Automation Brings Reliability to Laser Marking Bone Screws

To overcome human error in laser marking, consider a reliable, high-throughput automated system designed to run 24/7.

Automation is popping up everywhere on machine shop floors, even serving manufacturing processes one might not expect. Laser marking machines, for instance, can be automated, which offers many benefits, especially for the medical industry.

A U.S. Food and Drug Administration regulation — the Unique Device Identification rule — states specific requirements for medical device manufacturers to label their products. For this reason, bone screws must be laser marked with information relevant to their manufacturer and the part identity in human-readable content. This information ensures the correct part is used not only during surgery but for traceability and recalls, if necessary.

Therefore, Foba Laser, a manufacturer of laser marking and engraving equipment, has developed a machine specifically for this job. According to the company, manual laser marking can be challenging, especially on small parts such as bone screws where laser markings as small as 300 to 500 microns in height are necessary to fit on a screw head. Manual laser marking, or material handling by an operator, can produce wrong, distorted or missing marked content.

For more reliable and accurate laser marking placement, as well as faster throughput, Foba says medical part manufacturers have discovered that automating this process produces the most successful results, especially when dealing with lot sizes of about 1,000. By minimizing operator interaction and integrating automation, exact positioning and alignment of the laser mark on bone screws are possible.

One example is the customizable automated laser marking machine Foba has developed specifically for bone screws. Not only does the system laser mark but it is also designed to validate the part, reorient and inspect the laser mark, says Faycal Benayad-Cherif, global strategic account manager at Foba Laser.

Validating, Marking, Inspecting

The automated laser marking system for bone screws is designed for high-volume, 24/7 use with light operator tending. Because the medical industry relies on accurately placed and legible part identification numbers on bone screw heads, the system was developed to produce highly precise laser markings.

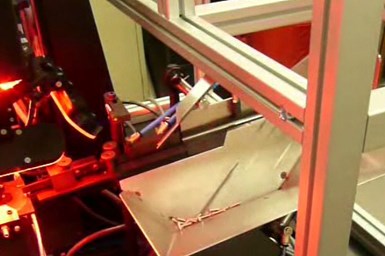

To start the bone screw laser marking process, an operator manually drops a lot size of screws into the bowl feeder (on the bottom right side of this image). The screws are then pushed by a knife in the machine into the channel to be validated, marked and inspected. Photo Credits: Foba Laser

The process begins with a manual operation, as an operator drops screws by hand, one lot a time, into the machine’s bowl feeder.

The bone screws, however, slide one by one into a feeder and are pushed into a moving channel. While in the channel, the screws are presented to the laser for marking: each screw is reoriented from a horizontal position to a vertical position by a combination of vibration and gravity, and then moved through a rotating channel that holds each screw head facing up.

To ensure that the correct screws are marked with the correct information, before marking, the system’s camera looks for screws that match the correct diameter and features according to the machine’s software program. It validates the screw family type and rejects the screws that do not belong with the group by ejecting them into the “fail” bin within the system.

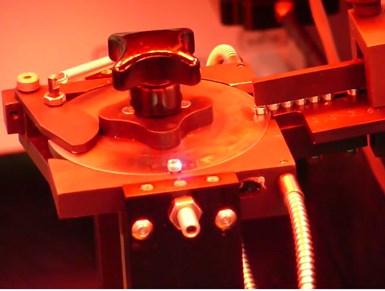

As the screws are moved through the system, they are laser marked by technology that automatically aligns the laser to the screw head, producing accurate and legible laser markings in the form of numbers.

This bone screw head (to the front of the photo) is being laser marked in the rotating channel within the machine. The FDA requires manufacturers to add traceability content on almost all medical devices.

Immediately after marking, the automated system completes optical character verification, which inspects the screws to ensure they have been marked properly. The machine’s camera looks for the content and validates each of the numbers laser marked on the screw’s head to guarantee accurate alignment as well as inspect the contrast to be sure it is legible. If a screw passes inspection, the machine drops it into a “pass” bin; if it does not meet the criteria, it gets dropped into a “fail” bin.

System Setup

Developed for easy use, this automated laser marking system has a push-button start, contains no fixtures and offers a small footprint of 1 meter by 1 meter. According to Benayad-Cherif, the goal of creating this machine was to provide an automated system that requires limited maintenance and involves minimum operator training and interaction.

Foba Laser’s custom automated laser marking machine for bone screws is compact, easy to use and set up, and designed for lot sizes as large as 1,000.

This system is designed to process a family of parts and includes functionality for a family length or diameter of screws. “You wouldn’t go from say a 3-millimeter to a 10-millimeter diameter screw, but you can go from a 3- to 5-millimeter diameter instead,” Benayad-Cherif explains. “So, the system has expected size limitations, but it is automated and that is the benefit.”

On some other, similar equipment where adjustments are required when changing over to a significantly larger part size, controls are kept simple and often do not require tools.

Running the equipment is also easy, according to Benayad-Cherif. The operator signs in using a company ID on the machine’s computer and then drops the bone screws in the feeder. At the computer screen, he/she scans a lot number with a barcode reader, which activates the machine’s laser marking process.

Related Content

Automation Breakthroughs Revolutionize Precision Machining for Complex Parts

Marubeni Citizen-Cincom delivers custom solutions to address some of the biggest challenges in precision machining from handling small parts, to robot integration and unique tooling needs.

Read MoreAutomation in the Alps: Studer AG Unveils New Grinding Concepts

Studer AG, member company of United Grinding, held its annual press conference at its Swiss Alps location earlier this month to announce its new automatic loaders to accompany its existing grinding machines as well as other offerings and automation features.

Read MoreReplace Repetitive Measurement With DIY Robotic Automation

After minimal training, a shop can learn how to use this robotic inspection system configured for a shopfloor application to supersede repetitive, time-consuming, high-mix gaging processes. It can then be redeployed for another application somewhere else in the facility.

Read MoreJob Shop Discovers and Fills a Fishing Need

The promise of a product line for improved mounting of electronic fish finders led this Missouri job shop to an automated turning process.

Read MoreRead Next

Fast Fixturing for Inspection and Laser Marking

The versatility of the Inspection Arsenal and Laser Arsenal modular fixture plate systems enables fixturing to be built on the individual grid plates. The plates can be easily removed from the magnetic docking rail when not needed.

Read MoreSeeing Automated Workpiece Measurement in Real Time

User-friendly inspection software for CNC machining centers was shown at IMTS 2024 monitoring measurements between and after machining while performing SPC based on recorded measurement values.

Read MoreDo You Have Single Points of Failure?

Plans need to be in place before a catastrophic event occurs.

Read More

.jpg;maxWidth=300;quality=90)