional reason we appreciate our long-standing relationship with Motch and Eichele, and purchased the Hydromats. Unlike shops that have been using rotary transfer technology for many years, we don’t have an inventory of machining units we could possibly use to retool our Hydromats for new jobs. But, it’s our goal to build that inventory and give us the speed and flexibility to convert our equipment to run different parts whenever we’d like to.”

Related Content

Automation Breakthroughs Revolutionize Precision Machining for Complex Parts

Marubeni Citizen-Cincom delivers custom solutions to address some of the biggest challenges in precision machining from handling small parts, to robot integration and unique tooling needs.

Read MoreWhen a CNC Turn-Mill Doesn’t Turn

A shop in Big Sky Country uses a B-axis multitasking machine to produce complex, prismatic medical parts that require no turning complete from barstock.

Read MoreDoes a Scanning Probe Make Sense on a Swiss-Type?

Swiss-types have limited tooling capacity, but there can be advantages to giving up some of that capacity to take advantage of a touch probe — in fact, a scanning probe — to enable in-process part measurements.

Read MoreVideo: Why a Production Machine Shop Started a Baseball Bat Company

A 153-year-old manufacturer of precision, metal pins recently started a side business creating custom wooden baseball bats. The reasoning behind establishing this new company is intriguing, as is how it has helped create a stronger bond with the local community.

Read MoreRead Next

Shop Continually Improves by Adopting Rotary Transfer Machines

American Turned Products’ founder left a legacy of continuous improvement, helping the company grow as it implemented rotary transfer machines and preparing it to take on new work.

Read MoreLow Frequency Vibration Increases Job Shop’s Productivity

With the ability to machine difficult materials more efficiently while improving surface finish, this job shop is reaping the benefits of its Swiss-type lathes that incorporate low frequency vibration.

Read MoreA Tooling Workshop Worth a Visit

Marubeni Citizen-Cincom’s tooling and accessory workshop offers a chance to learn more about ancillary devices that can boost machining efficiency and capability.

Read More

.jpg;maxWidth=300;quality=90)

.jpg;maxWidth=300;quality=90)